Device for producing and finishing diaphragm spring

A technology of diaphragm springs and transmission parts, applied in the field of diaphragm spring production and finishing devices, can solve the problems of many restrictions, low production qualification rate, high equipment noise, etc., and achieves a high degree of automation, simple control, and improved speed and effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

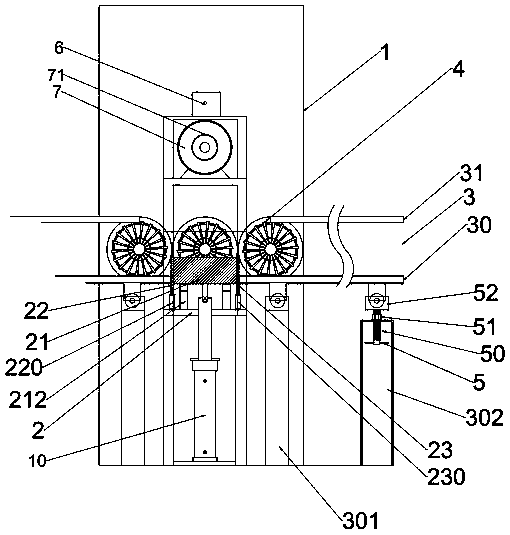

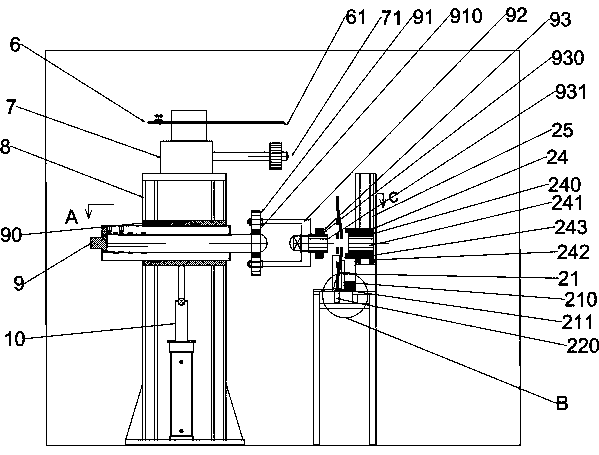

[0024] see figure 1 , a device for diaphragm spring production and finishing, including a work area 1, a workbench 2, a transmission part 3, a clamp part 3, a transmission part 4, and an angle adjustment part 5. The workbench 2 is provided with a front cylinder 230 and a rear cylinder 220 And the baffle support 212, the upper end of the piston rod of the front cylinder 230 is fixedly connected with the front baffle 23, the upper end of the piston rod of the rear cylinder 220 is fixedly connected with the back baffle 22, and the position of the workbench 2 is close to the back baffle 22. A photoelectric sensor 11 is provided, and a baffle 21 is provided on the upper end of the baffle support 212; a spring 210 with a telescopic rod is arranged behind the baffle 21, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com