Automatic batching machine for building construction

A technology for automatic batching and construction, which is applied to clay preparation devices, chemical instruments and methods, cement mixing devices, etc., and can solve the problems of difficulty in cleaning batching machines, splashing of internal mixtures, and lack of sealing devices at the discharge outlet. Safe and convenient, high mixing efficiency, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

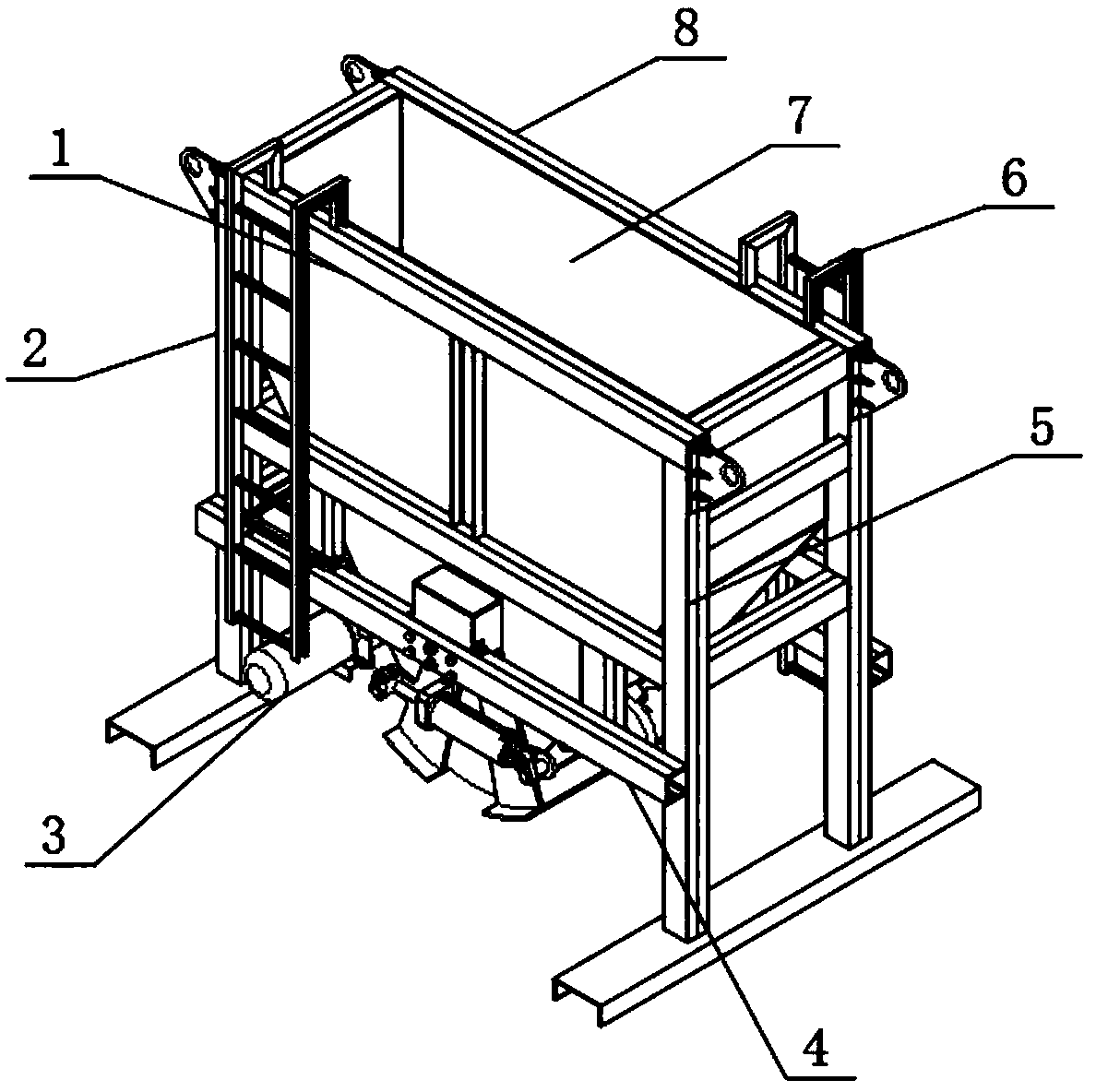

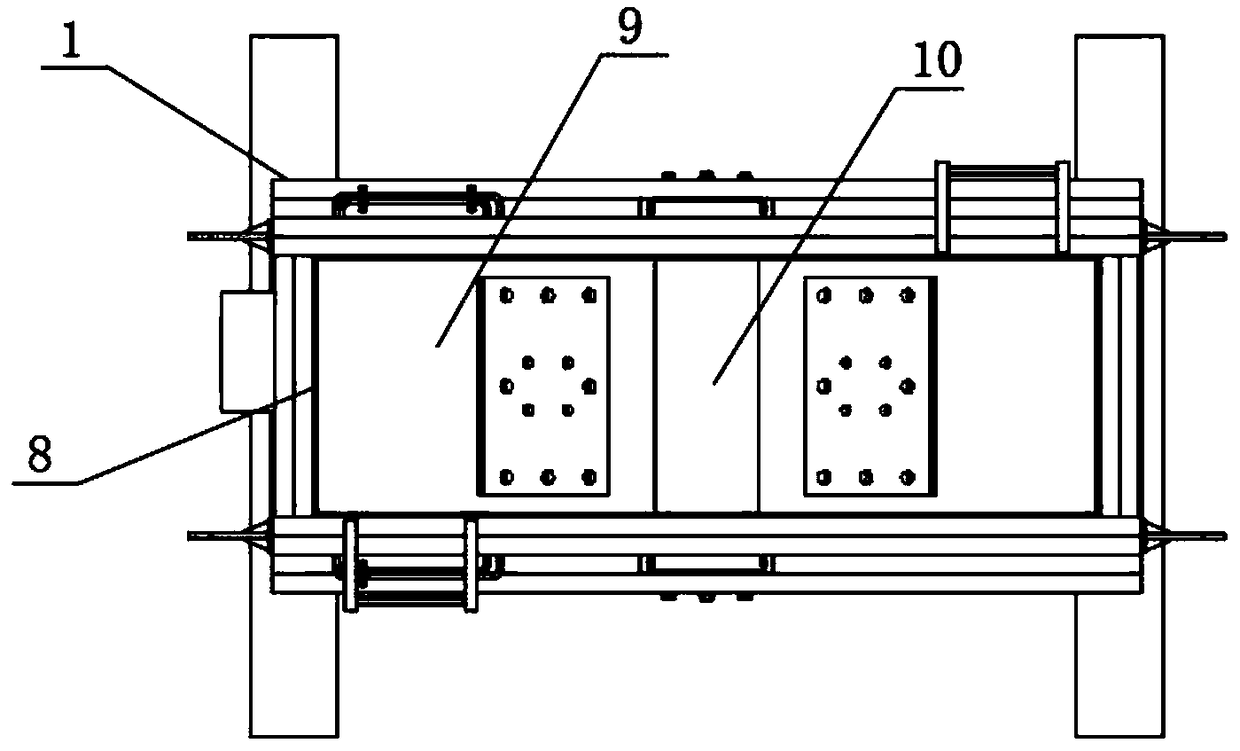

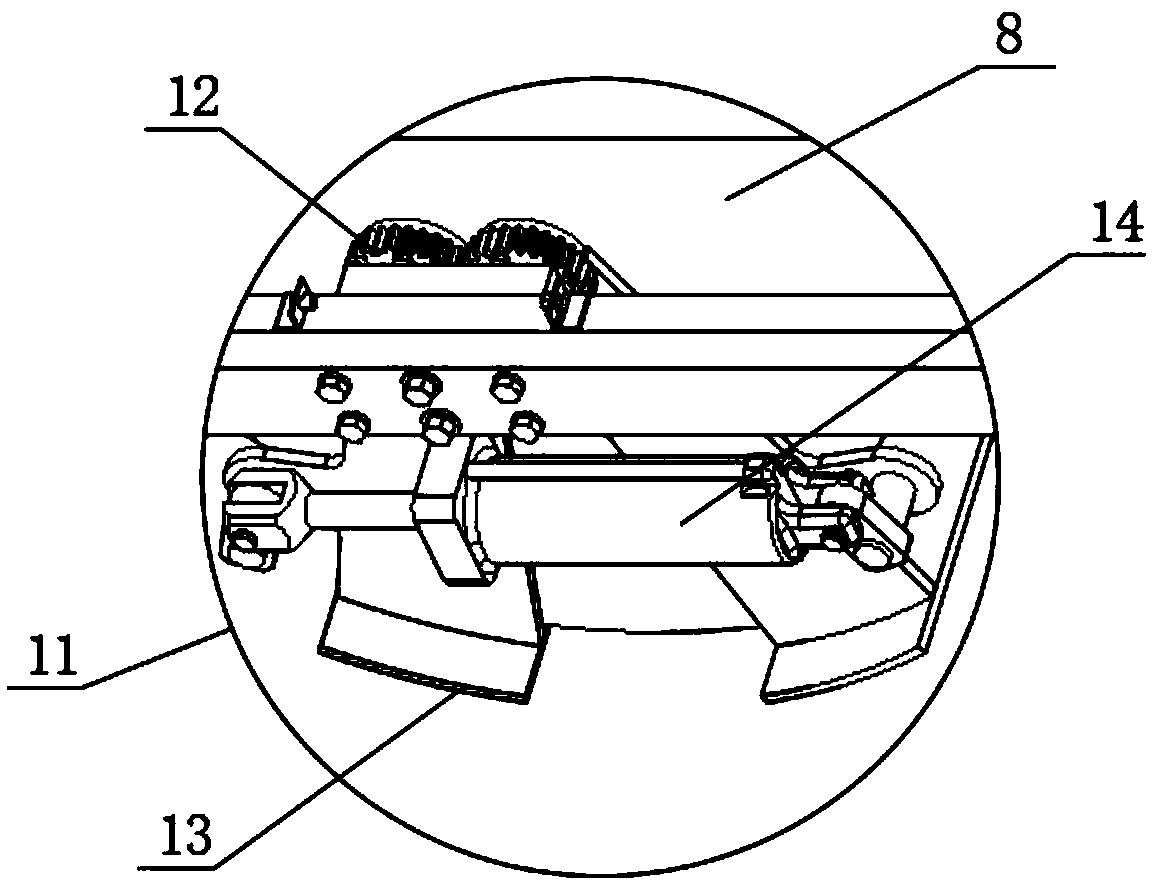

[0019] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution: an automatic batching machine for building construction, including a frame 1 and a batching cabinet 8 fixed on the frame 1 by bolts, and escalators A2 are fixed on both sides of