Flexible polishing device

A flexible and grinding mechanism technology, which is applied in the direction of grinding drive devices, grinding machines, grinding frames, etc., can solve the problems of complex structure, incompatibility, and high cost, and achieve the effect of reliable operation and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

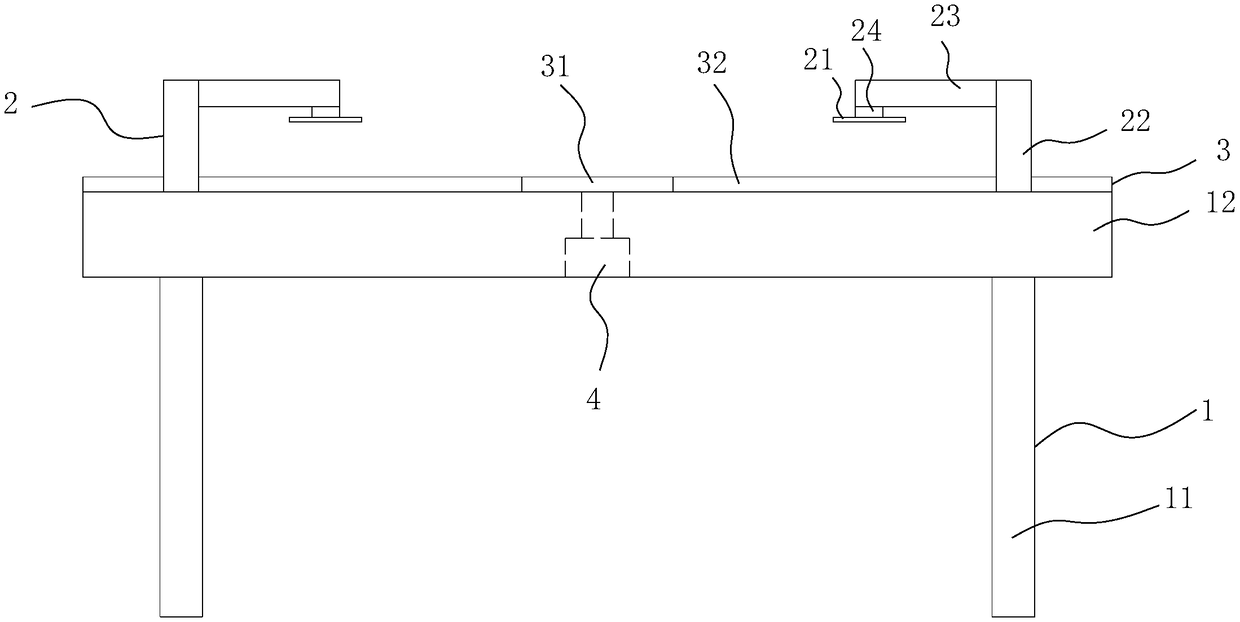

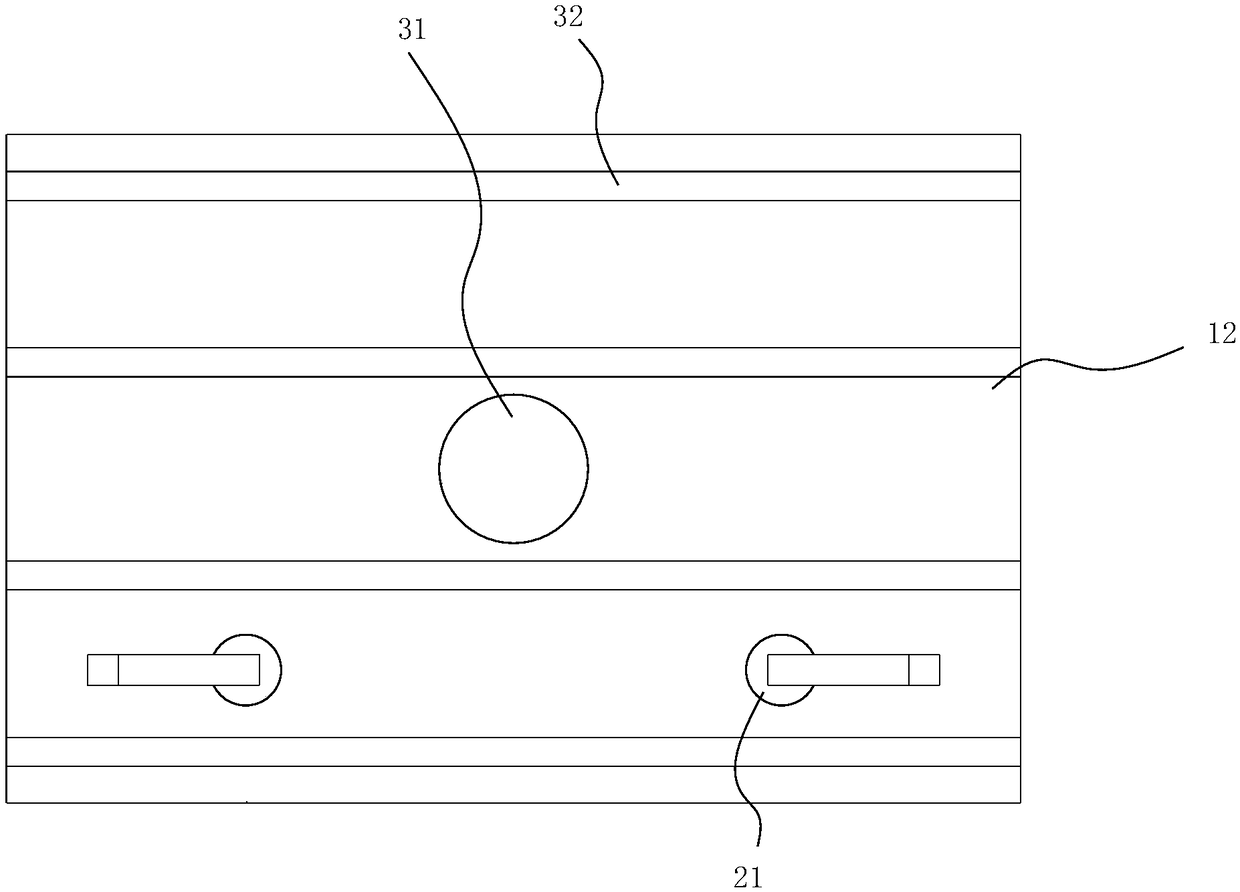

[0014] The present invention as Figure 1-2 As shown, it includes a frame 1, a grinding mechanism 2 and a moving mechanism 3, and the frame includes a pair of columns 11 and a workbench 12 arranged on a pair of columns;

[0015] The grinding mechanism 2 is arranged on the workbench and is used for grinding the plate;

[0016] The moving mechanism 3 includes a rotary table 31 and a plurality of roller shafts 32, the rotary table is arranged in the middle of the table through a lifting mechanism, and several roller shafts are arranged at intervals.

[0017] In the working process of the present invention, the aluminum plate is placed on the workbench, rotated by the rotating workbench, or the roller shaft is moved to realize continuous grinding and improve work efficiency. The rotary table can be driven by a rotating motor, and the roller shaft can be driven by a motor; the height of the rotary table and the roller shaft is the same, and they are in contact with the aluminum pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com