Lifting appliance for sand cores

A sand core and spreader technology, which is applied in the directions of load hanging components, transportation and packaging, can solve the problems of inability to accurately locate and hoist the sand core, low work efficiency, air leakage, etc., and achieve convenient off-line hoisting. The effect of transportation and fast clamping and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

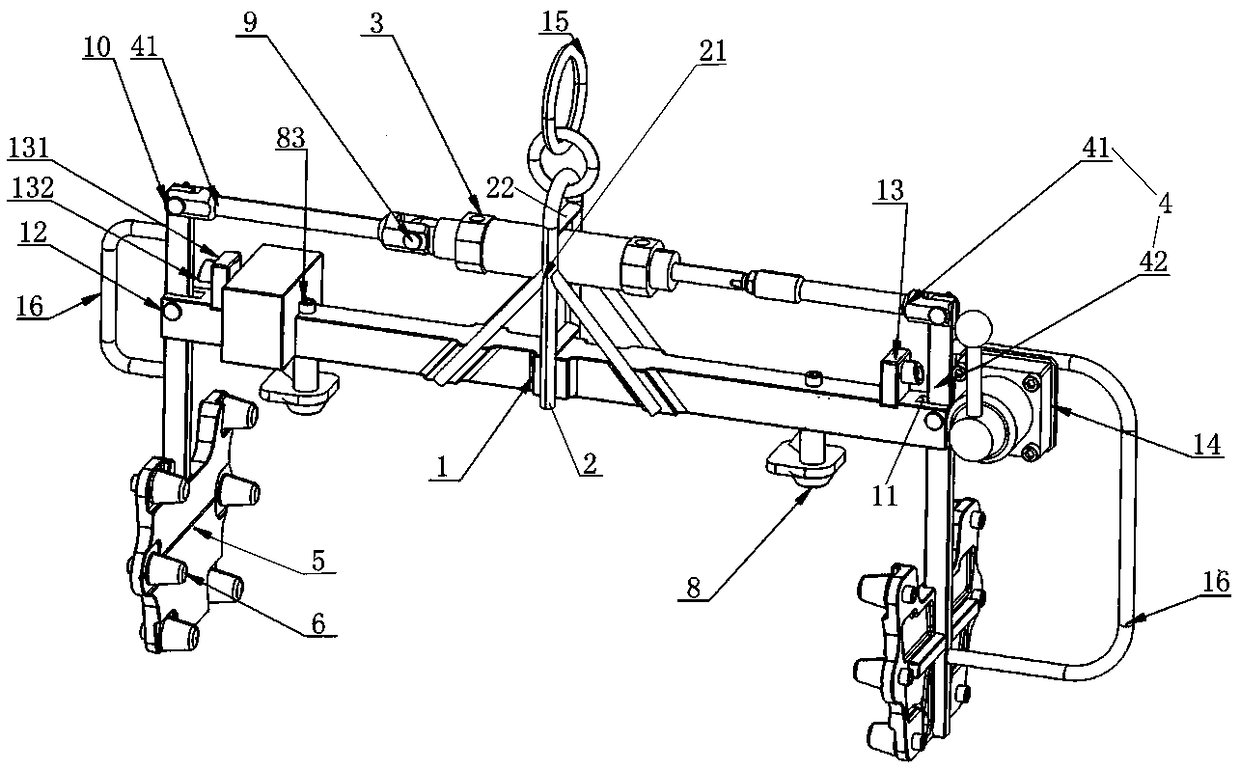

