A metal dust treatment device and method

A metal dust and processing device technology, applied in transportation and packaging, vehicle cleaning, locomotives, etc., can solve the problems of shortened service life of electrical boxes, huge cleaning workload, metal dust intrusion, etc., to reduce maintenance costs and reduce human costs. Working frequency and the effect of optimizing operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

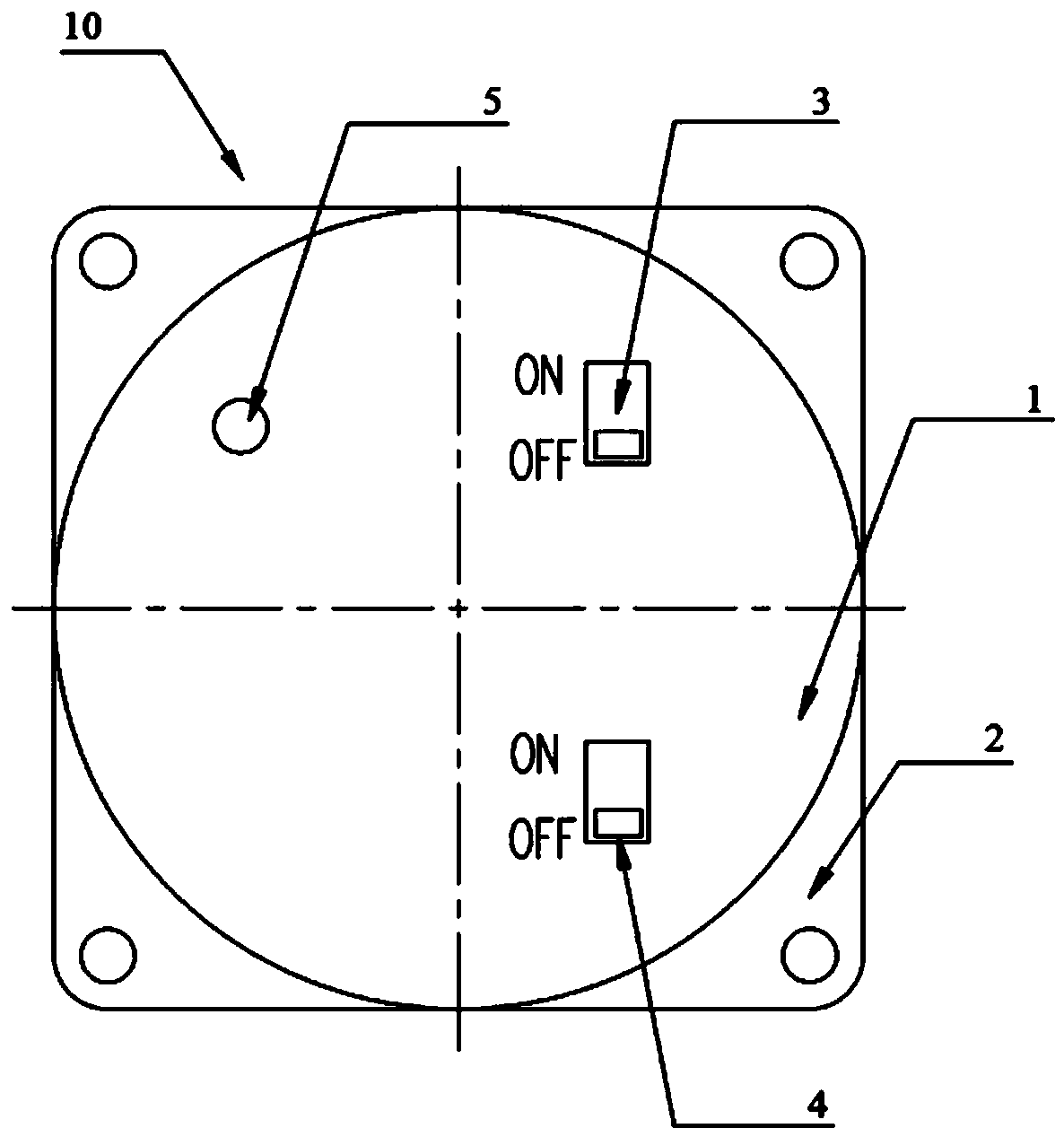

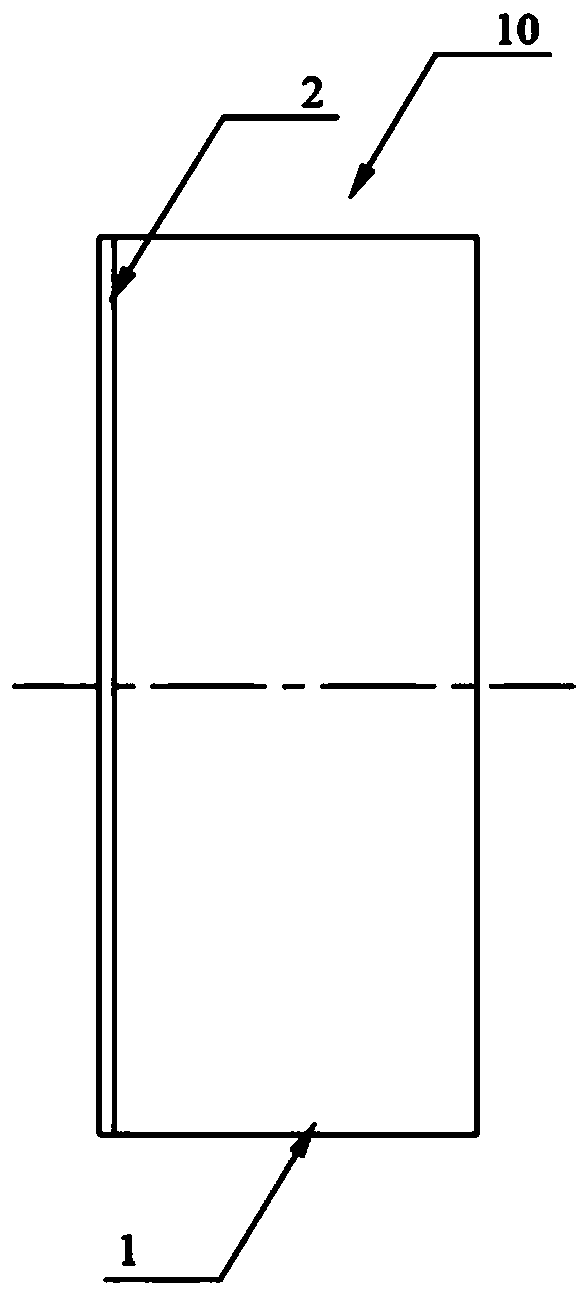

[0048] as attached figure 1 To attach image 3 As shown, an embodiment of a metal dust treatment device, the metal dust treatment device 10 specifically includes:

