Static pressure testing device for unmanned plane oil gas damper

A technology for static pressure testing and shock absorbers, applied in the field of static pressure testing devices for unmanned aerial vehicle oil and gas shock absorbers, can solve the problems of unfavorable use cost and convenience for delivery to users, prone to human misjudgment, unfavorable maintenance work, etc. , to achieve the effect of facilitating field operation, efficient and fast testing, and simple testing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

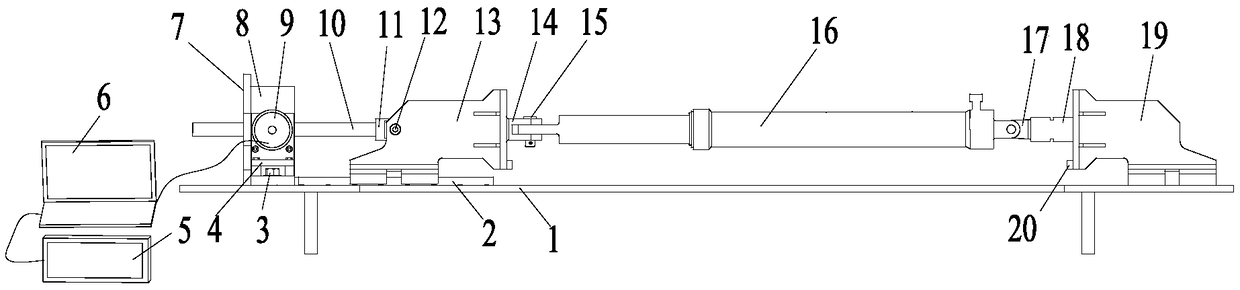

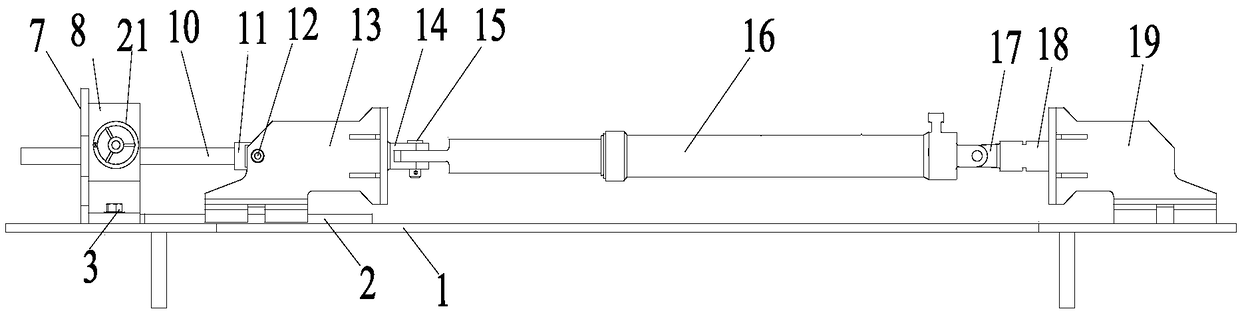

[0022] This embodiment is a static pressure testing device for an oil-gas shock absorber of an unmanned aerial vehicle.

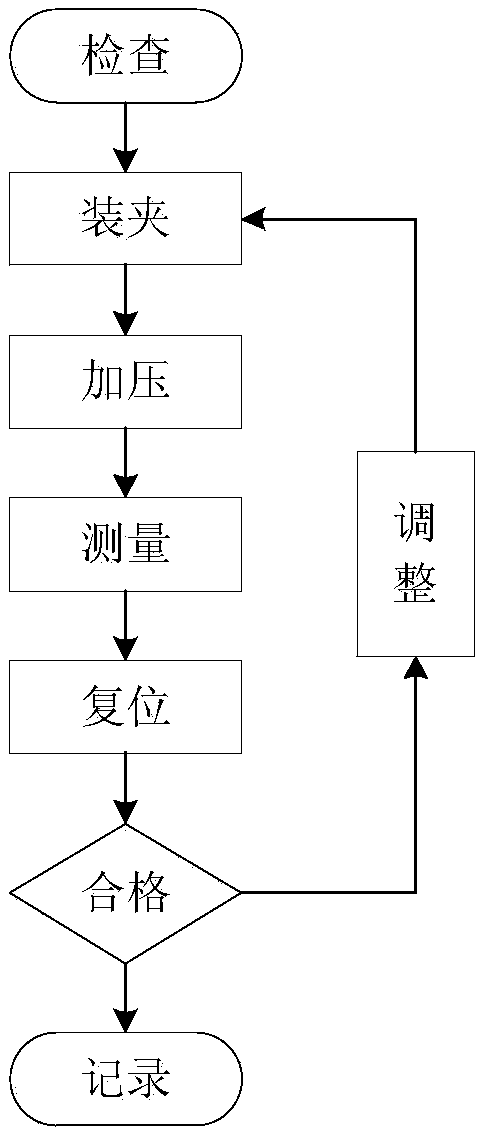

[0023] refer to Figure 1 ~ Figure 3 , the present embodiment UAV oil-gas shock absorber static pressure test device, by platform support 1, guide rail 2, bolt 3, digital display instrument 5, control computer 6, first connector 11, pressure sensor 12, first mount 13. Joint 14, connecting pin 15, shock absorber 16, second connecting piece 17, tension and pressure sensor 18, second mounting seat 19, digital display displacement sensor 20, hand wheel 21 and lead screw transmission platform; wherein, the wire The bar transmission platform includes a motor mounting plate 4, an installation vertical plate 7, a screw mounting seat 8, a servo motor 9 and a leading screw 10, the screw transmission platform is fixedly connected to the upper side end of the platform support 1 by bolts 3, and the first mounting seat 13 Located inside the lead screw drive platform, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com