Tube plugging device for electric generator hydrogen-cooled device heat exchange tube

A technology of hydrogen cooler and heat exchange tube is applied in the field of heat exchange tube plugging device of hydrogen cooler of generator. The effect of blocking and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

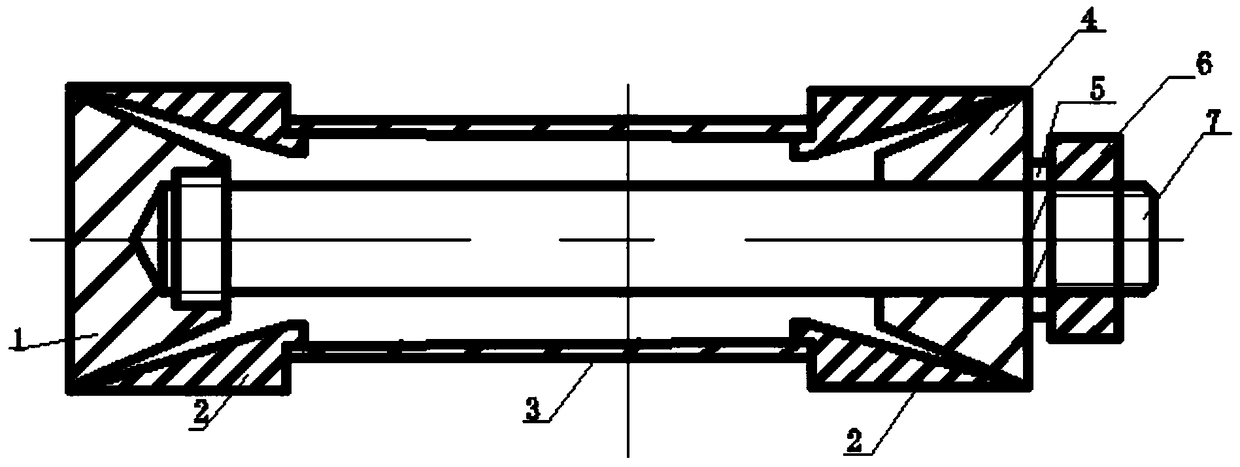

[0013] The present invention will be described in detail below in conjunction with accompanying drawing, as figure 1 As shown: the pipe plugging device for the heat exchange tube of the generator hydrogen cooler of the present invention includes a blind hole wedge head 1, a tightening screw 7, a through hole wedge head 4, a sealing gasket 5, a fastening nut 6, a sealing sleeve 2 and a liner Sleeve 3, one end of the tightening screw is threadedly connected with the blind hole opened in the blind hole wedge head, and the other end is threaded with the fastening nut after passing through the through hole wedge head and the sealing gasket in turn, and the blind hole wedge head and the through hole Sealing sleeves are sheathed on the outside of the wedge-shaped head, and the bushing is located between the two sealing sleeves. The bushing is made of stainless steel, and according to the overall length of the plugging device, bushings of different lengths are cut to meet the use requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com