Paint-spraying device equipped with cover type structure and used for electromechanical fan blades

A fan fan and electromechanical technology, applied in the field of electromechanical fan blade paint spraying devices, can solve the problems of easy touch and scratch, poor fan blade paint uniformity, poor applicability, etc., to avoid spray leakage, ensure paint uniformity, and be widely used Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

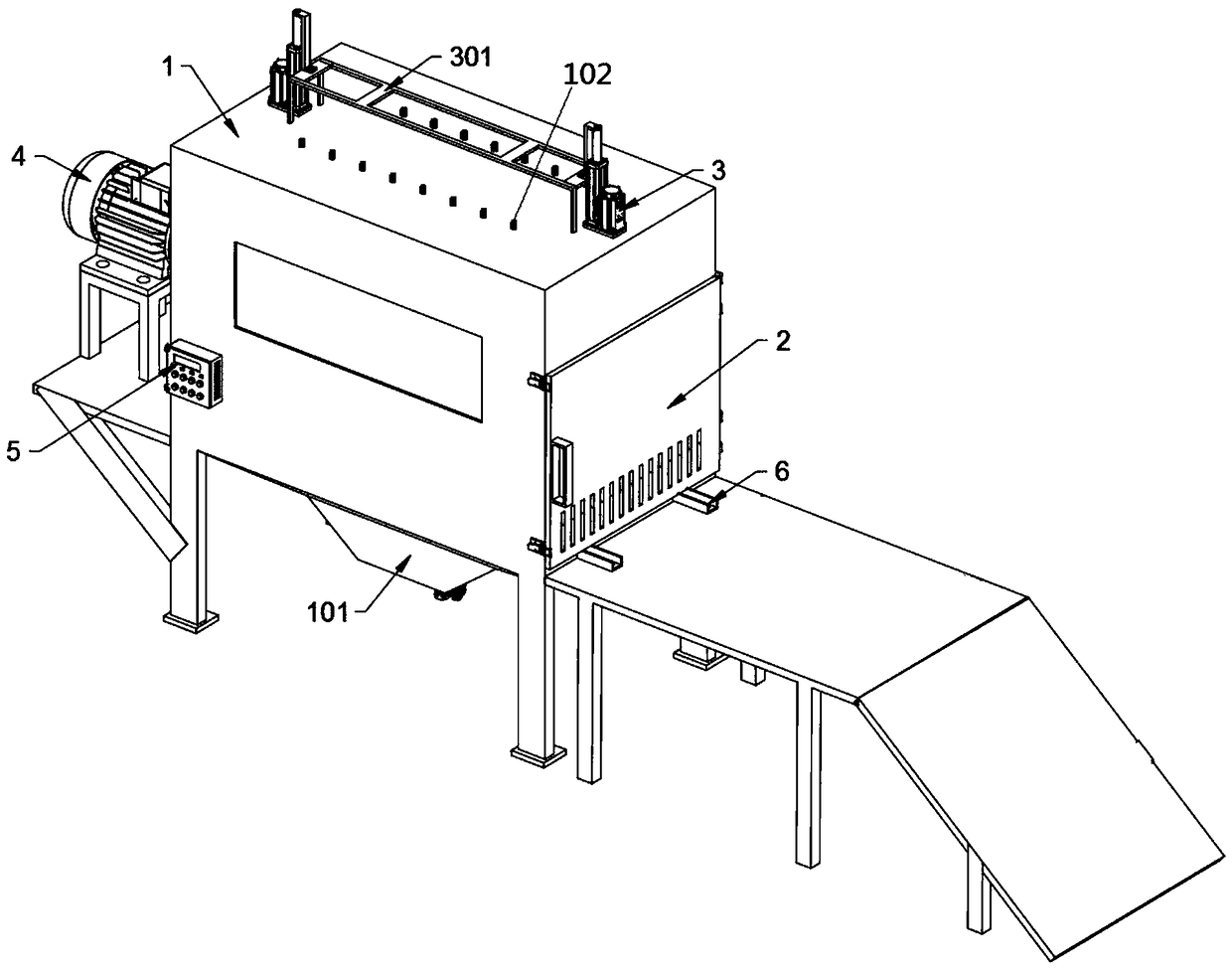

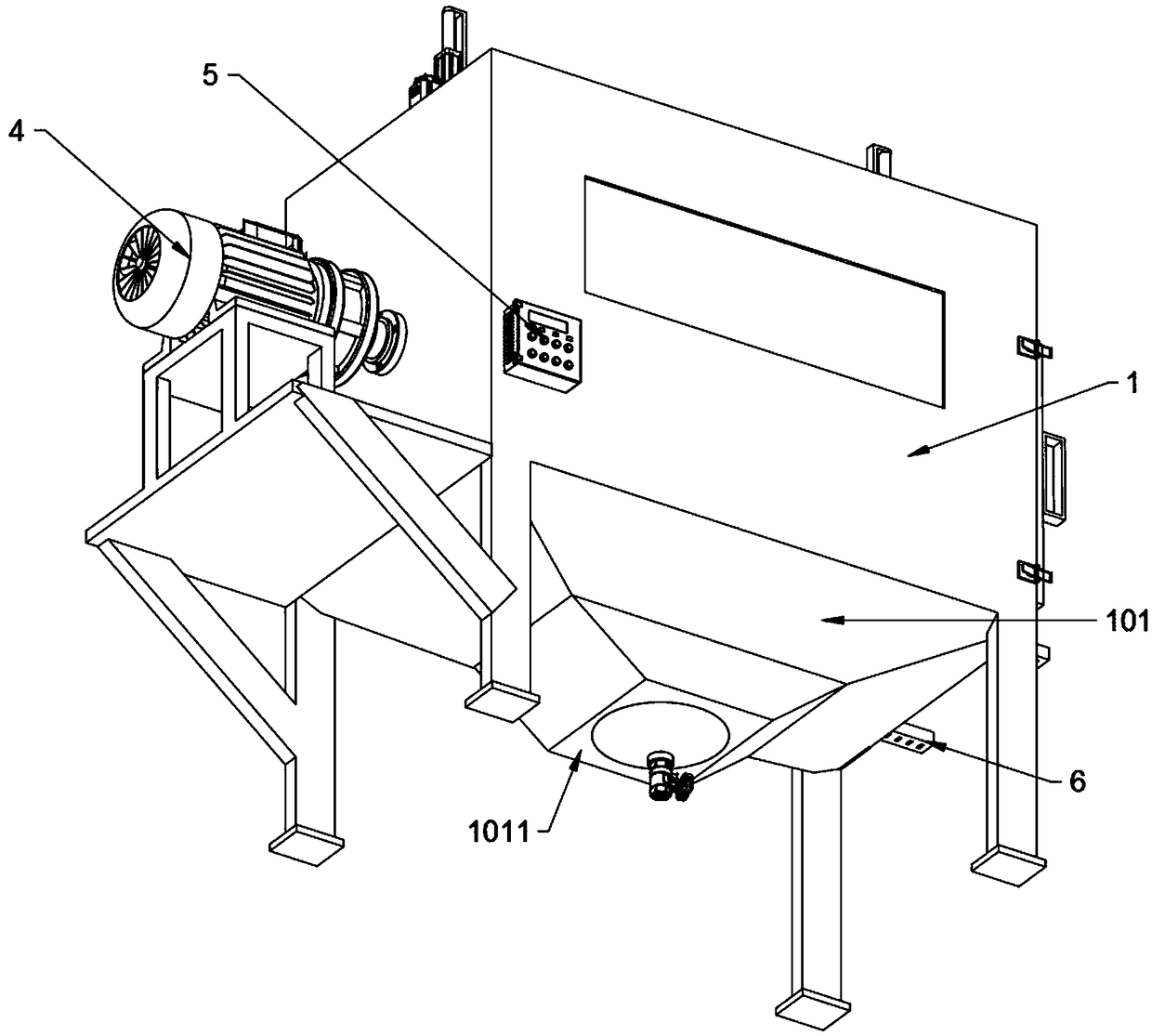

