Anti-freezing system for roads and bridges

A highway bridge and anti-icing technology, applied in bridges, bridge parts, bridge construction, etc., can solve serious accidents, low freezing efficiency and other problems, achieve long service life, improve deicing effect, and reduce the possibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

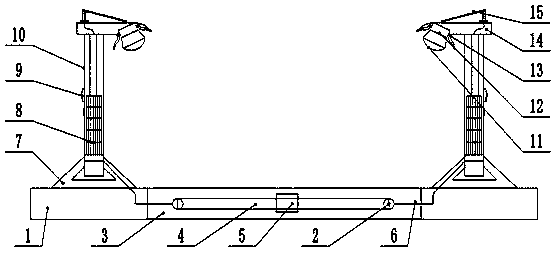

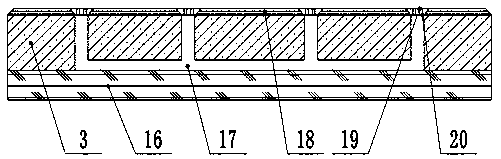

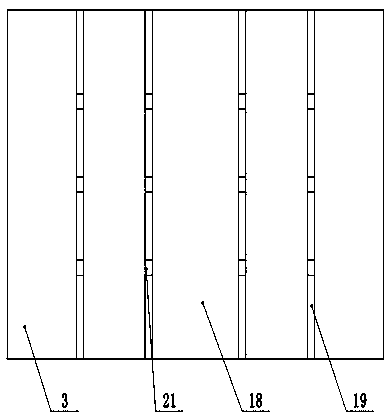

[0021] see figure 1 , an anti-freezing system for highway bridges, comprising: a street lamp support base 1, a roadbed 3, a support base 7, a street lamp column 10 and an installation platform 14, the roadbed 3 is the road above the bridge, and the two sides of the roadbed 3 A street lamp support base 1 is provided, and a support base 7 is fixedly installed on the top of the street lamp support base 1. The middle part of the support base 7 is fixedly installed with a street lamp column 10 through Luo Shuanggroup. The street lamp column 10 adopts angle steel as a frame, and the surface is fixed Steel plates are installed, and the surface is coated with antirust paint. The upper end of the street lamp column 10 is fixedly installed with an installation platform 14, and the upper end of the installation platform 14 is provided with a solar panel 15. The solar panel 15 adopts an inclined design, facing the sun's inclination direction, wherein the height of the rear support frame c...

Embodiment 2

[0024] Further, the support seat 7 adopts a triangular structure, which has strong stability and improves the stability of the street lamp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com