Multi-face and multi-hole perforating device capable of achieving one-time formation and using method thereof

A multi-faceted porous and punching equipment technology, applied in drilling/drilling equipment, boring/drilling, metal processing equipment, etc. Strength, the effect of improving the efficiency of punching processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

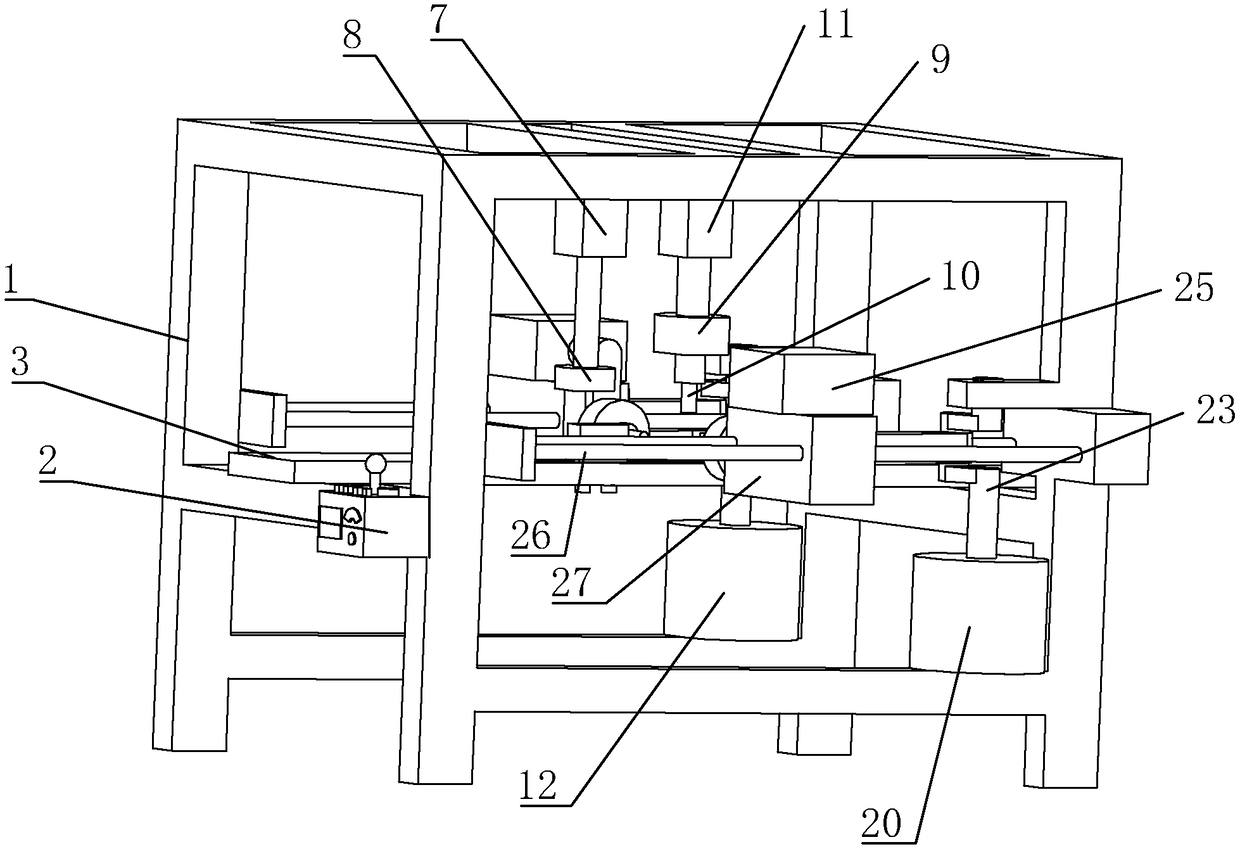

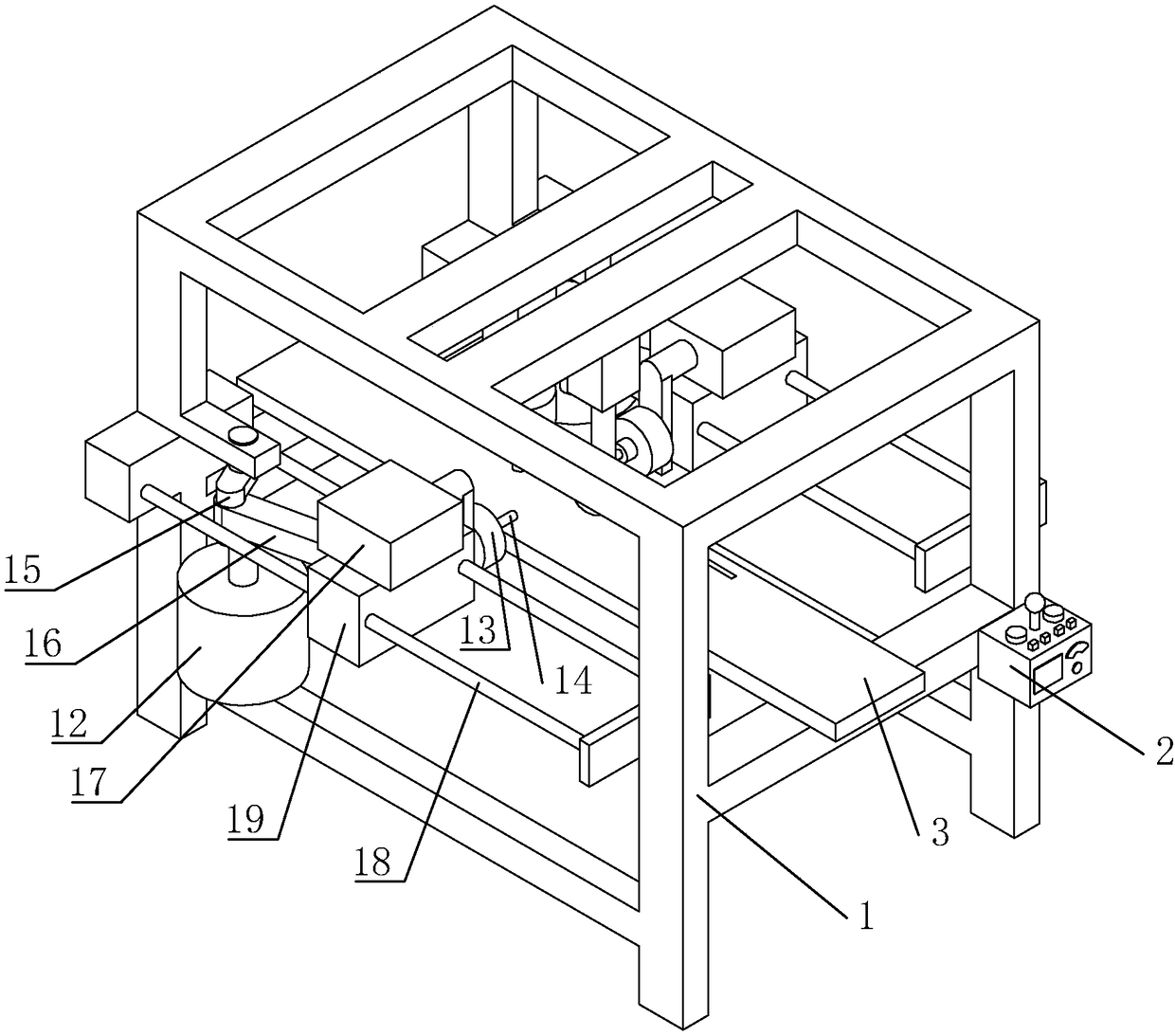

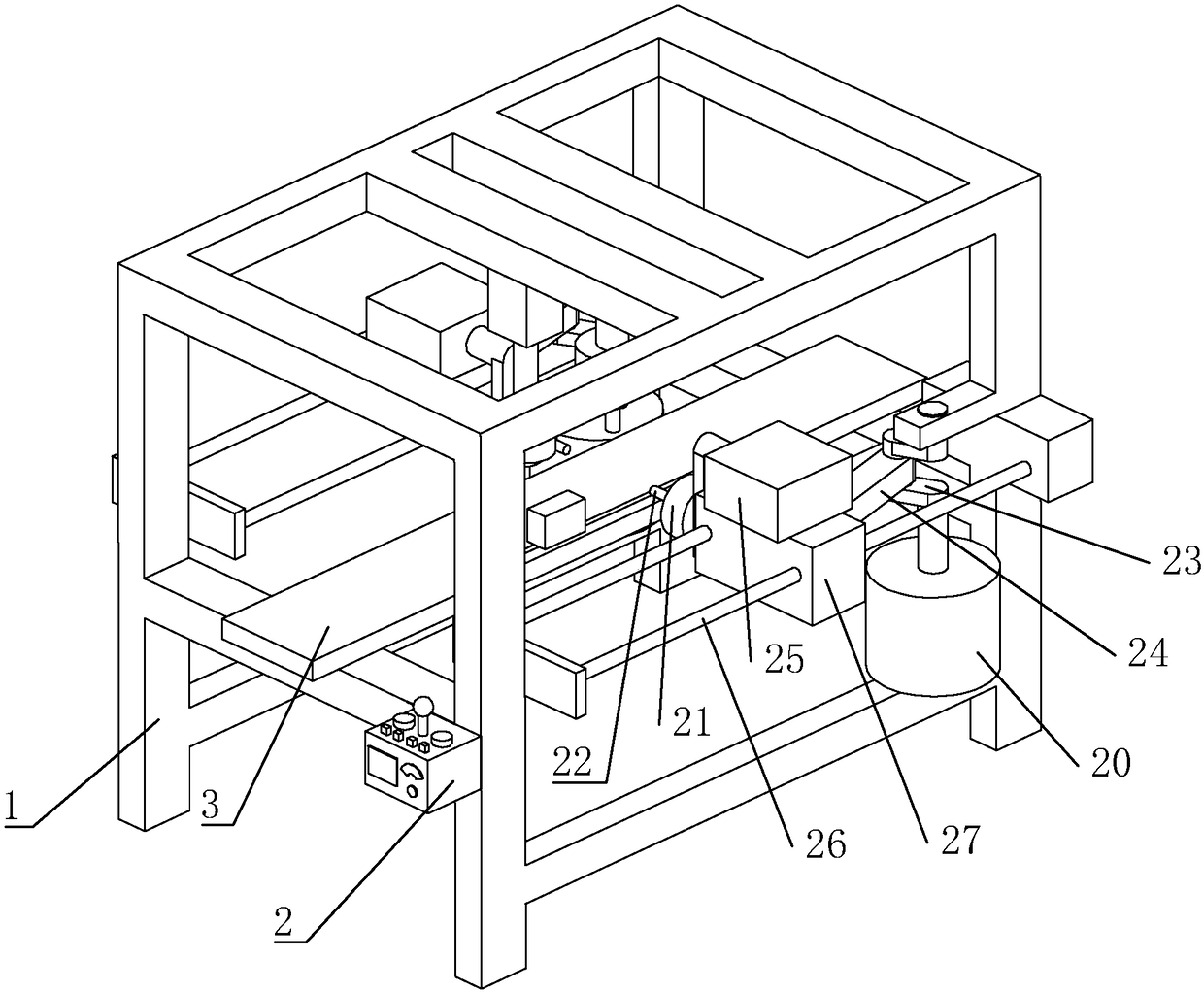

[0032] refer to Figures 1 to 5 As shown, a multi-faceted multi-hole position one-time forming and punching equipment in this embodiment includes a body 1, a controller 2, an operating platform, a positioning device and a punching device, the operating platform is arranged on the body 1, and the positioning device It is installed on the operating platform for positioning and fixing the chair legs on the operating platform. The punching device is arranged on the body 1 for punching the chair legs. The controller 2 is installed on the body 1 , the controller 2 is respectively connected to control the positioning device and the punching device.

[0033] The operating platform includes a placing platform 3 and a positioning block 4 , the placing platform 3 is fixedly installed on the machine body 1 , and the positioning block 4 is detachably installed on the placing platform 3 .

[0034] The placement platform 3 is provided with a through groove 5 consistent with the length direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com