Pump body component, variable-capacity compressor and air regulation system

A technology for compressors and components, applied in pump components, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve the problems of pulsation, small sliding vane groove volume, and excessive pressure at the end of the vane, etc. Achieve the effect of improving reliability and reducing operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

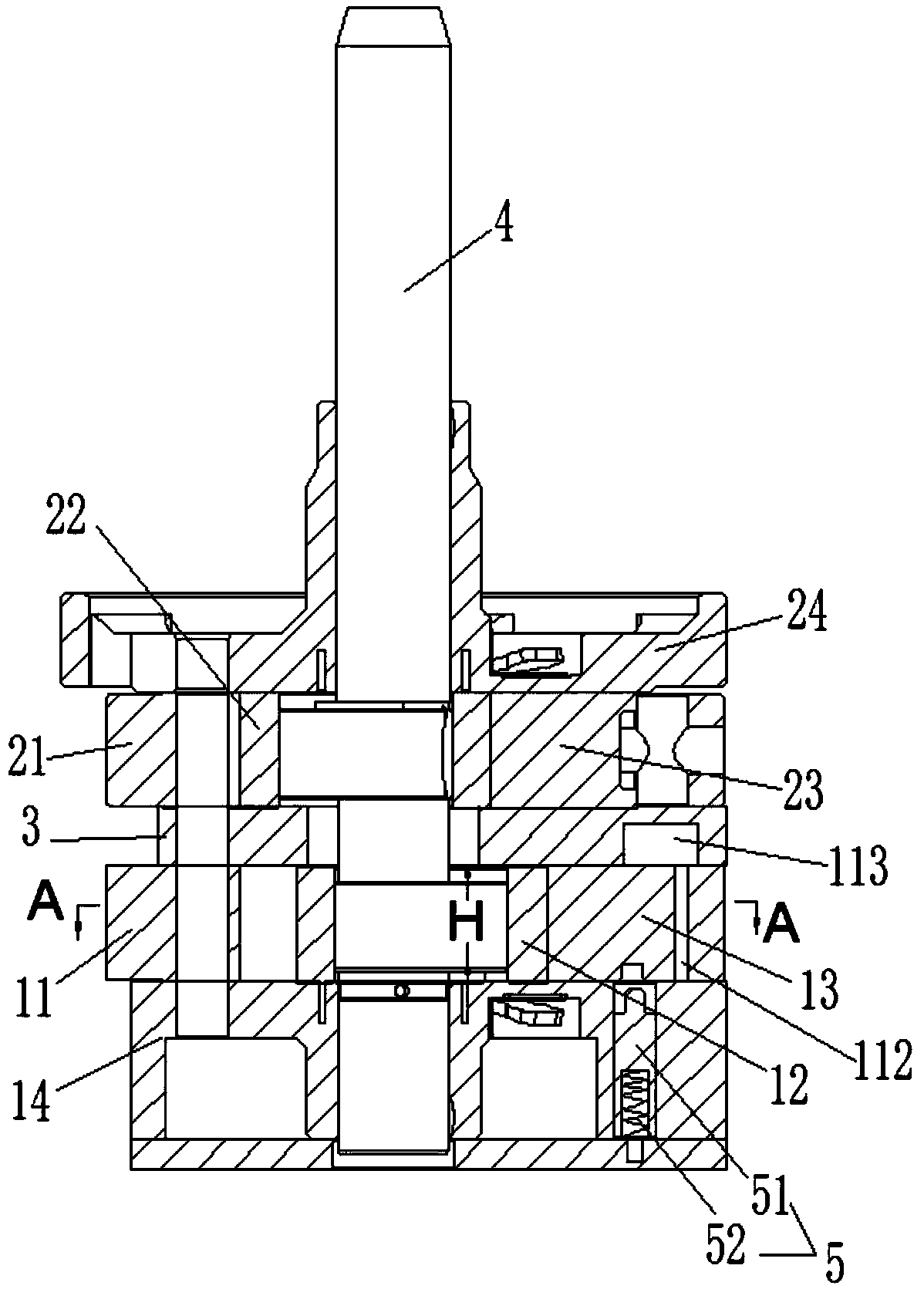

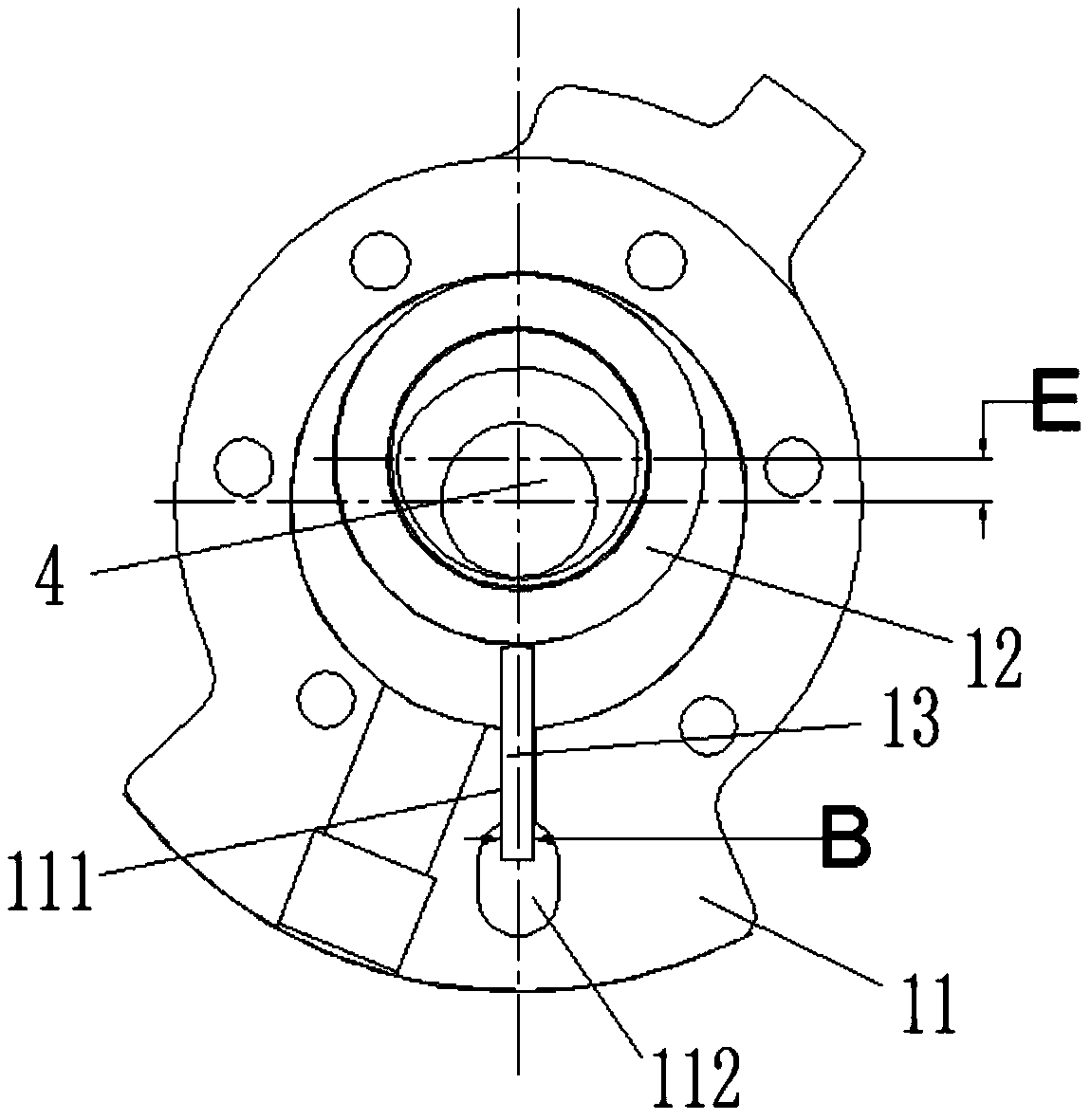

