Dewaxing separation body inverted cone

A technology of separating body and inverted cone, which is applied in the direction of mechanical dehydration/demulsification, the axial direction of the swirling flow can be reversed, the swirling flow device, etc. It can solve the problems such as the complicated structure of the rotating separation device and achieve the volume of the equipment. The effect of small size, simple operation and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

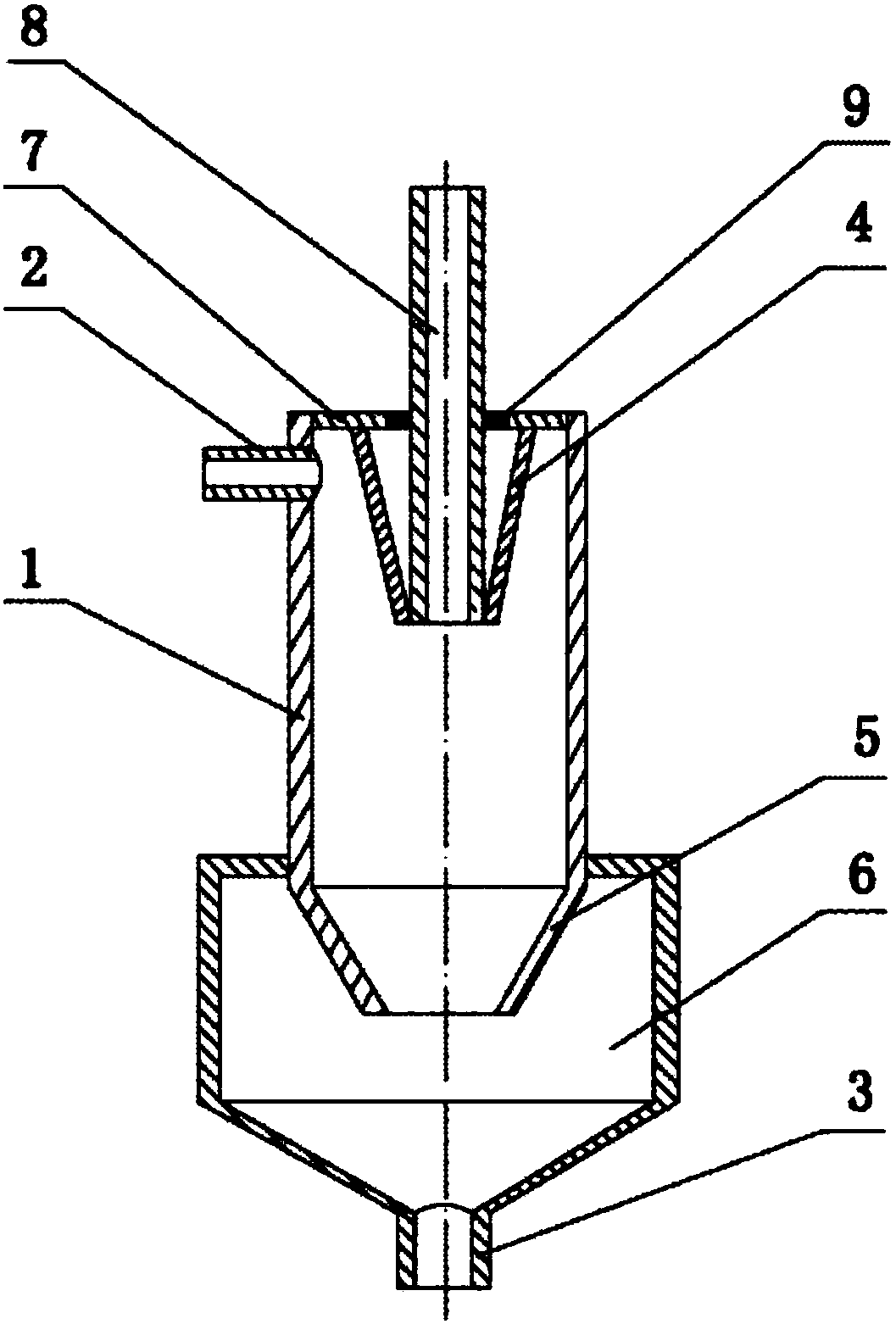

[0010] Such as figure 1 As shown, this kind of separator for petroleum microbial dewaxing includes a hollow cylindrical separation body 1 and a liquid collection chamber 6, and its unique feature is that: the upper end of the separation body 1 is fixed with an upper end cover 7, so The side wall of the separating body 1 is provided with an inlet pipe 2 connected tangentially to the outer circumference of the separating body, and the bottom of the separating body 1 is converging with a tapered mouth 5; the center of the upper end cover 7 is embedded with an inverted cone 4, the The bottom end of the inverted cone 4 is fixedly connected with an oil drop outlet pipe 8; the bottom of the separator 1 is connected to the top of the liquid collection chamber 6, and the conical mouth 5 penetrates into the liquid collection chamber 6, and the liquid collection chamber The bottom of 6 has liquid phase outlet 3.

[0011] In addition, a sealing ring 9 is installed at the joint between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com