Mold number coding online imaging apparatus, mold number coding online imaging system and mold number coding online detection method

An imaging device and detection method technology, applied in measuring devices, character and pattern recognition, and material analysis through optical means, can solve problems such as poor production flexibility, high coaxiality requirements, and imaging asymmetric distortion, and achieve Good compatibility and versatility, good sensitivity and contrast, and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides an online imaging device for mold number coding, which is used to detect the mold number coding of a bottle, which includes a light source and a camera, and the light source is arranged below the bottom of the bottle to be tested, facing the bottle to be tested The direction of the bottom of the bottle is irradiated; the camera is arranged above the mouth of the bottle to be tested, and shoots in the direction of the mouth of the bottle to be tested.

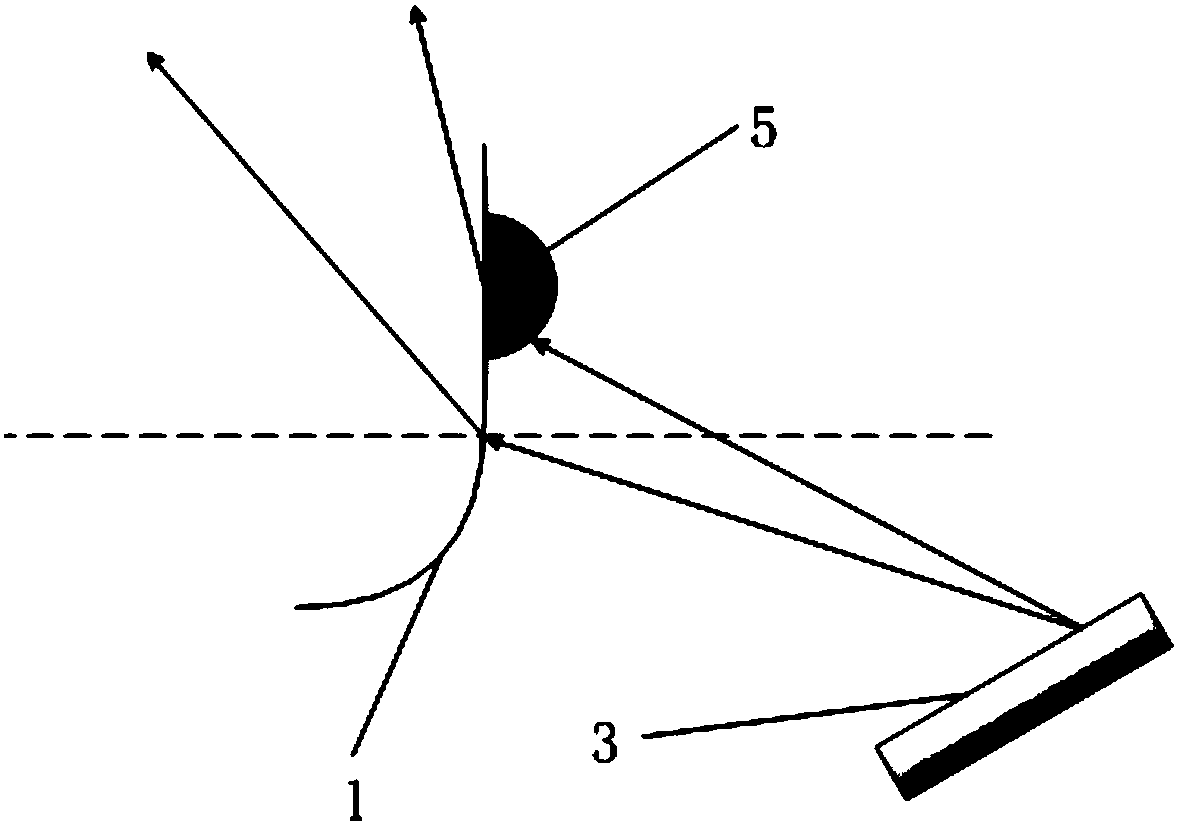

[0039] Set the light source below the bottom of the bottle to be tested, and irradiate toward the bottom of the bottle to be tested. The camera is placed above the bottle to be tested to clearly observe the image of the bump coding area on the bottom of the bottle. The impact on the refraction of the light path can directly project the light from the bottom light source into the camera, while other smooth areas on the side of the bottle cannot converge the light to the bottle mouth, and the black b...