the frame 1 by bolts And the escalator B6 is convenient for the staff or maintenance personnel to clean and overhaul the batching cabinet 8, or check the operation of the machine; the frame 1 includes four columns 5 arranged in a rectangle and multiple columns fixed between the columns 5 Crossbar 4; the top of batching cabinet 8 is material inlet 7, and its bottom is discharge port 10, and the inside of batching cabinet 8 is the batching warehouse 9 that is communicated with feed inlet 7 and discharge port 10 respectively; The bottom end is an arc-shaped structure, and the drive motor 3 is respectively fixed by bolts on both sides thereof; the sealing mechanism 11 is fixed by ...

Embodiment 2

[0025] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution: an automatic batching machine for building construction, including a frame 1 and a batching cabinet 8 fixed on the frame 1 by bolts, and escalators A2 are fixed on both sides of the frame 1 by bolts And the escalator B6 is convenient for staff or maintenance personnel to clean and overhaul the batching cabinet 8, or check the operation of the machine; the frame 1 includes four columns 5 arranged in a rectangle and multiple columns fixed between the columns 5 by welding root cross bar 4; the top of batching cabinet 8 is material inlet 7, and its bottom is discharge port 10, and the inside of batching cabinet 8 is the batching warehouse 9 that is communicated with feed inlet 7 and discharge port 10 respectively; The bottom end of 8 is an arc structure, and the drive motor 3 is respectively fixed by bolts on both sides thereof; the sealing mechanism 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com