Improved automatic and efficient book binding device

An improved and efficient technology, applied in the direction of bookbinding, etc., can solve the problems of hand injury, high price, force, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

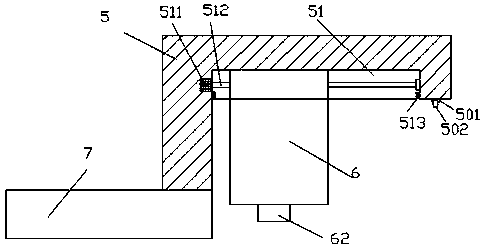

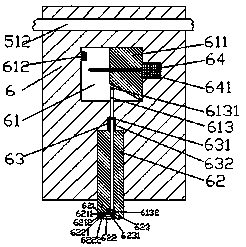

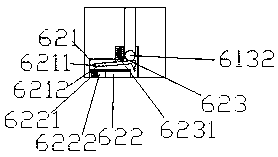

[0016] Such as figure 1 , figure 2 with image 3 As shown, the present invention discloses an improved automatic and efficient book binding device, including a base 7 and a transposition body 5 fixedly arranged on the outer surface of the upper right part of the base 7, and the top of the transposition body 5 A transposition guide chute 51 is arranged in the lower side, and a horizontal transposition driving device is fixedly arranged in the transposition guide chute 51, and first contact sensors 513 are arranged on the inner walls of the left and right sides. The top of the transposition body 5 In the lower side, the top wall of the transposition guide chute 51 is connected to the binding machine body 5 in a sliding fit, and the top of the binding machine body 5 is provided with a first adjusting screw rod 512 in the transposition guide chute 51 in a threaded manner. In the inner screw-shaped hole, a first sliding guide cavity 61 is provided in the middle of the binding machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com