Cable temperature and humidity monitoring sensing device and monitoring system thereof

A technology of temperature and humidity sensor and sensing device, applied in the direction of measuring device, measuring device casing, instrument, etc., can solve the problem of difficult replacement, and achieve the effect of improving efficiency, flexible size, and accurate selection of points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

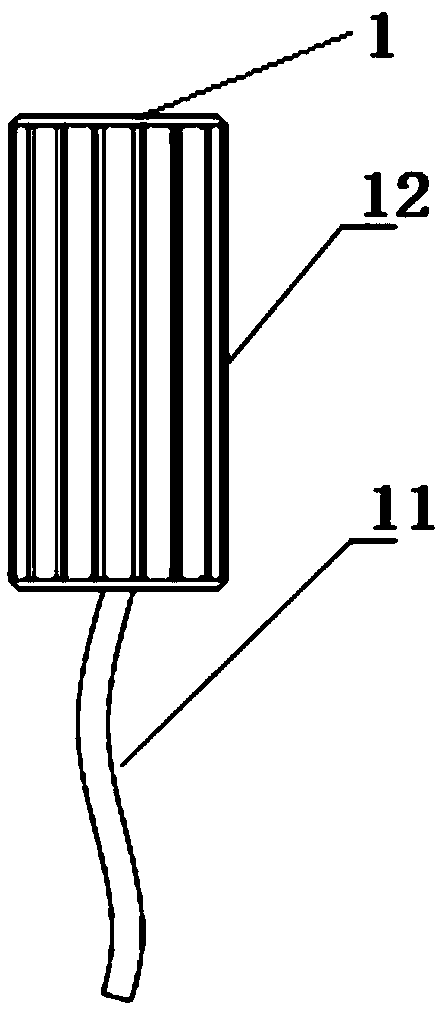

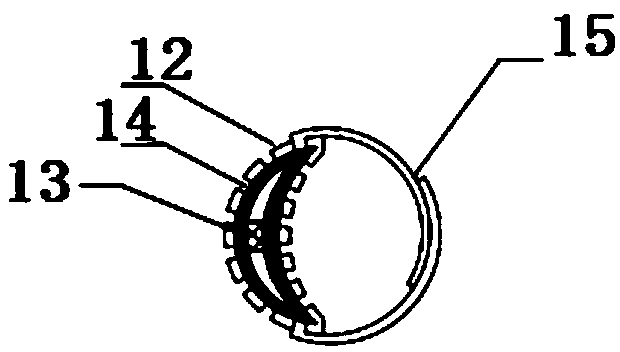

[0025] like Figure 1-Figure 5 As shown, a cable temperature and humidity monitoring sensor device includes a first temperature and humidity monitoring sensor device 1 and a second temperature and humidity monitoring sensor device 2, the first temperature and humidity monitoring sensor device 1 is installed on the main cable cable Inside, the second temperature and humidity monitoring sensing device 2 is installed in the cable anchor room area, and the first temperature and humidity monitoring sensing device 1 includes a first lead terminal 11, a first sensing protective cover 12, a first temperature and humidity sensor 13, The first dustproof cap 14, the automatic adjustment hoop 15, the first temperature and humidity sensor 13 is arranged in the first dustproof cap 14, and the first sensing protective cover 12 is arranged outside the first dustproof cap 14, The automatic adjustment hoop 15 hoops the first sensing protective cover 12 on the cable, and the first lead terminal ...

Embodiment 2

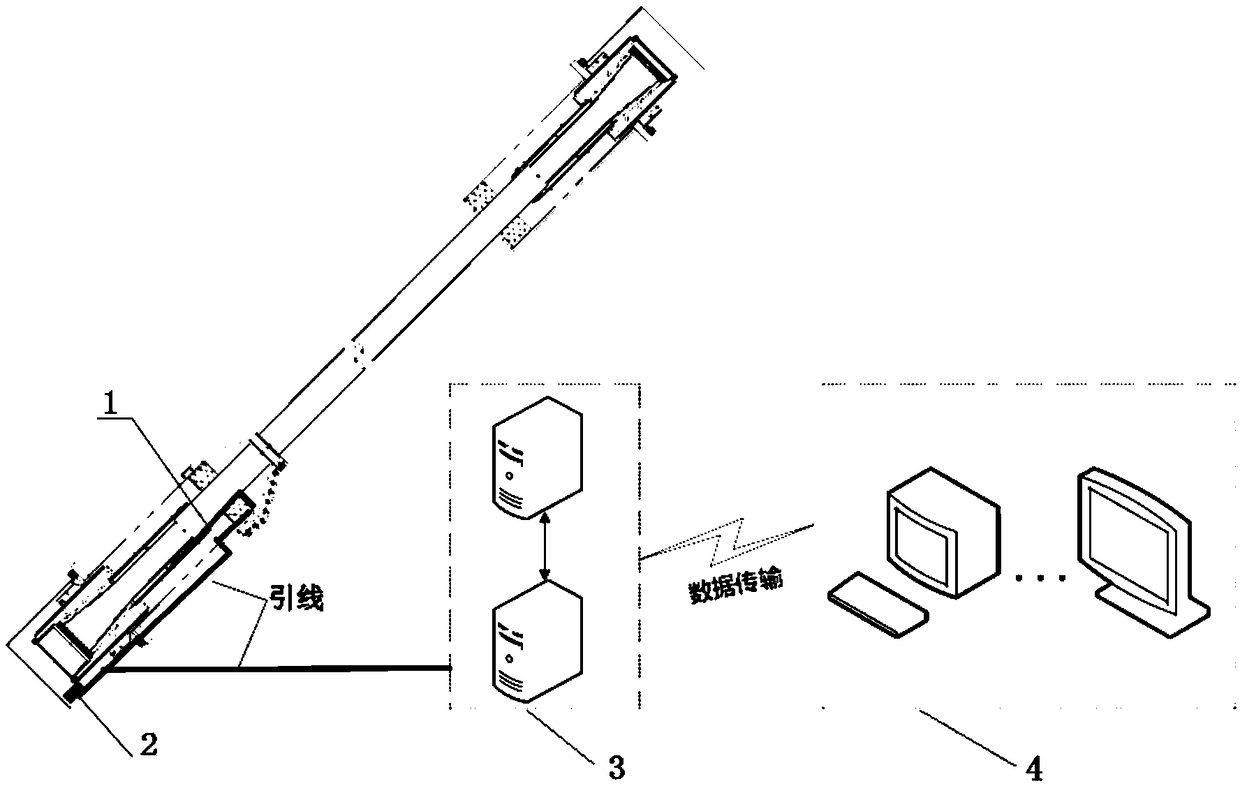

[0029] like figure 1 , Figure 7-Figure 8 As shown, a cable temperature and humidity monitoring system includes a first temperature and humidity monitoring sensor device 1 installed in the main cable cable, a second temperature and humidity monitoring sensor device 2 installed in the anchor room area of the cable, and the ground Data processing center 3 and monitoring control center 4, described ground data processing center 3 comprises data processing module 31 and data preprocessing module 32, and described data preprocessing module 32 connects with first lead terminal 11 and second lead terminal 21 respectively The first temperature and humidity monitoring sensing device 1 and the second temperature and humidity monitoring sensing device 2 are connected and receive the temperature and humidity monitoring value, and the data processing module 31 is used to store the data of the data preprocessing module 32 and send it to Monitoring and control center 4; the monitoring and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com