Dot-matrix handheld electric felting needle

A technology of dot-matrix and puncture needles, which is applied in the field of dot-matrix handheld electric lancets, can solve the problems of high labor intensity, low operation efficiency, and poor accuracy, and achieve the effects of reduced labor intensity, reduced labor costs, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

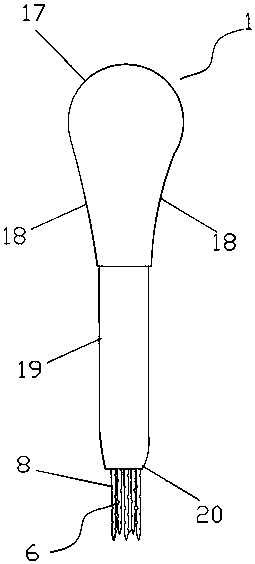

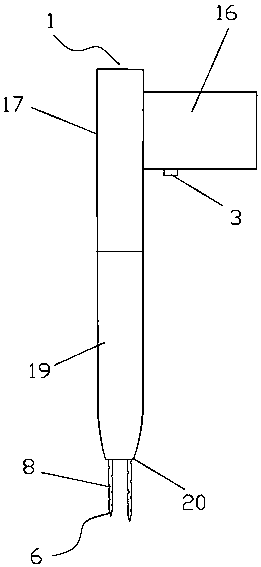

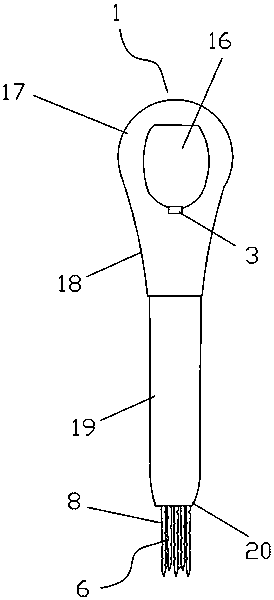

[0039] exist figure 1 , Figure 4 , Figure 5 In the shown embodiment, a dot-matrix handheld electric puncture needle includes:

[0040] The holding part 1 is a holding body with a design structure based on the principles of human biology and dynamic structure;

[0041] The motor 2 is an electric component arranged inside the holding part 1 for providing power; the holding part 1 is provided with a tact switch 3 for controlling the switch of the motor 2;

[0042] The rocker arm 4 is arranged inside the holding part 1 and is connected to the motor 2 and driven by the motor 2 to realize the swinging movement;

[0043] The connecting rod 5 is connected to the rocker arm 4 in rotation and is driven by the rocker arm 4 to realize the linear movement;

[0044] The needles 6 are arranged in a dot matrix and connected to the connecting rod 5 . One end of the needle 6 with the barb 8 freely extends out of the holding part 1 and is driven by the connecting rod 5 to expand and contra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com