Pressure-maintaining circulating grouting method

A technology of grouting and grouting holes, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve problems such as difficulty in maintaining stable grouting pressure and small amount of grouting, achieve good reinforcement effect, avoid pollution, and save energy. material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Next, the pressure-holding cycle grouting method of the present invention will be described in detail with reference to the accompanying drawings.

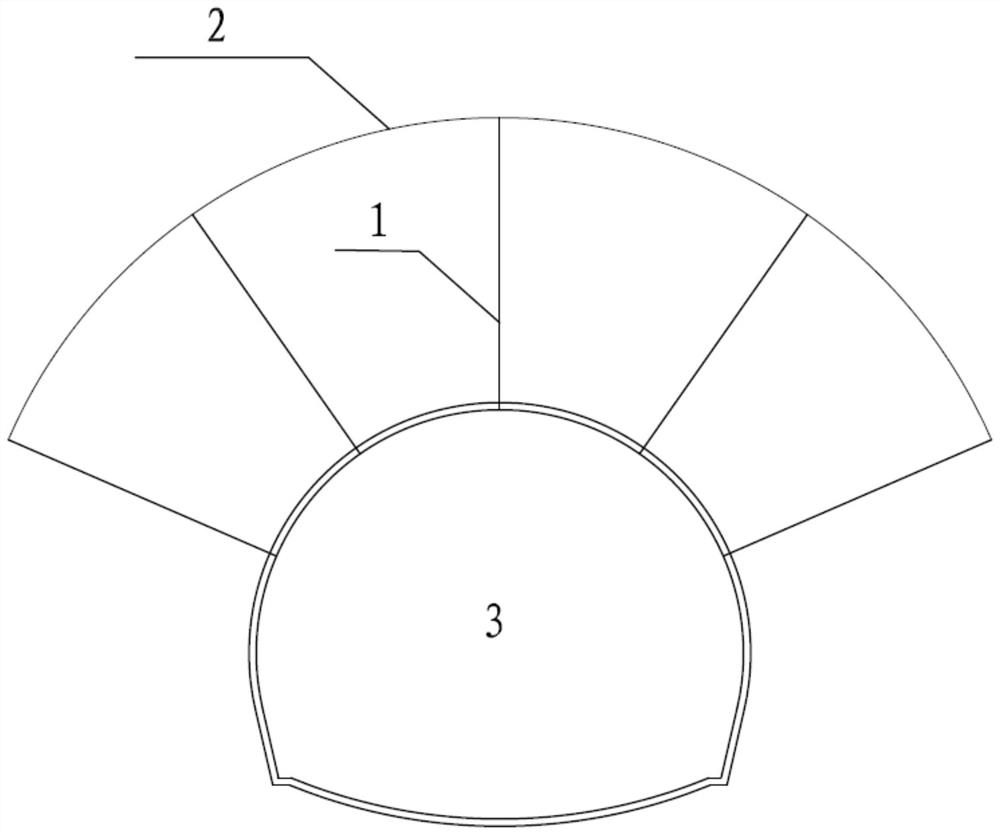

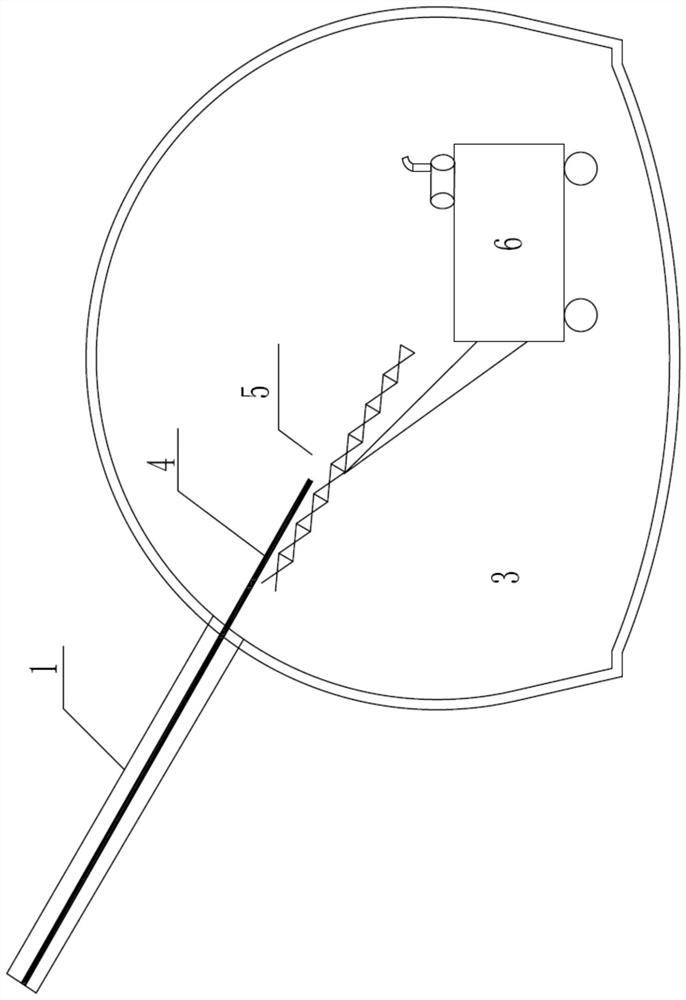

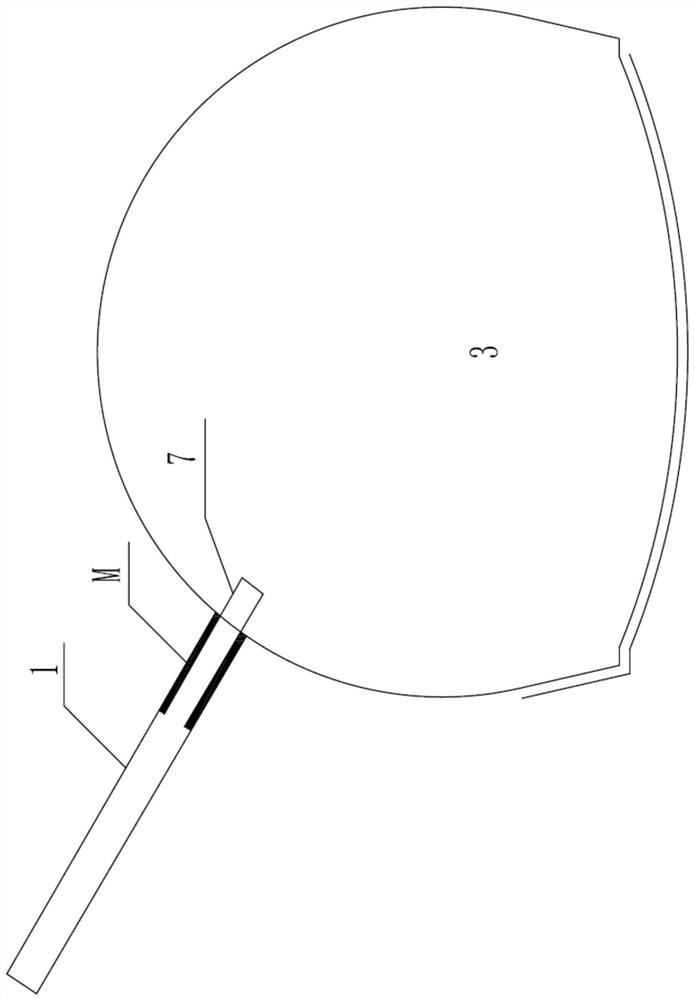

[0037] First, if Figure 1A As shown, according to the purpose of grouting water blocking or reinforcement, taking tunnel 3 as an example, the drilling design of grouting hole 1 is carried out in the pre-construction area with reference to water blocking or reinforcement contour line 2, and the drilling distance of grouting hole 1 needs to be Considering factors such as the degree of fracture development, the hydraulic pressure of groundwater, the porosity of the soil, and the designed grouting pressure, the drilling depth mainly considers the range of pre-sealing or reinforcement. Next, if Figure 1B As shown, according to the designed drilling parameters of the grouting hole 1, accurate measurement and lofting are carried out. After the drilling rig 6 is in place, adjust the drill pipe 4 and the power head 5 to the design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com