Automatic door opening and closing structure for high-voltage cabinet

A technology for automatic opening and closing of doors and high-voltage cabinets, which is applied to power control mechanisms, substation/switch layout details, door/window accessories, etc., which can solve problems such as electric shock death, cabinets with points, and high cost, so as to avoid high costs and provide convenience The effect of the overhaul process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

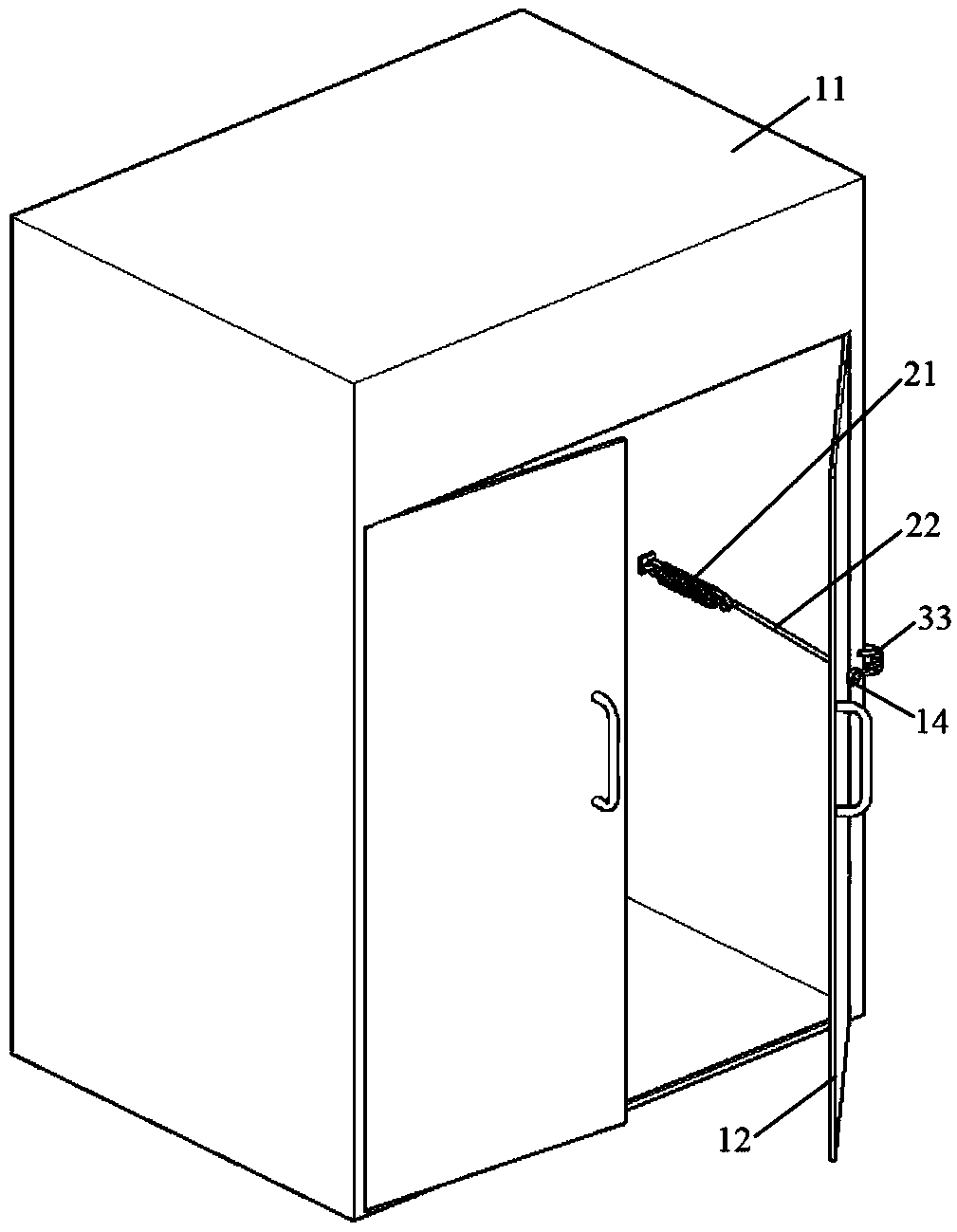

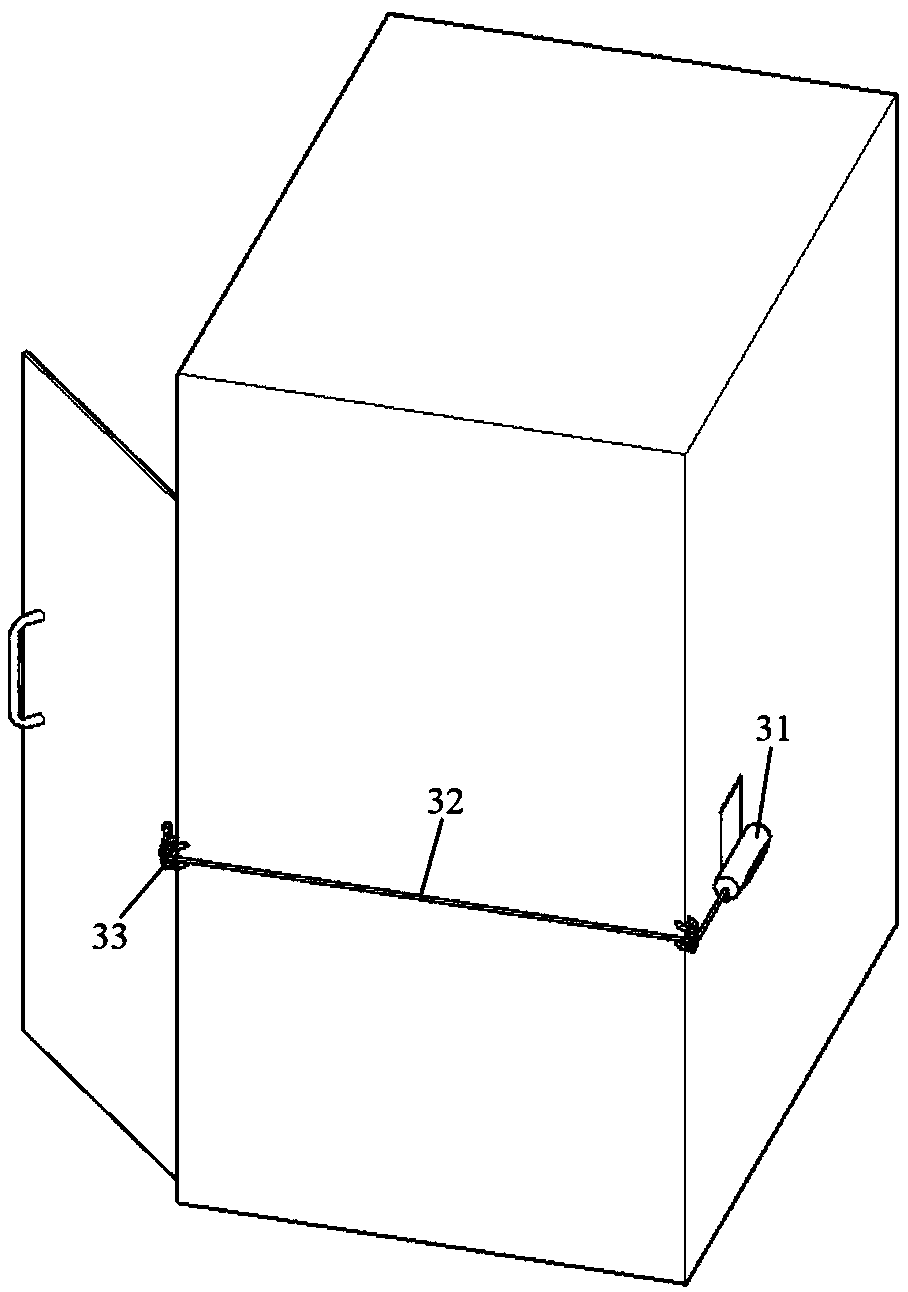

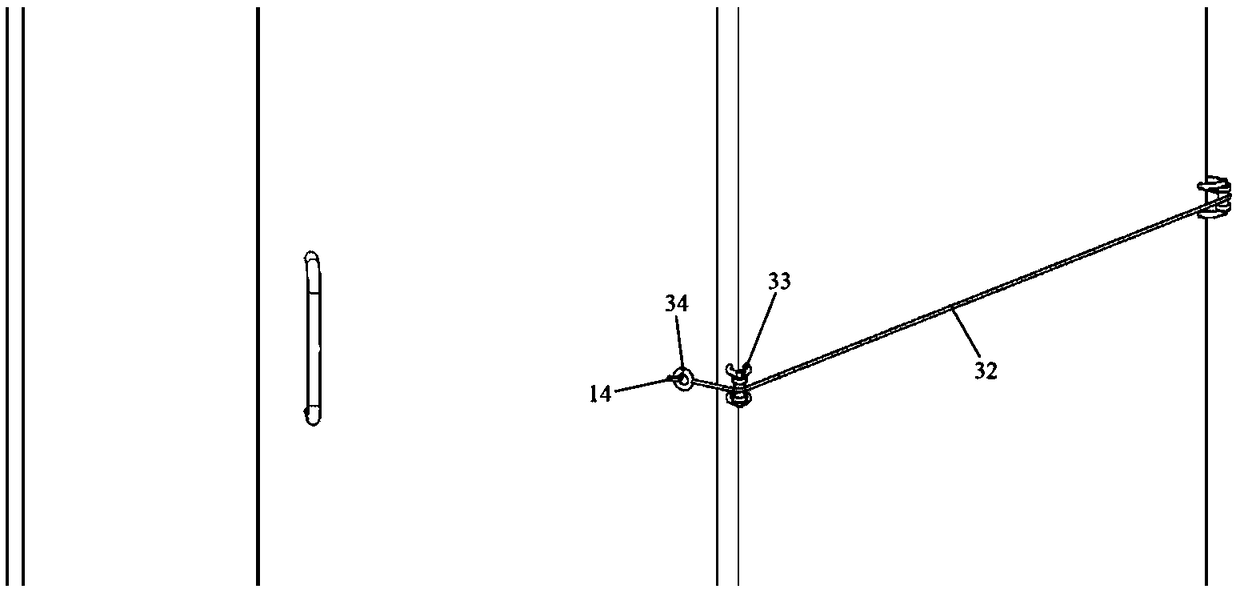

[0020] Such as figure 1 A high-voltage cabinet automatic door switch structure shown includes a cabinet body 11 and a door panel 12 that constitute a closed cavity of the high-voltage cabinet; an inner door knocker 13 is fixed on the side of the door panel 12 inside the cavity, and an outer door knocker is fixed on the side outside the cavity 14. A spring 21 is fixed on the inner wall of the cabinet body 11, and the spring 21 pulls the inner door knocker 13 tightly through the inner cable 22; a coil 35 is fixed on the back of the cabinet body 11, and the coil 35 is inner with a magnetic block 36, and the magnetic block 36 The end is fixed on the rear end of the outer cable 32, the corner position of the outer wall of the cabinet body 11 is fixed with a pulley block 33, the outer cable 32 is limited to the pulley block 33, the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com