Flowing light and color porous elastic gradient ring fancy yarn and manufacturing method thereof

An Ambilight, fancy yarn technology, applied in yarn, textile and papermaking, weft knitting and other directions, can solve the problems of poor dyeability, poor elasticity, and insufficient hot and water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

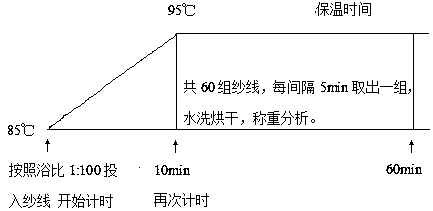

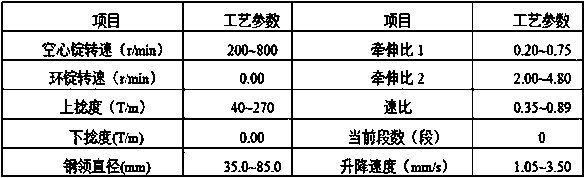

[0100] A method for preparing an ambilight porous elastic gradient bouquet yarn, the steps are as follows:

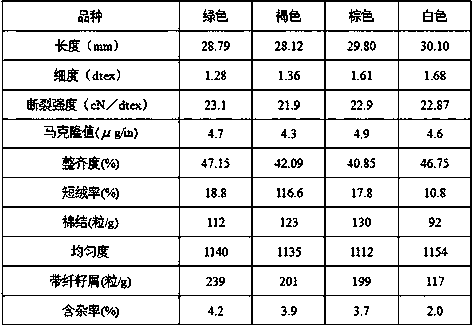

[0101] A kind of "ambilight" blended with hemp fiber, antibacterial hollow polyester fiber, natural colored cotton fiber, spandex filament, bamboo charcoal negative ion viscose filament, mohair fiber, silver-loaded antibacterial polyester fiber, and water-soluble vinylon fiber filament. "Porous elastic fancy gradient ring antibacterial negative ion health care yarn is taken as an example, wherein the core yarn is laima hollow polyester colored cotton elastic core-spun yarn, and in the blended laima hollow polyester colored cotton elastic core-spun yarn, laima The weight content of fiber accounts for 30%, the weight content of antibacterial hollow polyester fiber accounts for 30%, and the weight content of natural colored cotton fiber accounts for 40%; the fixed yarn is bamboo charcoal anion viscose filament; Silver antibacterial polyester fiber (water-soluble vinylon fi...

Embodiment 2

[0103] A method for preparing an ambilight porous elastic gradient bouquet yarn, the steps are as follows:

[0104] A kind of "ambilight" blended with hemp fiber, antibacterial hollow polyester fiber, natural colored cotton fiber, spandex filament, bamboo charcoal negative ion viscose filament, mohair fiber, silver-loaded antibacterial polyester fiber, and water-soluble vinylon fiber filament. "Porous elastic fancy gradient ring antibacterial negative ion health care yarn is taken as an example, wherein the core yarn is laima hollow polyester colored cotton elastic core-spun yarn, and in the blended laima hollow polyester colored cotton elastic core-spun yarn, laima The weight content of fiber accounts for 37%, the weight content of antibacterial hollow polyester fiber accounts for 38%, and the weight content of natural colored cotton fiber accounts for 25%; the fixed yarn is bamboo charcoal anion viscose filament; Silver antibacterial polyester fiber (water-soluble vinylon fi...

Embodiment 3

[0106] A method for preparing an ambilight porous elastic gradient bouquet yarn, the steps are as follows:

[0107] A kind of "ambilight" blended with hemp fiber, antibacterial hollow polyester fiber, natural colored cotton fiber, spandex filament, bamboo charcoal negative ion viscose filament, mohair fiber, silver-loaded antibacterial polyester fiber, and water-soluble vinylon fiber filament. "Porous elastic fancy gradient ring antibacterial negative ion health care yarn is taken as an example, wherein the core yarn is laima hollow polyester colored cotton elastic core-spun yarn, and in the blended laima hollow polyester colored cotton elastic core-spun yarn, laima The weight content of fiber accounts for 40%, the weight content of antibacterial hollow polyester fiber accounts for 45%, and the weight content of natural colored cotton fiber accounts for 15%; the fixed yarn is bamboo charcoal anion viscose filament; Silver antibacterial polyester fiber (water-soluble vinylon fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com