Heat insulated building for heavy oil well

A technology for thermal insulation rooms and oil wells, which can be applied to special buildings, small buildings, building types, etc., and can solve problems such as delays in heavy oil well production, real-time monitoring of heavy oil wells, freezing of oil pipelines and gas pipelines, accidental injuries to personnel, etc. Achieve the effect of convenient construction operation, low construction cost and prevention of oil theft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the drawings.

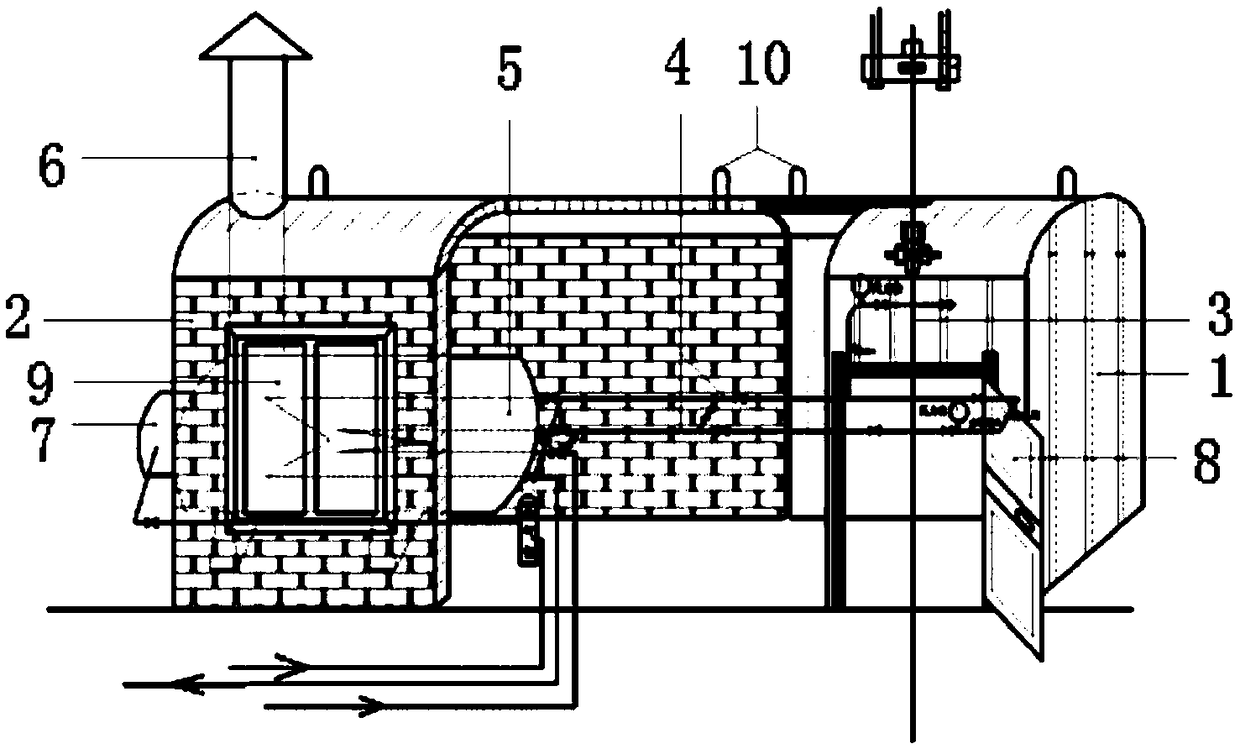

[0011] The heat preservation room for heavy oil wells provided by the present invention includes: a brick-concrete arched housing body 2 is built outside the heating furnace 5, the heating furnace flame head 7 is arranged outside the brick-concrete arched housing body 2, and the heating furnace chimney 6 extends Brick-concrete arch covering the roof of the building body 2, outside the heavy oil well Christmas tree 3, the steel frame colored board movable housing body 1, and the steel frame colored board movable housing body 1 directly in front of the heavy oil well Christmas tree 3 is installed. Door 8, the roof of the steel frame colored board movable house body 1 is provided with a passage for the polished rod and polished rod sealer to pass, the steel frame colored board movable house body 1 and the brick-concrete arch cover house body 2 are butt sealed, and the steel frame colore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com