Quickly assembled chuck

A fast, driving device technology, applied in the field of tooling and fixtures, can solve the problems of low carrier installation efficiency, low product processing accuracy, and reduced positioning accuracy, and achieve the effects of convenient processing and manufacturing, fast clamping and positioning speed, and reduced positioning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

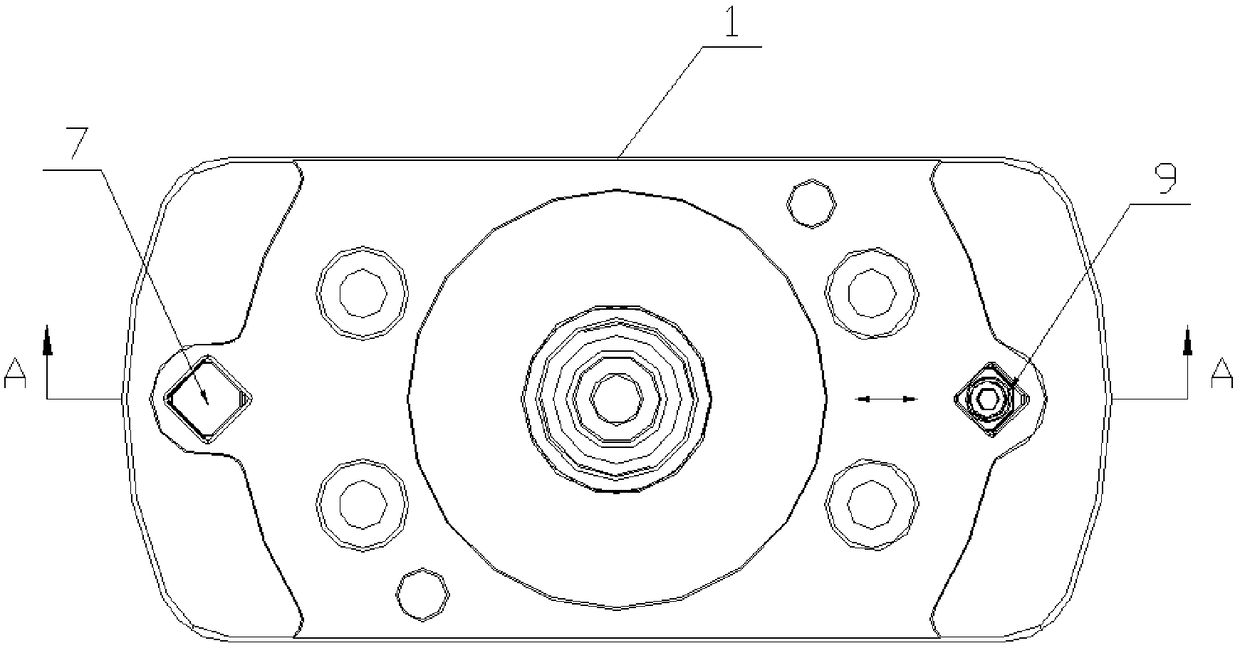

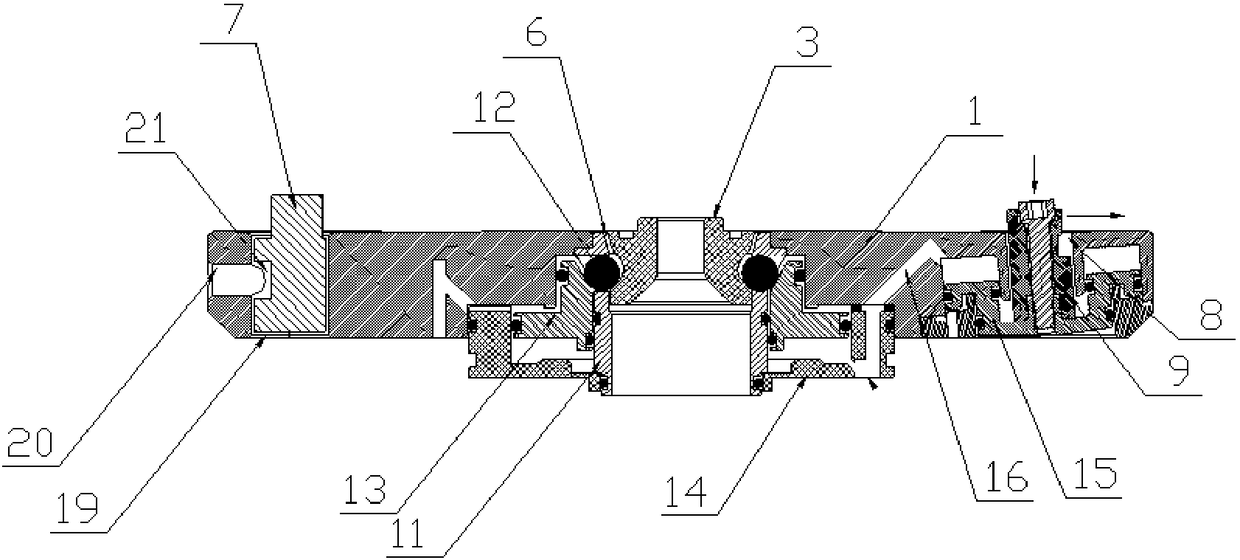

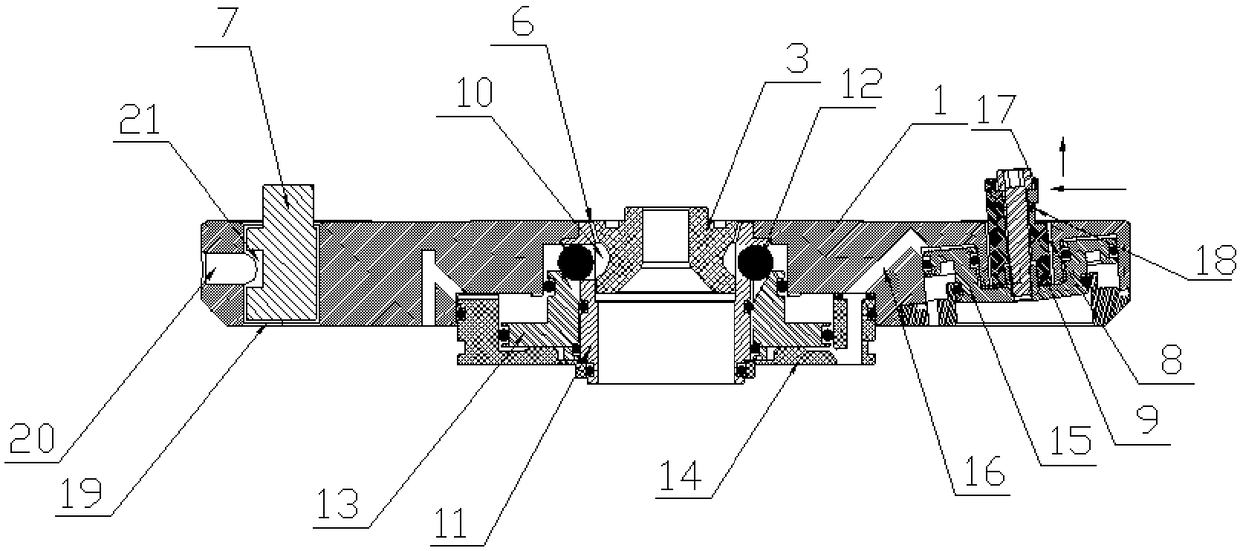

[0020] Embodiment: A quick clamping chuck, including a main body 1 and a carrier 2, the carrier 2 can be placed on the upper surface of the main body 1, and the lower surface of the carrier 2 is fixed with a pull stud 3. The carrier 2 is also provided with a first pin hole 4 and a second pin hole 5 with a non-circular cross-section extending in the vertical direction, and a vertically extending pin hole is provided on the upper surface of the main body 1. Slot 6, the slot 6 is provided with a buckle structure and a buckle drive device, the pull stud 3 on the lower side of the carrier 2 can be inserted into the slot 6 of the main body 1 and along the vertical direction with the buckle structure The snap-fit connection of the stop, the snap-in driving device can drive the snap-in structure in the slot 6 to snap-in or release with the upper pull stud 3 of the carrier 2, and the upper side of the main body 1 is also fixed with a non-circular cross-section The fixed pin 7 is inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com