Water injection type multi-module push plate wave maker

A wave-making machine and multi-module technology, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of insufficient power of servo motors, limited application range, and easy generation of clutter, etc., to achieve shortened wave-making cycle, solve the power shortage, and improve the effect of wave-making accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

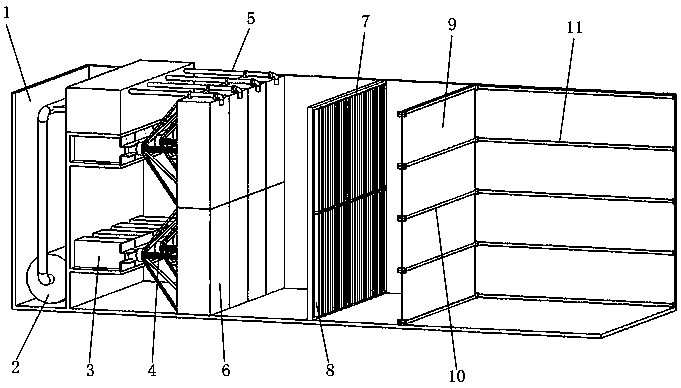

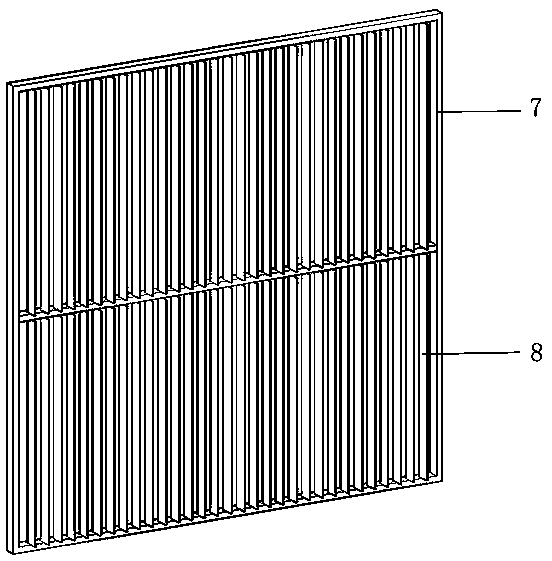

[0013] Such as figure 1 As shown, a water-injection multi-module push-plate wave maker consists of a water tank (1), a servo motor (3), a wave-making plate (6), a water injection pipe (5), a filter net (7), and a wave-making film (9) Composition; the water tank (1) and the filter net (7) and the wave-making membrane (9) form a closed water area; the servo motor (3) drives the structural support and the wave-making plate through the drive rod (4) (6) Do reciprocating motions to form initial waves; the wave-making plate (6) is composed of eight modules, driven by different servo motors (3) to produce waves of different frequencies; the water injection pipe (5 ) is controlled by a computer, injecting pre-calculated water along the wave-making plate (6); the filter net (7) diverts the obliquely propagating waves through the action of the deflector (8); the wave-making Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com