Special single-particle grinding head based on abrasive belt grinding

A belt grinding and single-grain technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding automatic control devices, etc., can solve the problem that the grinding mechanism cannot be fully applied and hinders the development of grinding technology, etc. problems, to achieve the effect of improving visibility, reducing management and production costs, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

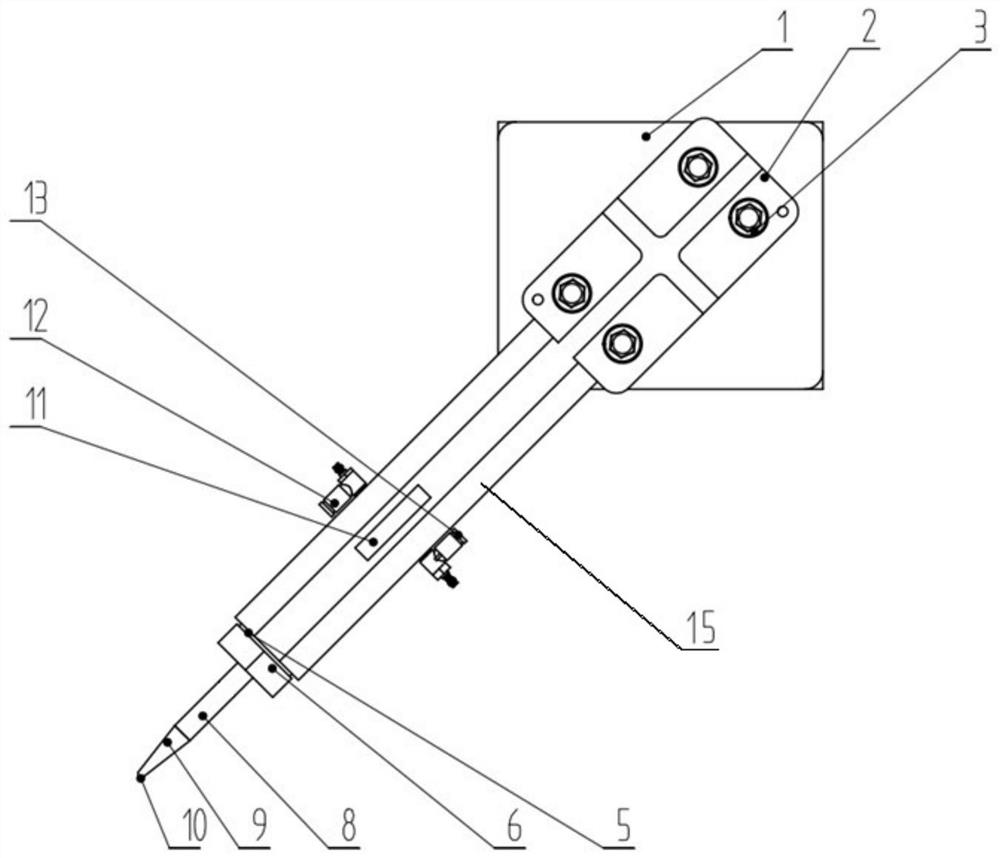

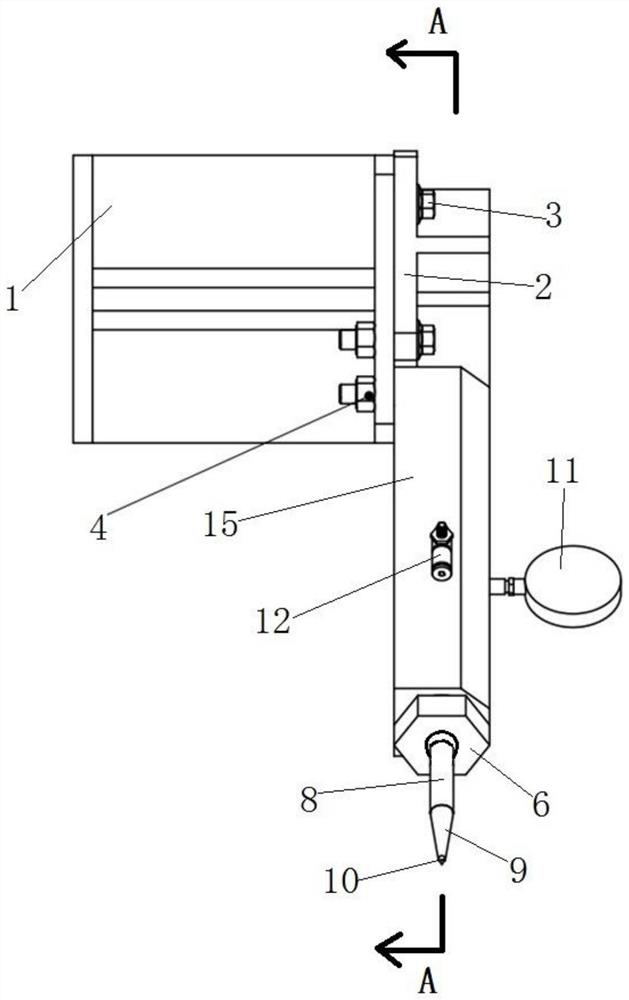

[0025] This embodiment discloses a special single-grain grinding head based on abrasive belt grinding, including an adapter plate 1, a support frame 2, a perforated bolt 6, a piston 8, an abrasive seat 9, replaceable diamond abrasive grains 10 and a grinding head Subject 15.

