Water seal sleeve device

A water-envelope and annular sealing technology, which is applied to the sealing device of the engine, engine components, machines/engines, etc., can solve problems such as material fatigue damage, and achieve the effect of increasing the contact area, improving the flow state and ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

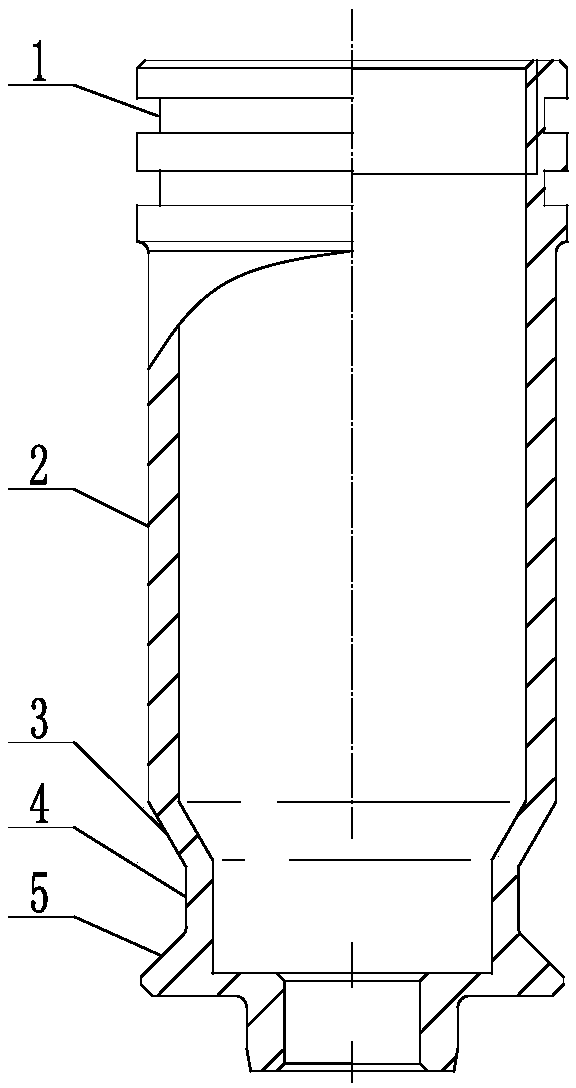

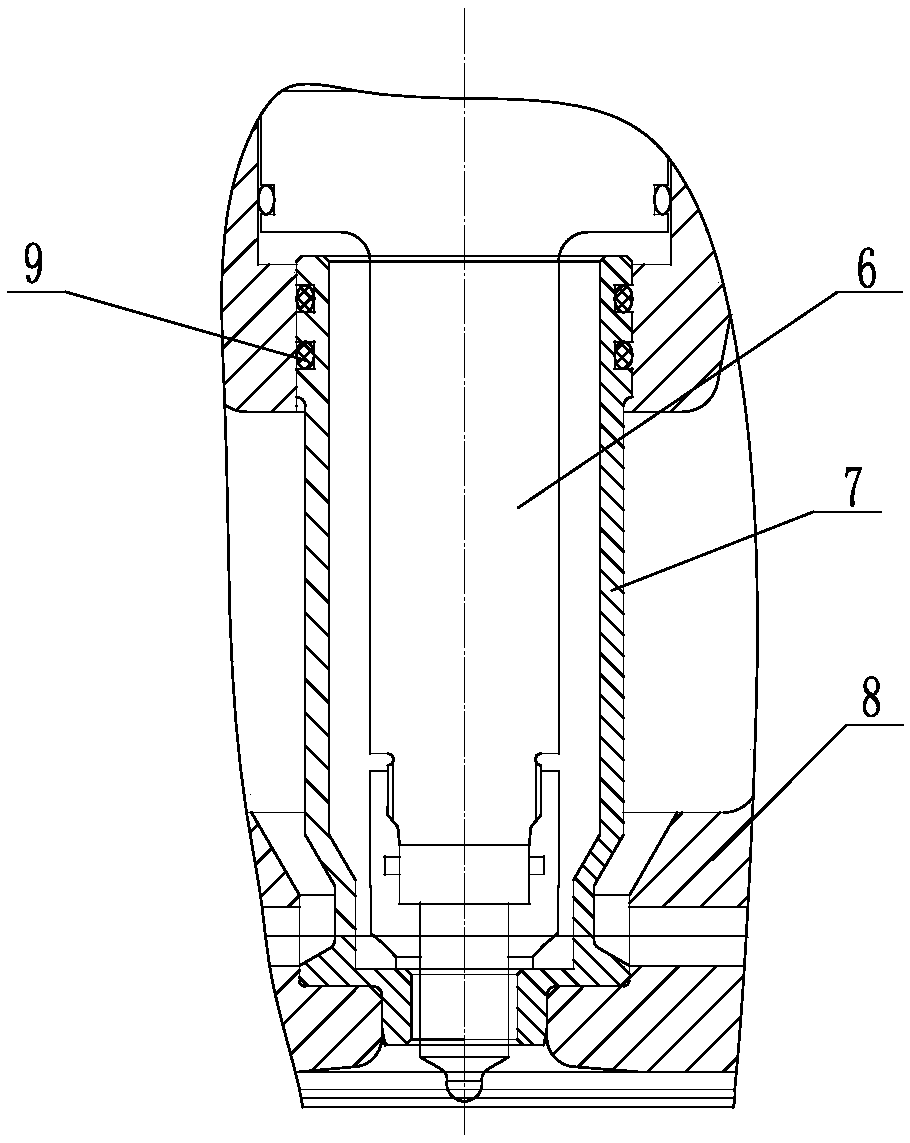

[0018] like Figure 1 ~ Figure 2 As shown, the water seal device of the present invention includes a water seal body 7, and the water seal body 7 includes three sections of cylindrical cavities arranged up and down, which are respectively the first cylindrical cavity body 2 and the second cylindrical cavity body 4 and the third cylindrical cavity body, a cylindrical cavity body 3 with a variable diameter section is arranged between the first cylindrical cavity body 2 and the second cylindrical cavity body 4, an annular sealing groove 1 is arranged on the upper part of the first cylindrical cavity body 2, and the second A tapered boss 5 is arranged between the second cylindrical cavity body and the third cylindrical cavity body. The diameter of the bottom of the tapered boss 5 is larger than the diameter of the top. The water seal body 7 adopts 2cr13 stainless steel. A hi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap