Plastic mold inclined roof structure with sliding block

A plastic mold and lifter technology, which is applied in the field of advanced manufacturing and automation, can solve the problems of complex parts structure, increase the size of the lifter, and need to replace parts, etc., to achieve the effect of low application cost, prevention of movement overrun, and improvement of yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

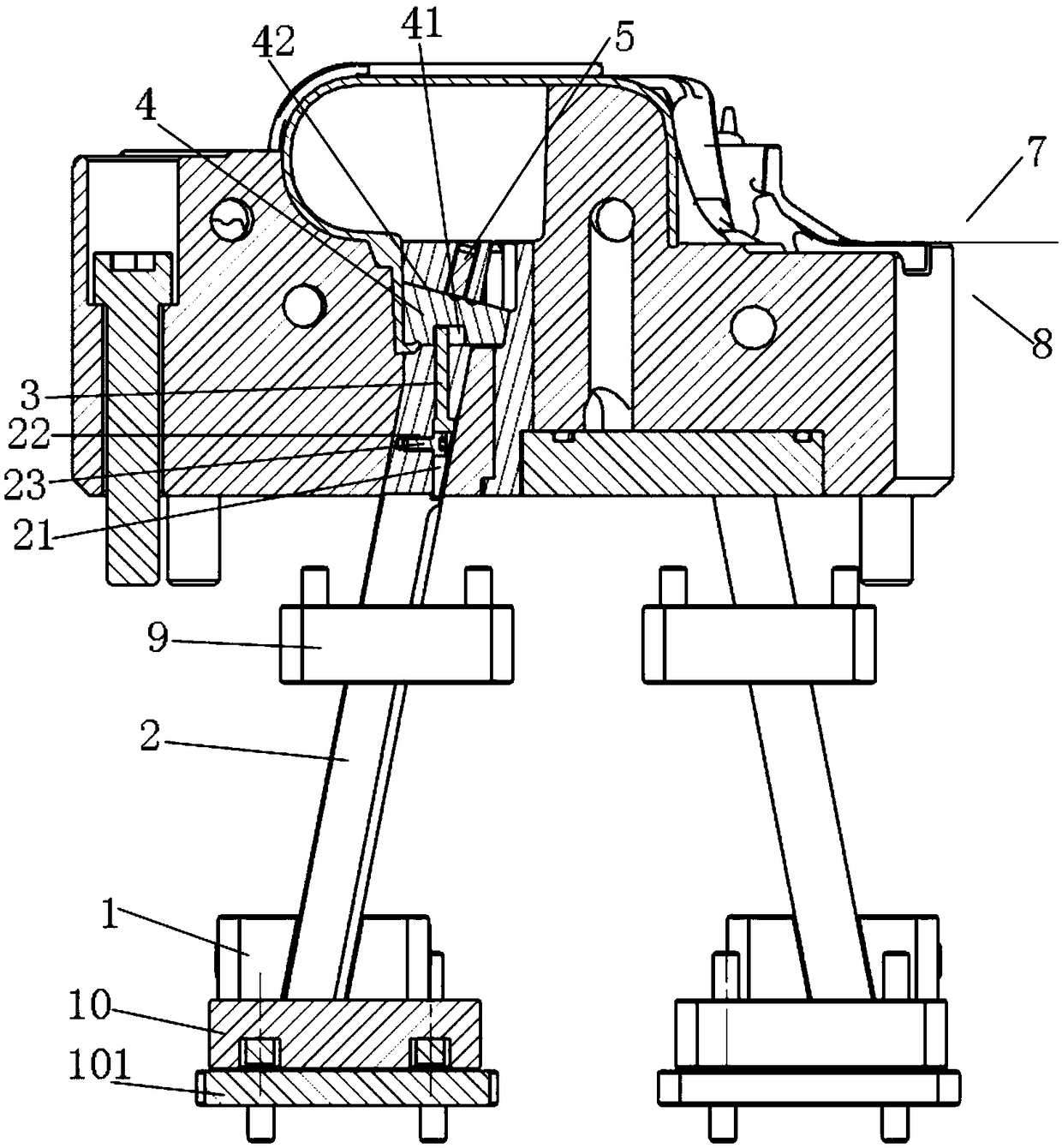

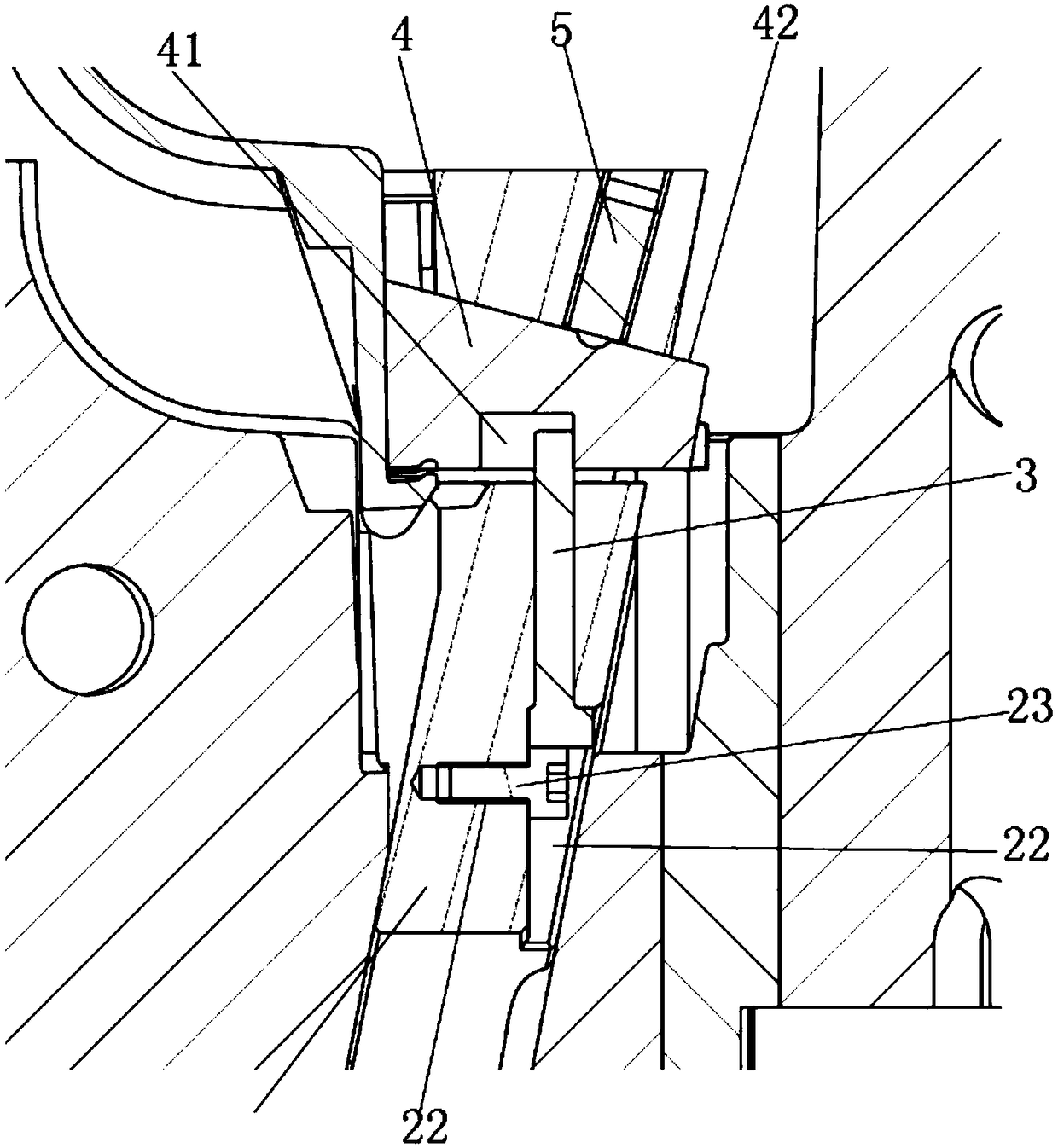