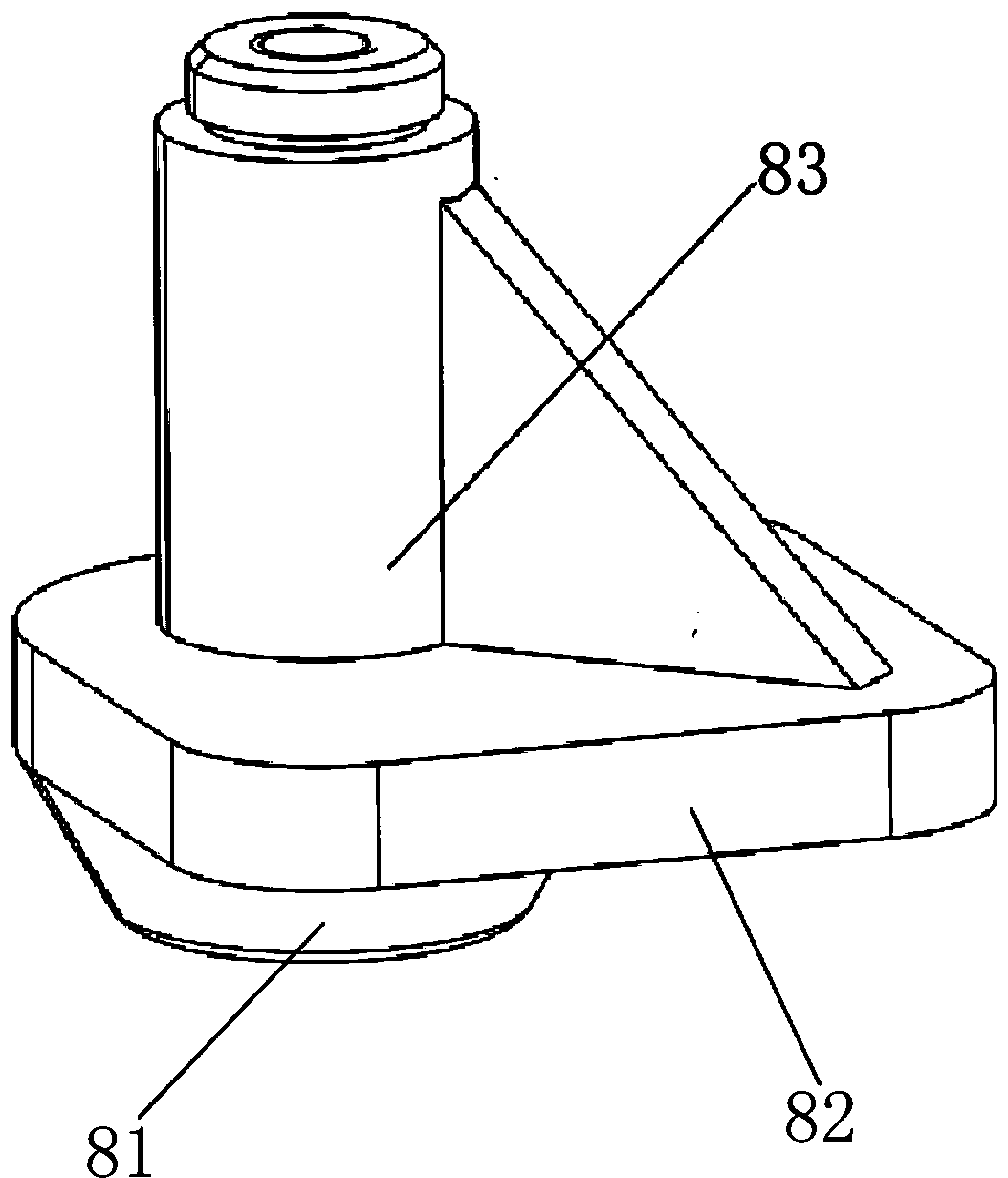

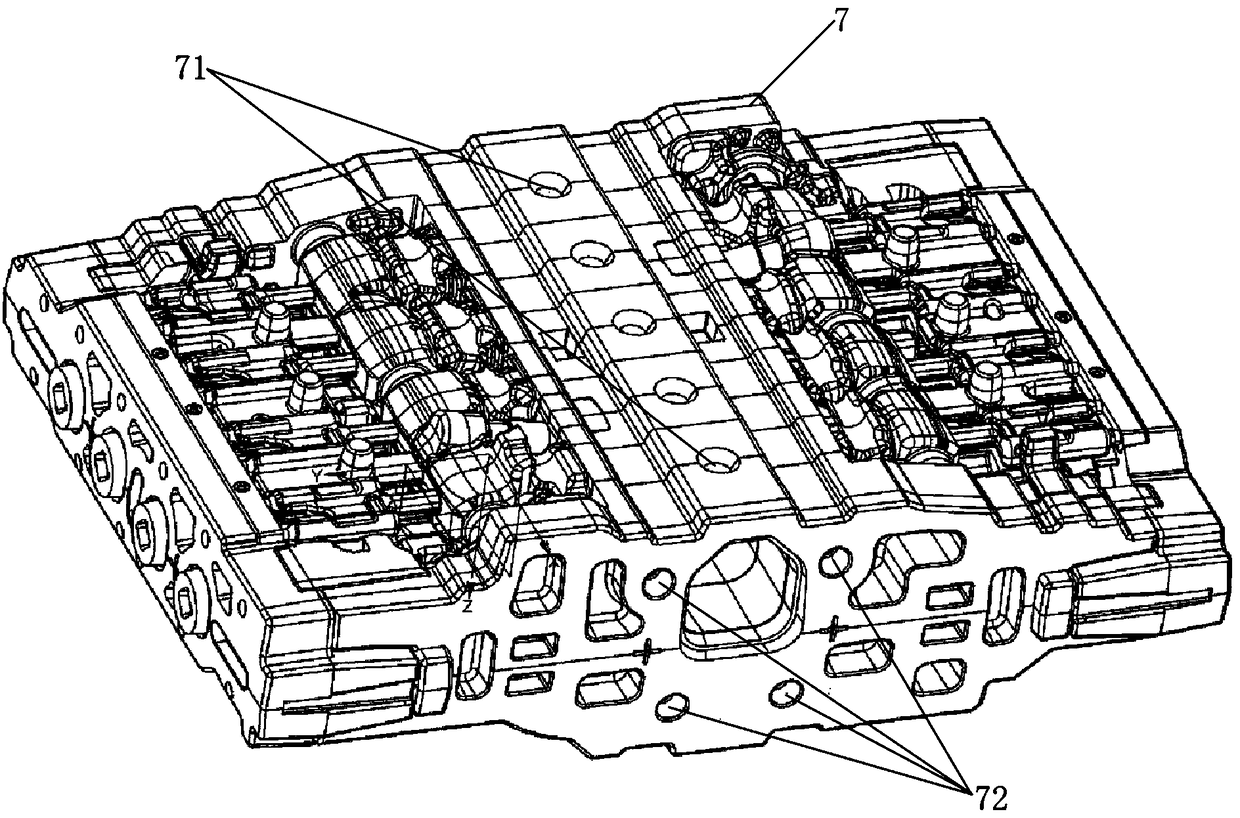

[0023] see Figure 1-3 .

[0024] The invention discloses a sand core hanger, comprising a beam 1, a fixed bracket 2 arranged in the middle of the beam 1, a cylinder 3, a connecting rod 4, and a hook fixing seat 5; the cylinder 3 passes through the fixed bracket 2 Fixed on the top of the beam 1, and parallel to the beam 1, both ends of the cylinder 3 are provided with piston rods, and the ends of the piston rods are respectively hinged with one end of the connecting rod 4; Rod 4 comprises horizontal connecting rod 41, vertical connecting rod 42, and one end of described horizontal connecting rod 41 is hinged with piston rod, and the other end is hinged with the top end of described vertical connecting rod 42, and the side of described vertical connecting rod 42 The wall is hinged with the end of the beam 1; the bottom end of the vertical connecting rod 42 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com