A kind of preparation method of toilet cotton soft towel

A technology of soft towels and toilet cotton, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as waste of resources, environment, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

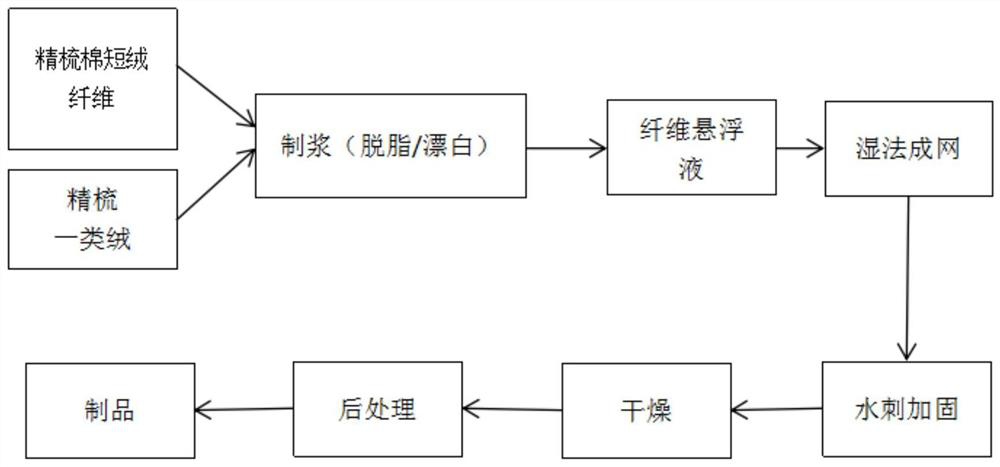

[0036]Method for preparing to toilet cotton scarves, such asfigure 1As shown, it includes the following preparation steps:

[0037]A, 浆: According to the mass parts, 95 combined cotton velvet fibers and 5 comblicvelopted cotton gentle fibers plus 200 water hydraulic pulp are mixed and stirred and mixed, then add degreasing bleaching The reagent performs skim bleaching treatment on cotton hair, fed into the filtration system to screen the sand and impurities to obtain a cotton cellulose slurry, and finally passed into the flushing pump into the fine slurry of cotton cellulose slurry. Nearing in the storage pulley;

[0038]Among them, the length of combed cotton short fibers is less than or equal to 6mm, and 3-6mm long combed cotton short fibers account for 55% of the total mass of the combed cassets, which is dispersed; combed one type of cotton short The length of the velvet fiber is 13mm and is a dispersed state;

[0039]B. Formulated Fiber Suspension: Add a citric acid pH regulator to the ...

Embodiment 2

[0046]A method of preparing an inner cartoon sloth, Example 2 and Example 1 Different in the first embodiment, in step A, according to the mass parts, the addition of combed cotton short fibers is 90 copies, combing a class The amount of cotton spline fibers is 10 parts; the water thorn pressure of the water stabble in step d is 50, the thickness of the cotton schedrals made of 0.36mm, the finished product gram is 55g / m2.

[0047]The other preparation steps in Example 2 were the same as in Example 1.

Embodiment 3

[0049]A method of preparing a canula cotton sloth, Example 3 and Example 2 Different in the first embodiment, in step A, according to the mass parts, the addition of combed cotton short fibers is 85 parts, combed a class The amount of cotton spline fiber is 15 copies, and the thickness of the cotton tissue made is 0.35mm, and the finished product grams is 55g / m.2.

[0050]The other preparation steps in Example 3 were the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com