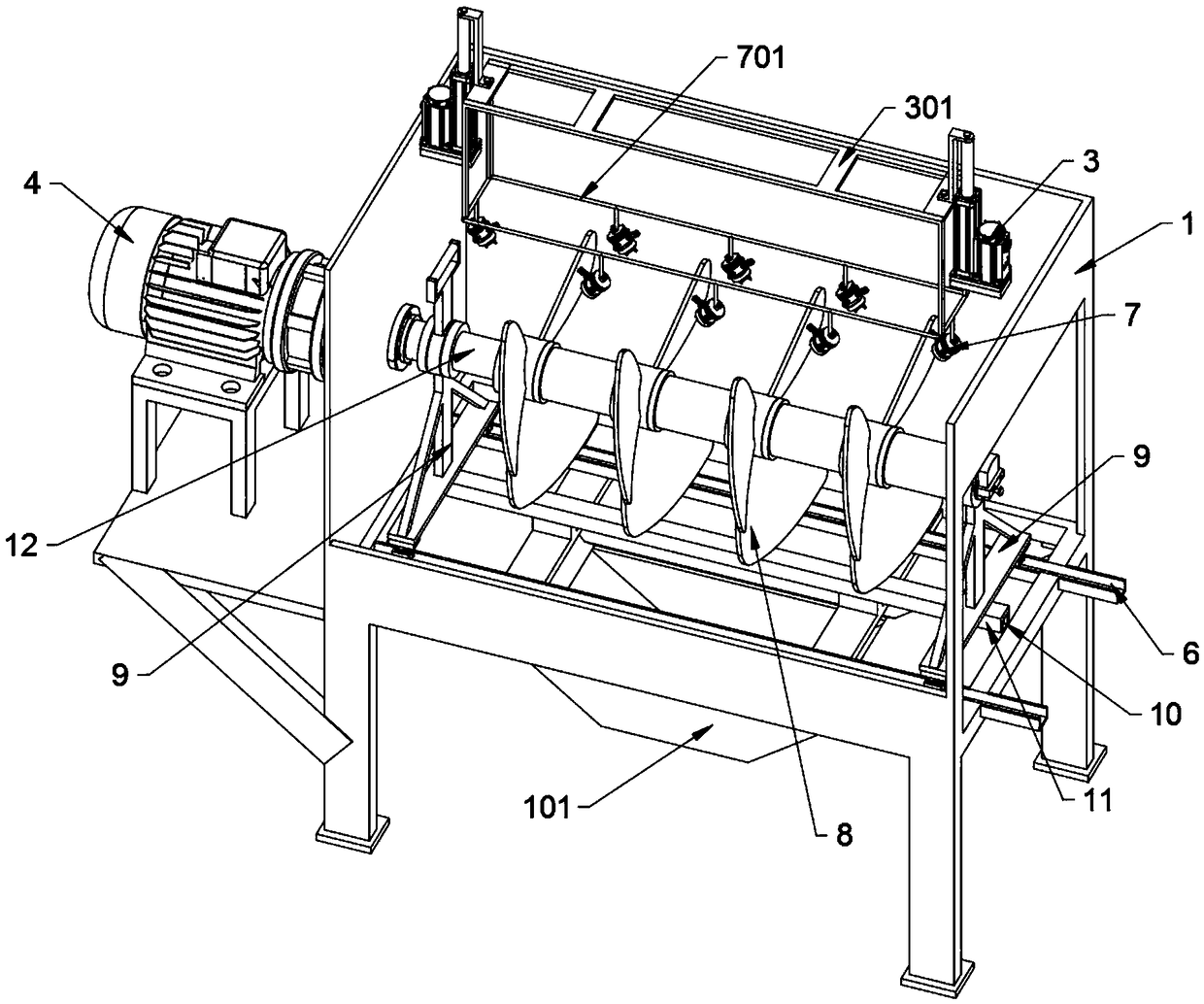

[0033] as attached figure 1 to attach Figure 11 Shown:

[0034]The present invention provides a paint spraying device for electromechanical fan blades equipped with a cover structure, comprising a box body 1, a paint-poly cover 101, a water tank 1011, a threaded connecting pipe 102, a box door 2, an electric cylinder 3, an electric cylinder hanger 301, Motor 4, square insert rod 401, control panel box 5, track 6, nozzle 7, nozzle installation frame 701, fan blade 8, spacer sleeve 801, bracket 9, collar 901, positioning rod 10, chute 11, rotation support shaft 12. Insert frame 1201, insert plate 13, positioning frame 14 and pressing rod 14; a box door 2 is pivotally hinged on the rear side wall of the box body 1, and a box door 2 is hinged at the bottom, and a paint gathering cover 101 is hung by welding at the bottom. The bottom of the paint 101 is welded and hung with a water tank 1011, and a copper ball valve is screwed in the middle of the bottom plate of the water tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com