All-dimensional adjustable material receiving device

A material receiving device and all-round technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of inconvenient access for workers, uneven material boxes, etc., to save finishing time, simple structure and stable work good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

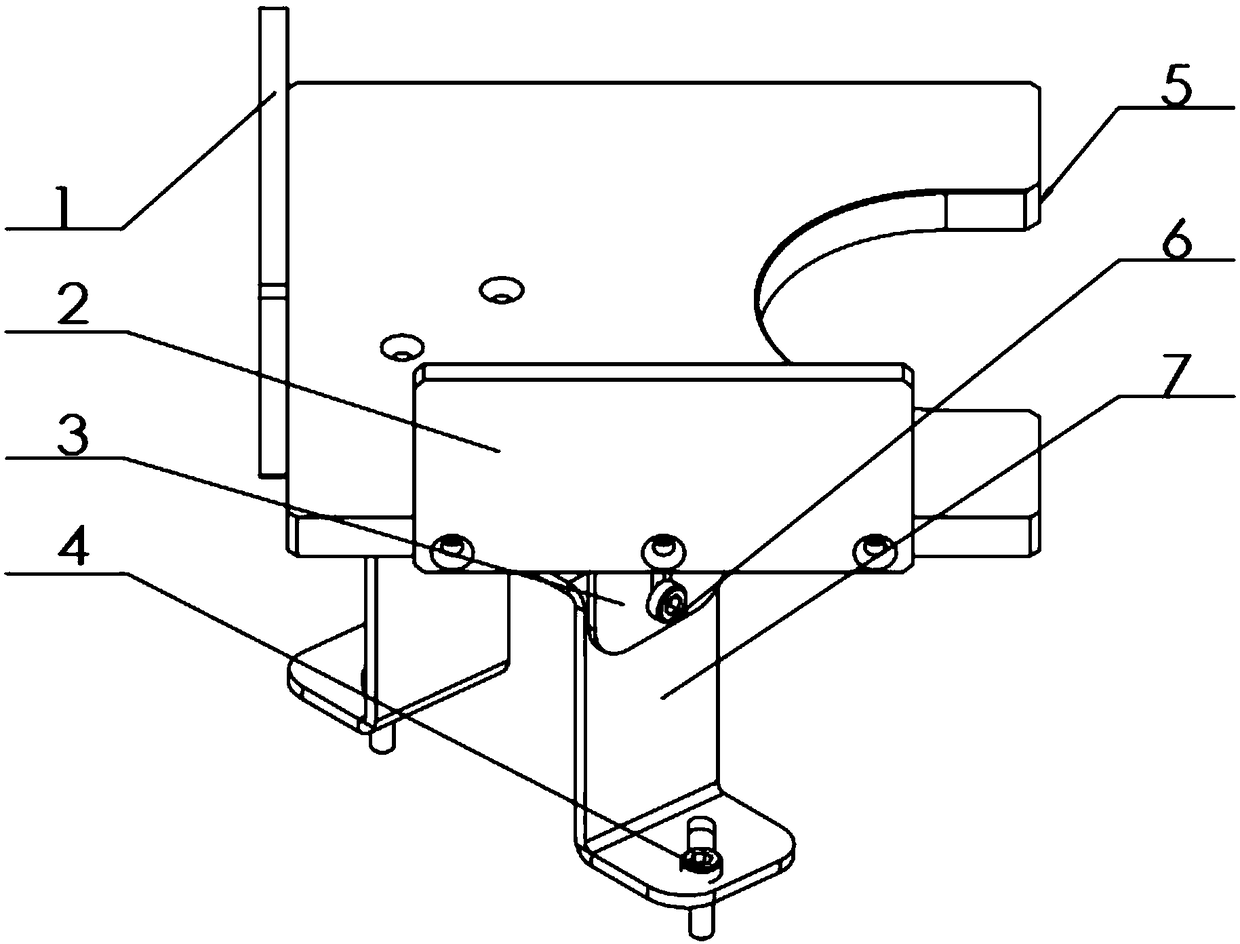

[0007] Such as figure 1 As shown, the present invention has two retaining sides 1 and 2, the angle and the upper and lower adjustment plate 3, and the material box bottom bracket 5 to be fixed together by screws to form an upper assembly; the bottom support plate 7 is adjusted by two front and rear adjustment screws 4 and The outer bottom plate is connected to form the lower component; the upper and lower components are adjusted up and down and the angle through the elastic fit of two up and down adjustment screws 6 and flat elastic pads between the upper component and the lower component; the bottom support plate 7 is adjusted through two front and rear adjustment screws The tightness of 4 can adjust the entire assembly forward and backward; the entire structure can be adjusted quickly by adjusting the two front and rear adjustment screws 4 and the two up and down adjustment screws 6.

[0008] The above-mentioned specific embodiments are only exemplary, and are intended to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com