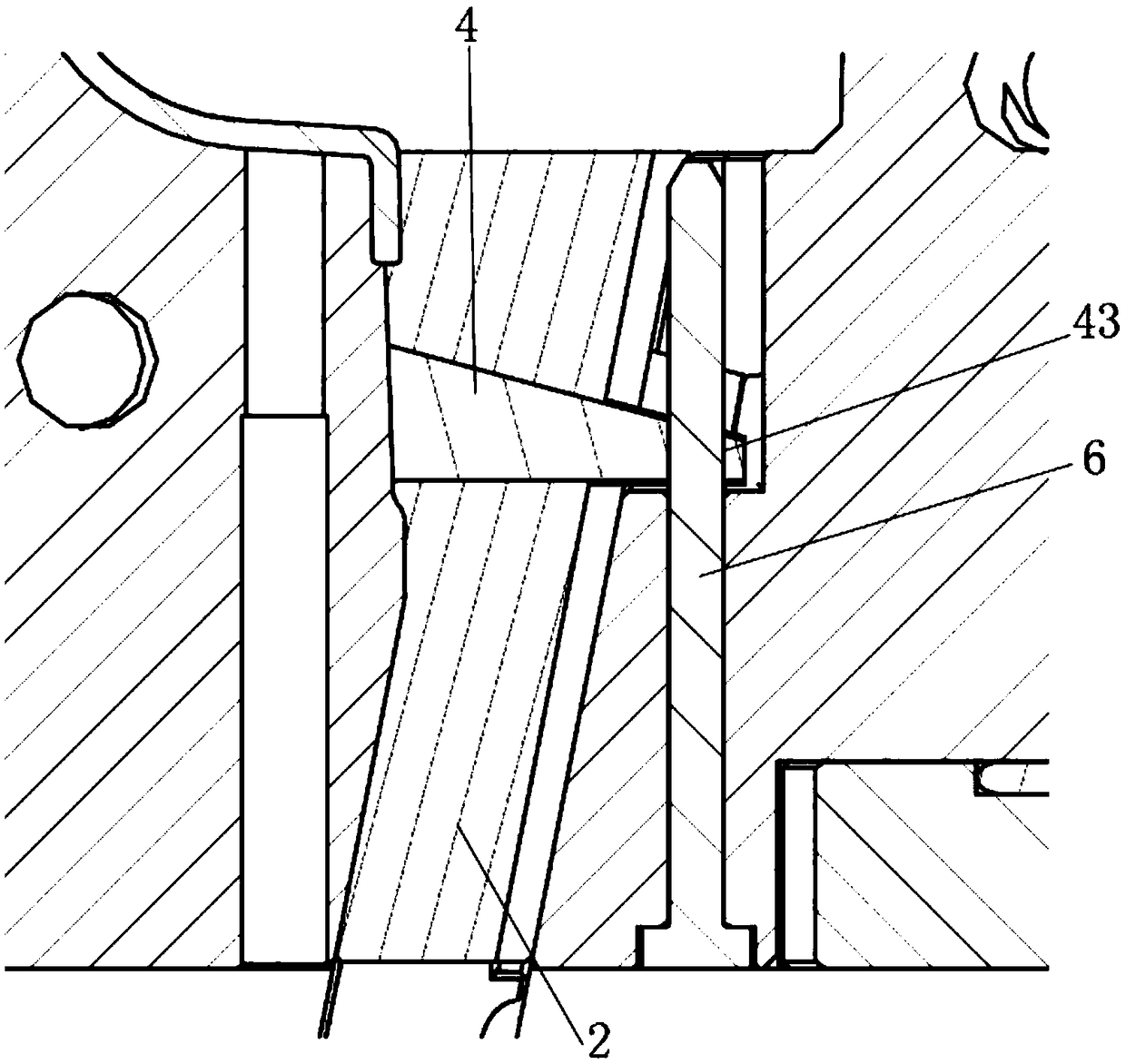

[0033] Such as Figure 1-3The inclined roof structure of the plastic mold with the slider shown includes the inclined roof seat 1, the inclined roof 2, the inner slider bar 3, the inner slider 4 of the inclined roof, the inner slider positioning ball screw 5, and the vertical guide rod 6. On the fixed mold side 7 and the movable mold side 8, the inclined roof 2 is arranged obliquely. The end faces are fitted together, the lower end surface of the inner slider 4 of the inclined roof is provided with a first groove 41, the inner slider bar 3 is arranged in the inclined roof 2, and the upper end of the inner slider bar 3 is arranged on In the first groove 41, the inner slider positioning ball screw 5 is arranged on the fixed mold side 7, and the lower end of the inner slider positioning ball screw 5 is attached to the upper end surface of the inclined top inner slider 4, The vertical guide rod 6 is vertically arranged in the movable mold side 8, and the vertical guide rod 6 runs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com