Embodiment 2

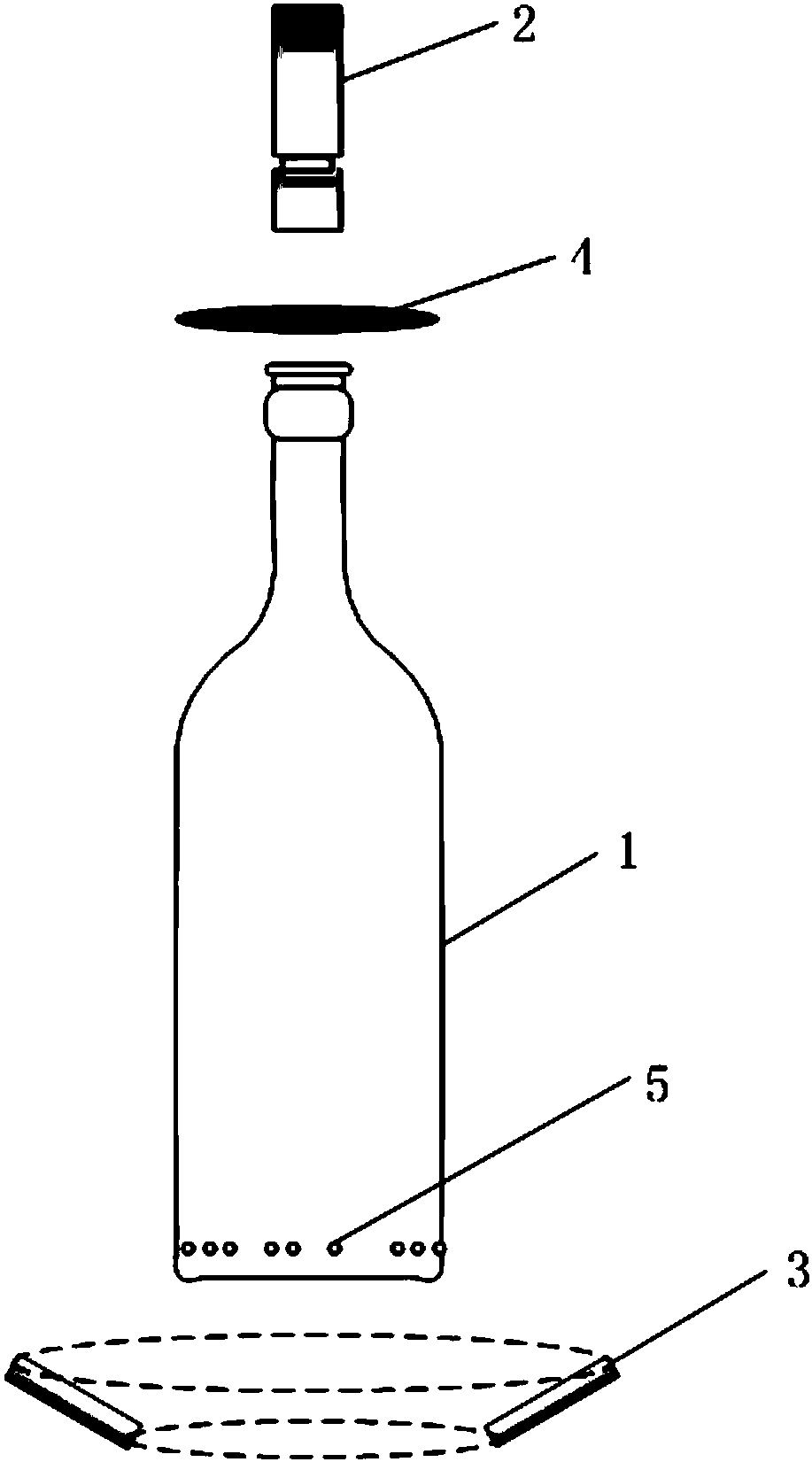

[0043] Such as figure 1As shown, the mold number code online imaging device provided in this embodiment is used to detect the mold number code of the bottle body 1, and it includes a light source 3 and a camera 2, and the light source 3 is arranged below the bottom of the bottle body to be tested. Irradiating toward the bottom of the bottle to be tested; the camera 2 is set above the mouth of the bottle to be tested, and shoots in the direction of the mouth of the bottle to be tested.

[0044] The imaging device can also include a convex lens 4, which is arranged at a position between the camera 2 and the mouth of the bottle body 1. Preferably, the light source 3, the bottle body 1, the convex lens 4 and the camera 2 They are sequentially arranged coaxially along the light emitting direction of the light source 3 . The convex lens 4 can be a single convex lens or a combined convex lens, wherein the combined convex lens can include a plano-convex lens and a double-sided convex...