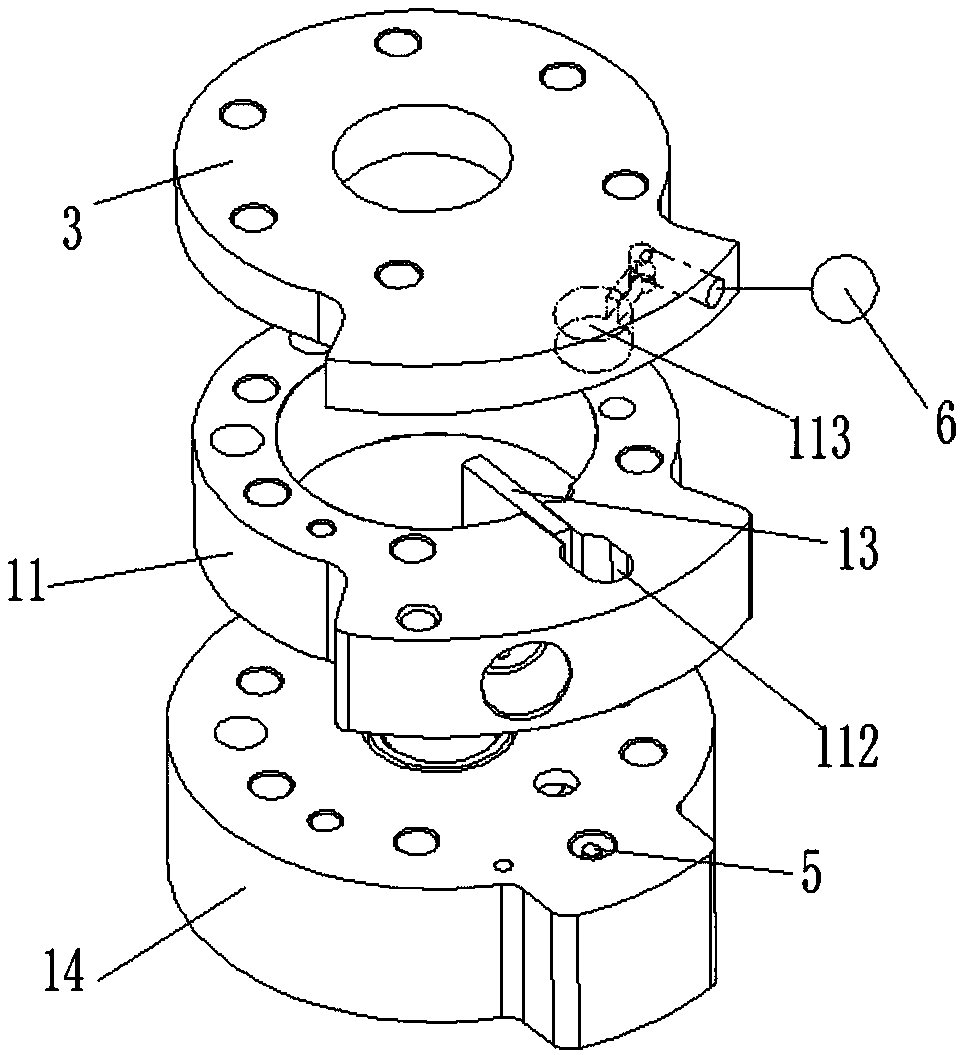

[0023] see in conjunction Figure 1 to Figure 6 As shown, according to an embodiment of the present invention, a pump body assembly is provided, including a first compression part 1, a second compression part 2, and a partition 3, and the first compression part 1 and the second compression part 2 pass through The rotating shafts 4 are stacked together and share the partition plate 3. The first compression part 1 includes a first cylinder 11, a first roller 12, a first sliding plate 13, and a first bearing 14. The first roller 12 is eccentrically installed on the rotating shaft 4 and located in the first cylinder 11, the outer circumference of the first roller 12, the inner wall of the first cylinder 11, the first bearing 14 and the partition 3 together form a first working chamber, In the same way, the second compression part 2 includes a second cylinder 21, a second roller 22, a second sliding plate 23, and a second bearing 24, and the second roller 22 is eccentrically instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com