Gear deburring device

A technology for deburring and gears, applied in the direction of grinding drive devices, grinding/polishing safety devices, manufacturing tools, etc., can solve the problems of uneven deburring process between gear teeth, damage to gear tooth profile, etc., to achieve uniform size, Grinding evenly and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

[0016] The reference signs in the accompanying drawings of the specification include:

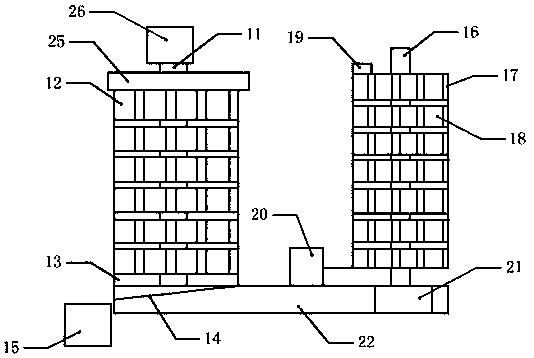

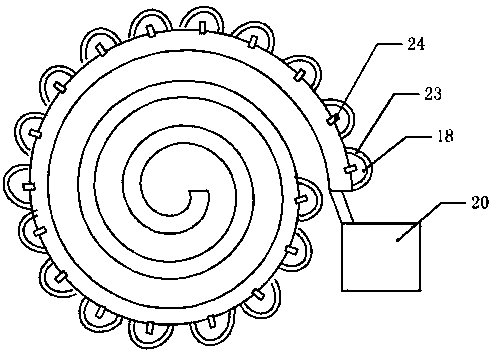

[0017] First shaft 11, gear 12, filter screen 13, partition 14, collection tank 15, second shaft 16, tape 17, air bag 18, buckle 19, blower 20, cylinder 21, base 22, fine sandpaper 23, single To air inlet 24, baffle plate 25, motor 26.

[0018] Such as figure 1 The shown gear deburring device includes a hollow base 22, a first rotating shaft 11 is installed on the left side of the base 22, a second rotating shaft 16 is installed on the right side of the base 22, five gears 12 to be processed are pierced on the first rotating shaft 11, The tooth slots of the gears 12 on the first rotating shaft 11 communicate vertically, the upper end of the first rotating shaft 11 is connected to the motor 26, the lower end of the first rotating shaft 11 is equipped with a filter screen 13 made of so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com