Current balanced flat copper wire wave winding armature winding

An armature winding and current balance technology, applied in the shape/style/structure of the winding conductor, etc., can solve the problems of increased winding temperature, unbalanced current of the three branches, and damage to the motor insulation system due to the inner temperature, so as to improve the overall performance, the effect of improving electrical performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

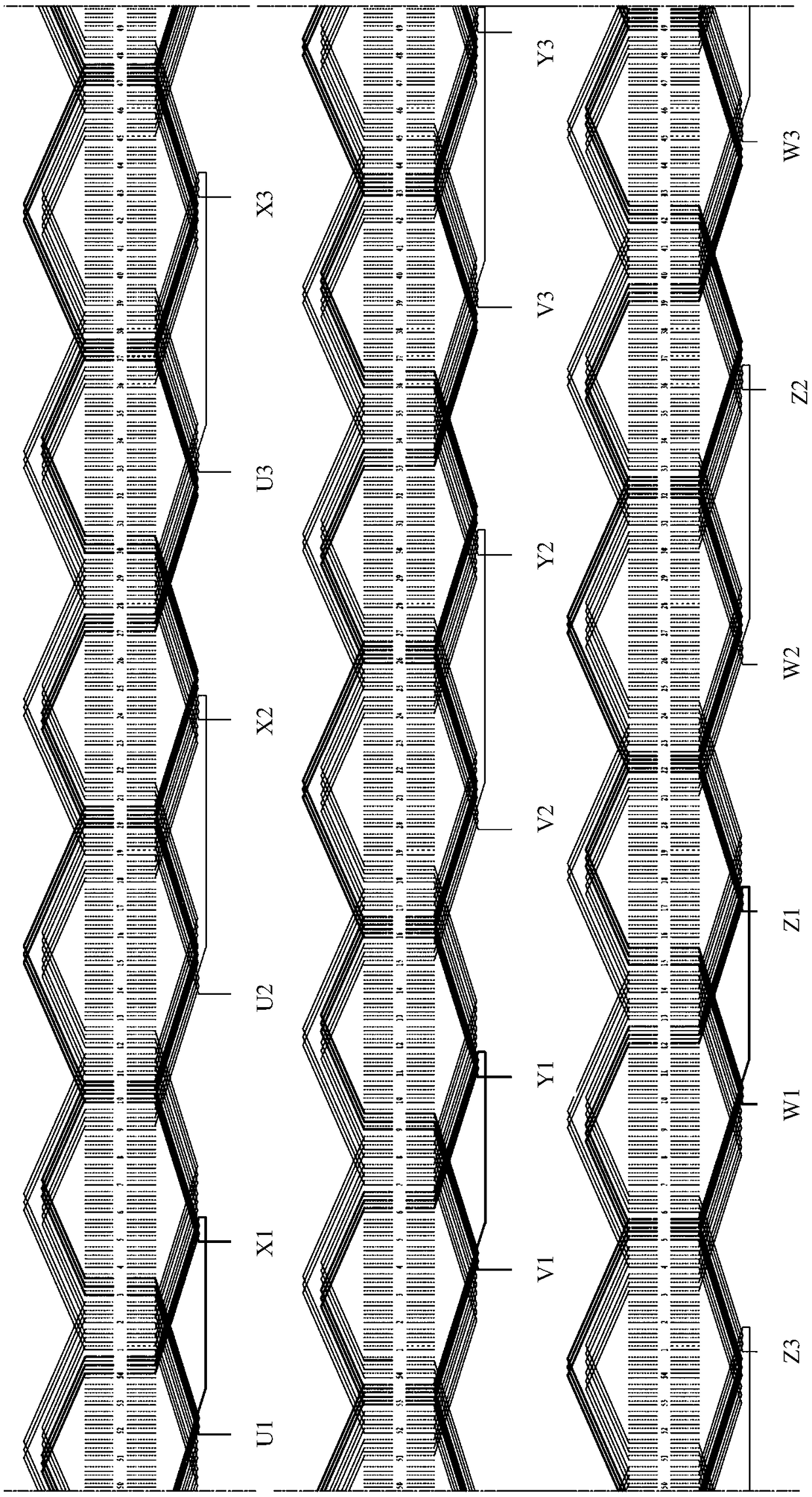

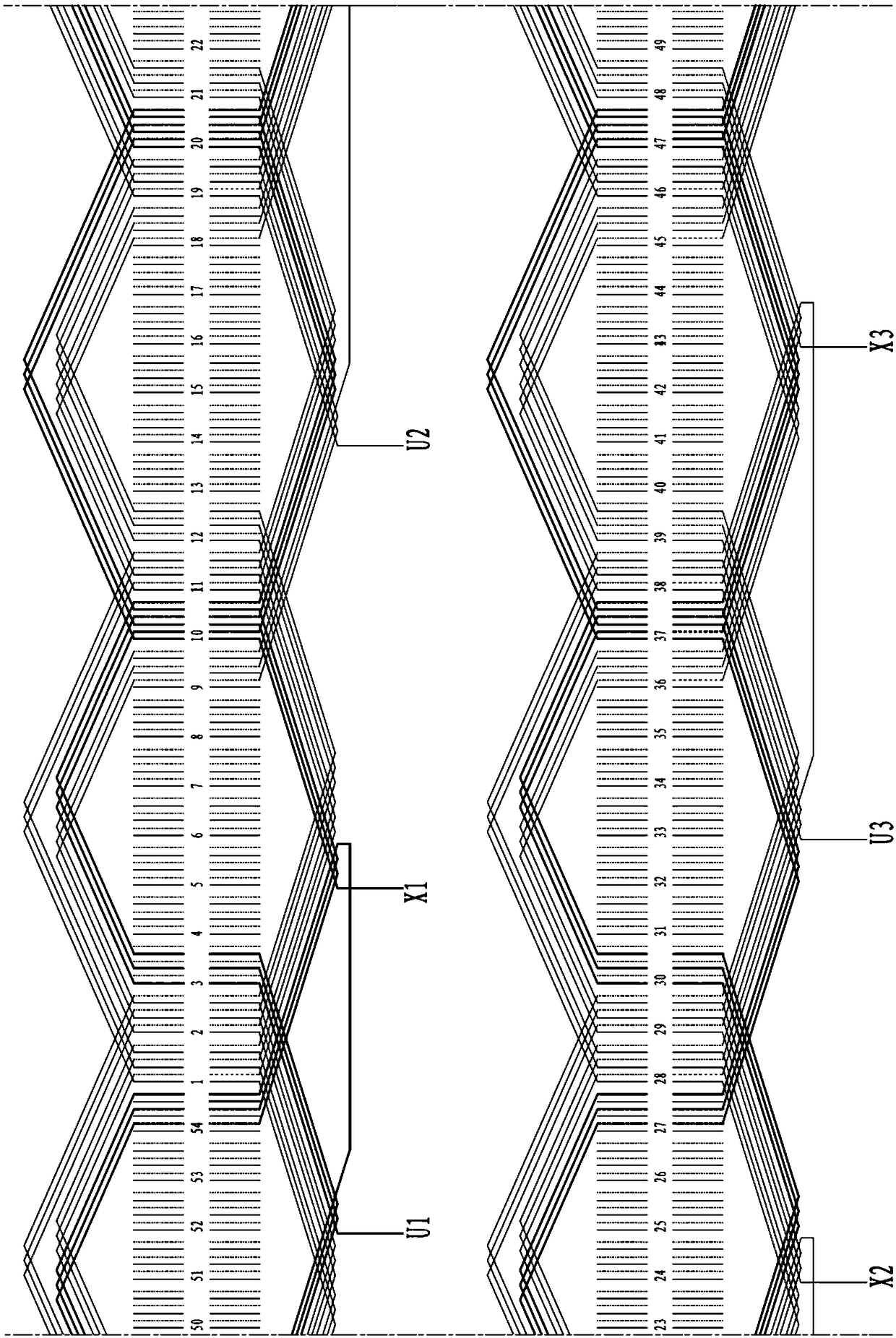

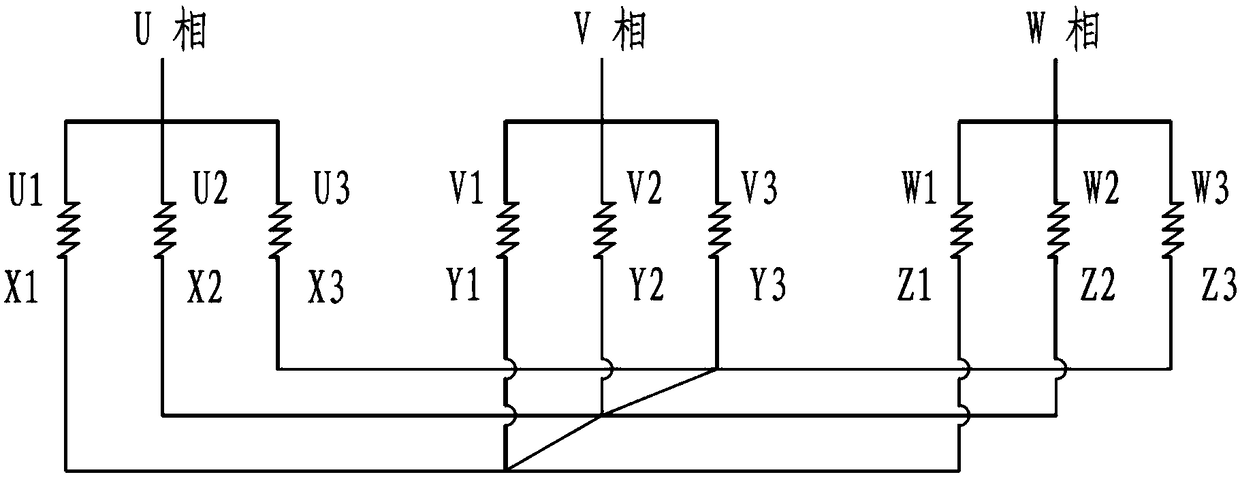

[0019] The flat copper wire wave winding armature winding of the present invention is a six-layer wave winding structure, and the winding lead-out terminals U1, U2, U3, V1, V2, V3, W1, W2, W3, X1, X2, X3, Y1 , Y2, Y3, Z1, Z2, and Z3 subscript numbers 1, 2, and 3 correspond to star point branch 1, star point branch 2, and star point branch 3 respectively.

[0020] This flat copper wire wave winding does not adopt prior art scheme (1, 2 layers constitute a branch (inner layer), 3, 4 layers are a branch (middle layer), 5, 6 layers are another branch (outer layer) Layer), three branches connected in parallel), each phase winding also has three branches, but each branch is composed of 1, 2, 3, 4, 5, 6 layers of flat copper wires.

[0021] This measure is applicable to the number of conductor layers per slot N=6, and the parallel branch is 3, all kinds of stator slot numbers (including 36, 48, 54, 60, 72, 84, 90 slots, etc.) are applicable, and the winding pitch is Suitable for sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com