A generator rotor coil water circuit pickling device

A generator rotor and pickling device technology, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve the problems of magnetic field performance and motor efficiency decline, doping, etc., to improve the pickling effect, Guarantee normal performance and avoid the effect of corrosive damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

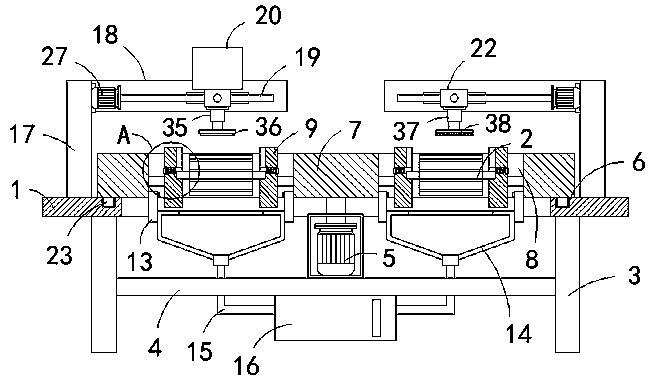

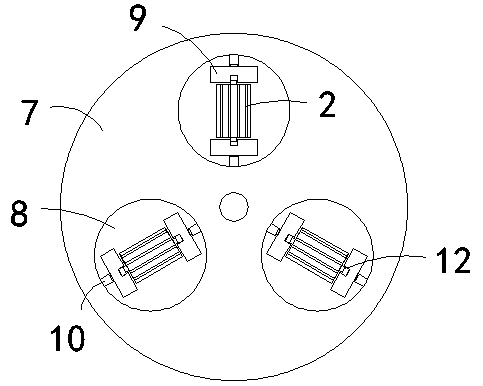

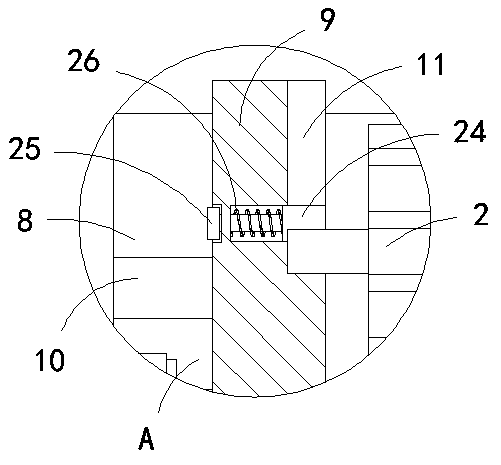

[0028] Such as Figure 1-5 As shown, a generator rotor coil water circuit pickling device includes an annular workbench 1 and a generator rotor 2, and a plurality of vertical support columns 3 are fixedly connected to the bottom wall of the annular workbench 1, and a plurality of support columns 3 The same horizontal plate 4 is fixedly connected between the columns 3, the first motor 5 is fixedly connected to the center of the top wall of the horizontal plate 4, and the ring slide rail 6 is provided on the top wall of the ring worktable 1, and the ring slide rail 6 rotates inside Connected with the same round table 7, the drive shaft of the first motor 5 is fixedly connected on the bottom wall of the round table 7, and the top wall of the round table 7 is provided with three circular through holes 8 connected up and down, specifically, three circular thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com