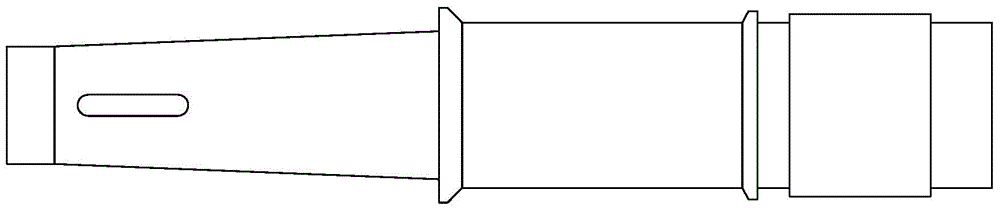

Tool fixture used for machining key groove of taper shaft

A groove machining and taper technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as the surface quality of parts affecting the machining accuracy, difficulty in clamping and calibrating wheel axles, and unreliable clamping, etc. Easy and labor-saving operation, reduced labor intensity, reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

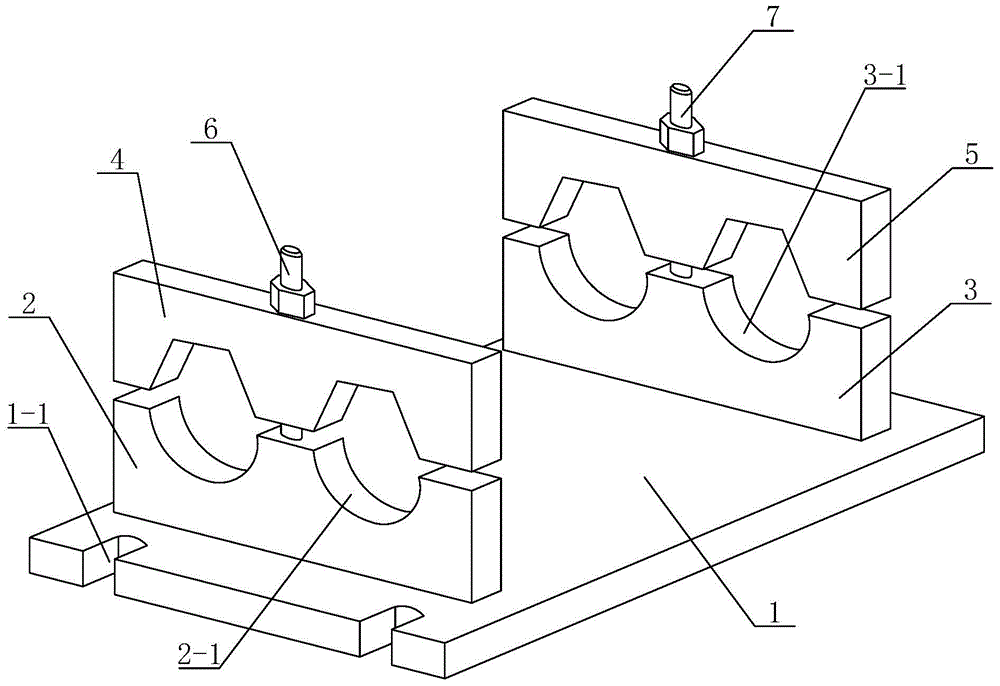

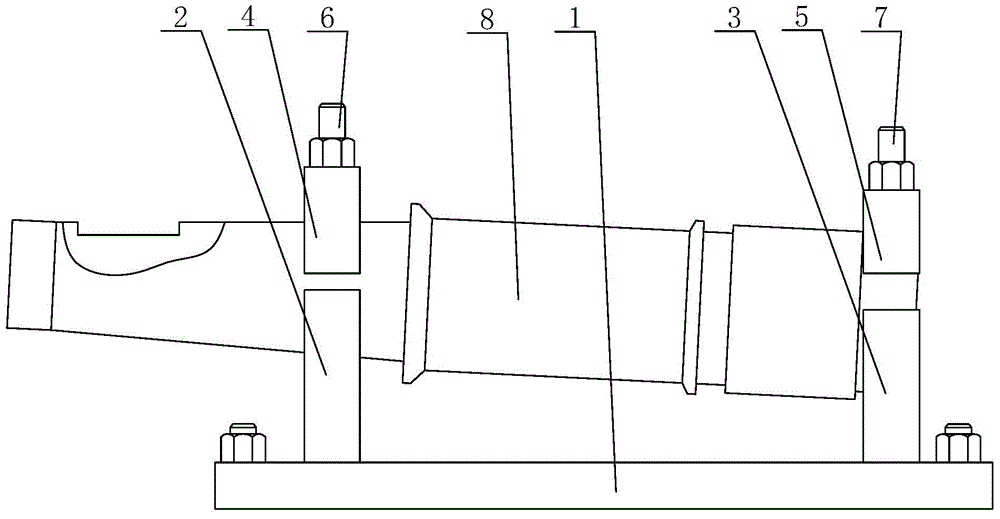

[0022] Such as figure 2 and image 3 The shown tooling fixture for processing taper shaft key grooves includes a bottom plate 1 which acts as a fixed bearing, and also includes support seat one 2 and support seat two 3 arranged in parallel for supporting the taper shaft 8, and support seat one 2 Cooperate with the V-shaped groove pressing plate one 4 for pressing the tapered shaft 8 and the V-shaped groove pressing plate two 5 for pressing the tapered shaft 8 with the support seat two 3; the support seat one 2 and the support Seat two 3 are respectively fixedly arranged on both sides of the upper part of the base plate 1, and the upper side of the support seat one 2 is provided with at least one positioning arcuate surface 2-1 having the same taper as the tapered shaft 8 tapered surface, the same taper It can ensure that the tapered surface of the tapered shaft 8 is in a horizontal position. The upper side of the support base 3 is provided with an end face positioning hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com