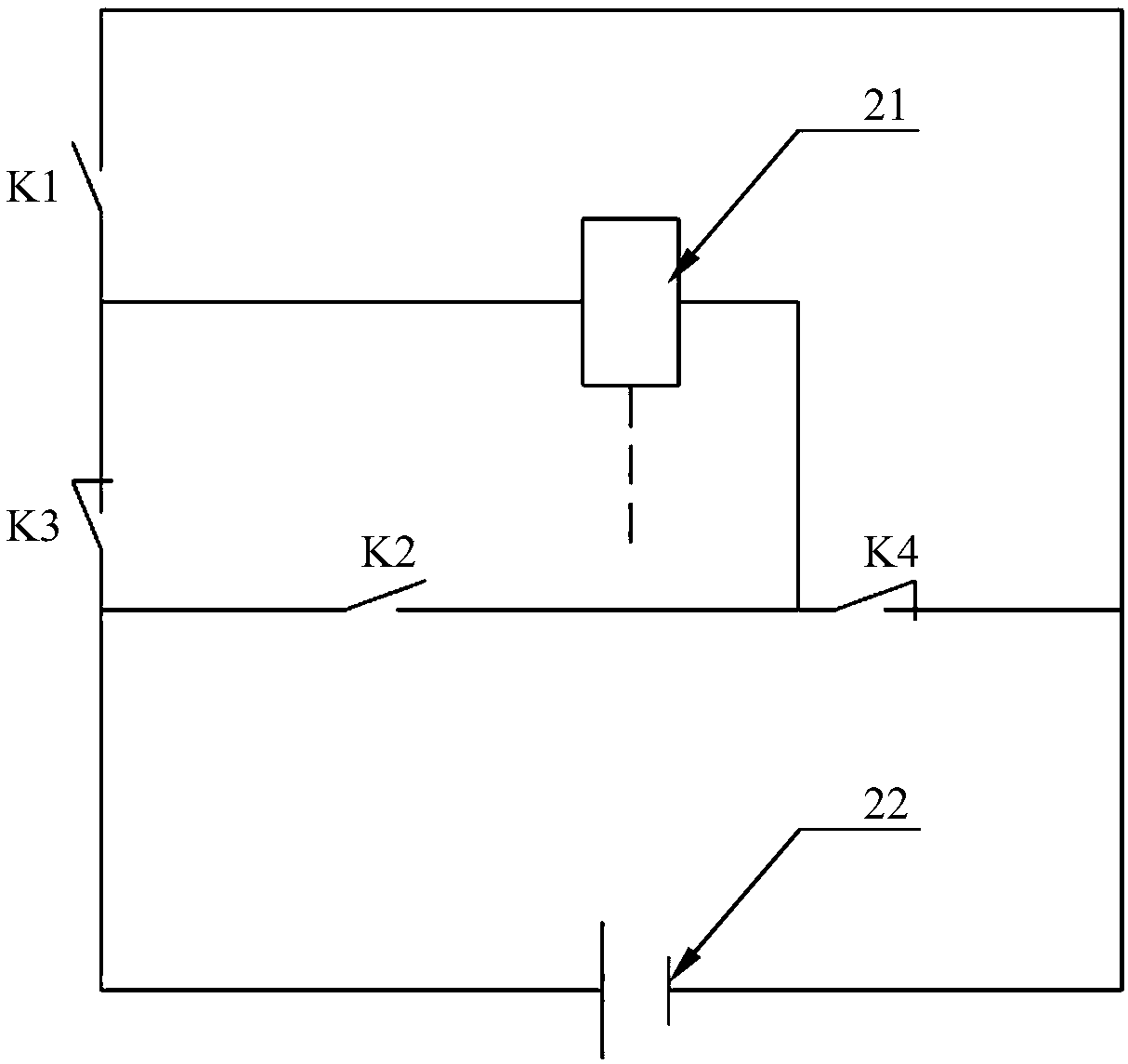

[0049] The adsorption module 1 encapsulates the electromagnet 21, the power supply 22, the magnetizing switch 3 and the demagnetizing switch 4 as one;

[0050] The power supply 22 provides the electric energy needed for the electromagnet 21 to work;

[0051] The magnetizing switch 3 is used to connect the forward magnetizing circuit of the power supply 22 and the electromagnet 21;

[0052] The demagnetization switch 4 is used to connect the reverse demagnetization circuit of the power supply 22 and the electromagnet 21, and change the current direction of the electromagnet 21;

[0053] And it is located at the installation bottom of the adsorption module 1, and is used to fix the adsorption module 1 to the mounting seat 2 on the side of the wheelset 6 (the wheelset 6 is made of carbon steel, which is an excellen...

Embodiment 2

[0059] Another embodiment of the metal dust treatment device, the metal dust treatment device 10 specifically includes:

[0060] The adsorption module 1 encapsulates the electromagnet 21, the power supply 22, the magnetizing switch 3 and the demagnetizing switch 4 as one;

[0061] The power supply 22 provides the electric energy needed for the electromagnet 21 to work;

[0062] The magnetizing switch 3 is used to connect the forward magnetizing circuit of the power supply 22 and the electromagnet 21;

[0063] The demagnetization switch 4 is used to connect the reverse demagnetization circuit of the power supply 22 and the electromagnet 21, and change the current direction of the electromagnet 21;

[0064] And the mounting base 2 located at the installation bottom of the adsorption module 1 for fixing the adsorption module 1 on the fender 7 of the wheel set 6 .

[0065] as attached Figure 5 As shown, different from Embodiment 1, in this embodiment, a fender 7 is respectivel...

Embodiment 3

[0068] as attached Figure 6 As shown, on the basis of Embodiments 1 and 2, the metal dust treatment device 10 further includes a package packaged in the adsorption module 1 and connected in series with the electromagnet 21 for adjusting the forward magnetization current or reverse demagnetization of the electromagnet 21. Current adjustable resistor VR. By increasing the adjustable resistance VR, it is very convenient to control the magnitude of the forward magnetizing current or the reverse demagnetizing current, neither will cause abnormality of the wheel set 6 due to the excessive electromagnetic force causing other metal substances made of steel to be absorbed. cause a fault, and will not cause even the worn metal powder to be unable to be adsorbed to the end face of the wheel set 6 or the fender 7 because the electromagnetic force is too small. The metal dust treatment device 10 further includes an indicator light 5 packaged in the adsorption module 1 and connected in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com