Embodiment 3

[0049] Based on the mold number code online detection system described in the second embodiment above, one of the implementations of the mold number code online detection method provided by this embodiment is as follows: Figure 5 shown, which includes:

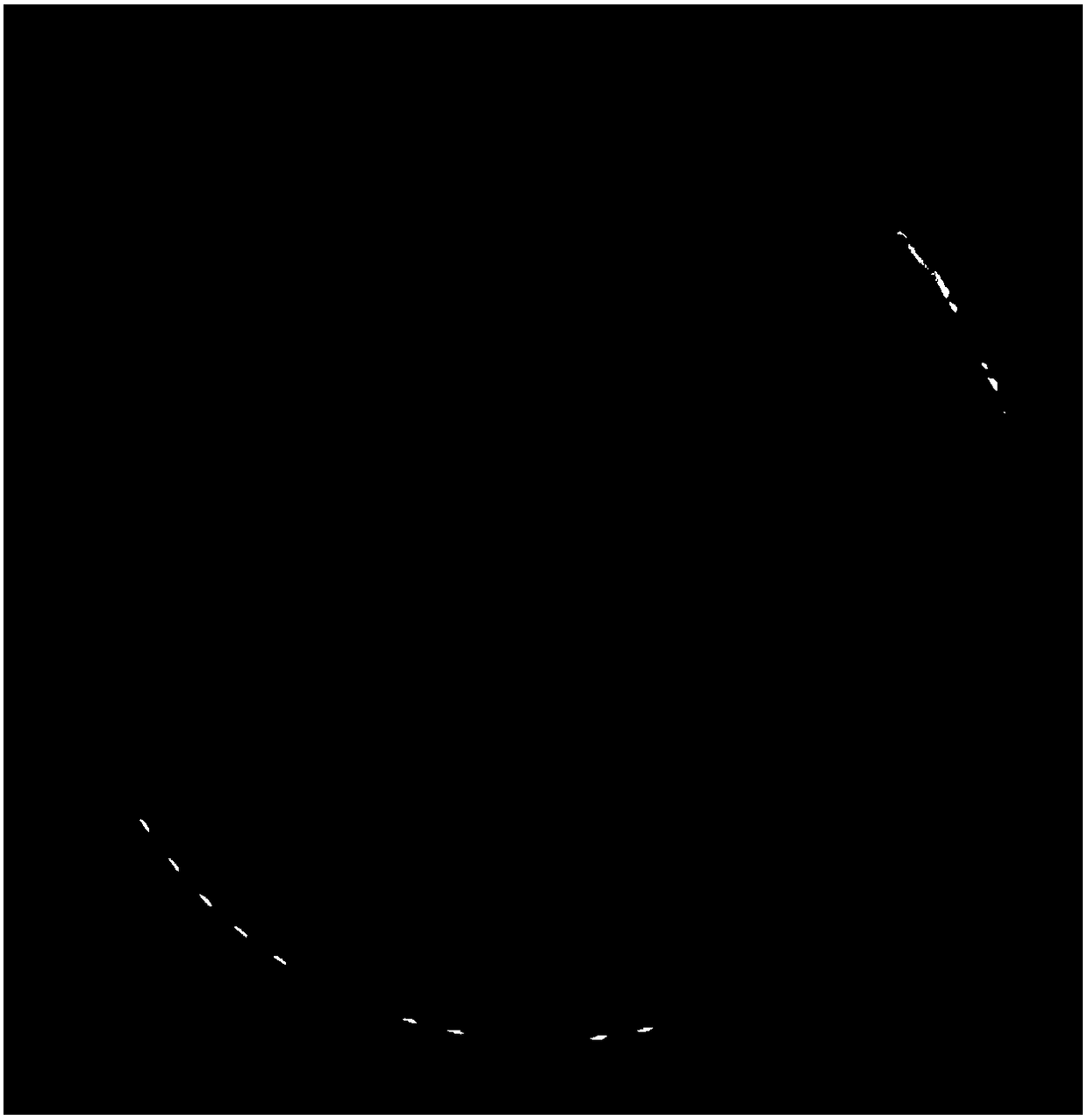

[0050] S1: Obtain the collected image of the bottom of the bottle;

[0051] S2: performing a binarization operation on the bottle bottom image, extracting a bottle bottom region image, and filtering the bottle bottom region image to obtain a bottle bottom outer contour region image;

[0052] S3: expand the area where the bumps are located in the image of the outer contour area of the bottle bottom, and obtain the expanded image of the bump area;

[0053] S4: Filtering the expanded bump area image, and identifying the mold number according to the bumps on the filtered bump area image.

[0054] In S2, first, binarize the collected image of the bottom of the bottle. Methods such as local binarization, fixed threshold binariz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com