[0026] see figure 1 Or 2, one end of the grinding head main body 15 is connected to the support frame 2, and the support frame 2 is connected to the adapter plate 1 by a plurality of bolts 3 and a plurality of nuts 4, and one end of the adapter plate 1 is a joint of a corresponding machine tool or robot .

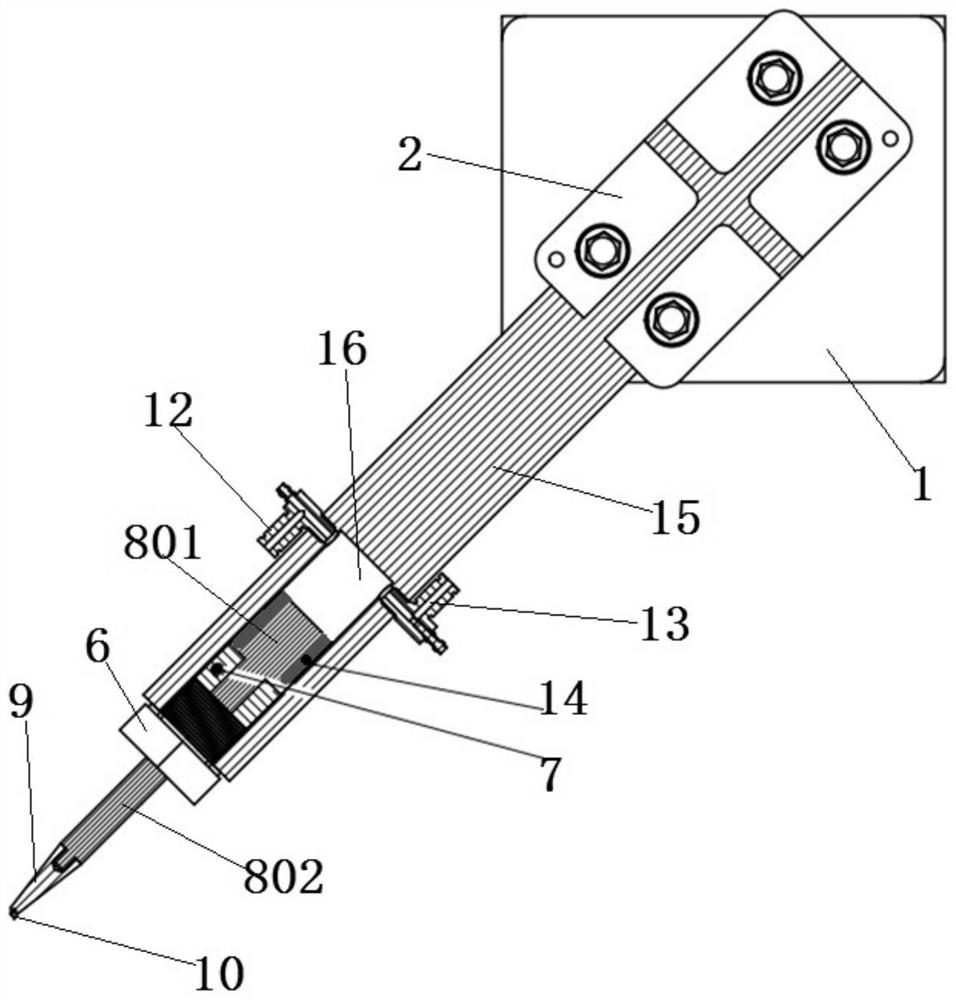

[0027] see image 3 , the grinding head body 15 is provided with a cylinder 16, one end of the cylinder 16 runs through the end of the grinding head body 15 away from the support frame 2, and the open end of the cylinder 16 is provided with an internal thread.

[0028] The perforated bolt 6 is screwed into the open end of the cylinder 16, a washer 5 is arranged between the bolt head of the perforat...

Embodiment 2

[0036] This embodiment discloses a special single-grain grinding head based on abrasive belt grinding, including an adapter plate 1, a support frame 2, a perforated bolt 6, a piston 8, an abrasive seat 9, replaceable diamond abrasive grains 10 and a grinding head Subject 15.

[0037] see figure 1 Or 2, one end of the grinding head body 15 is connected to the support frame 2, the support frame 2 is connected to the adapter plate 1, and one end of the adapter plate 1 is a joint of a corresponding machine tool or robot.

[0038] see image 3 , the grinding head body 15 is provided with a cylinder 16, one end of the cylinder 16 runs through the end of the grinding head body 15 away from the support frame 2, and the open end of the cylinder 16 is provided with an internal thread.

[0039] The perforated bolt 6 is screwed into the open end of the cylinder 16 , and the through hole 601 is provided on the perforated bolt 6 , and the through hole 601 communicates with the cylinder 16...

Embodiment 3

[0046] The main structure of this embodiment is the same as that of Embodiment 2, further, refer to figure 2 , the support frame 2 is connected to the adapter plate 1 by a plurality of bolts 3 and a plurality of nuts 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com