Novel sewing machine lifting pressing foot front lever loose thread nail structure and assembling method thereof

An assembly method and sewing machine technology, which are applied in the field of sewing machine manufacturing, can solve the problems of large differences in installation positions, troublesome installation, and inability to perform careful adjustment, and achieve the effects of easy operation, convenient assembly, and easy local fine-tuning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

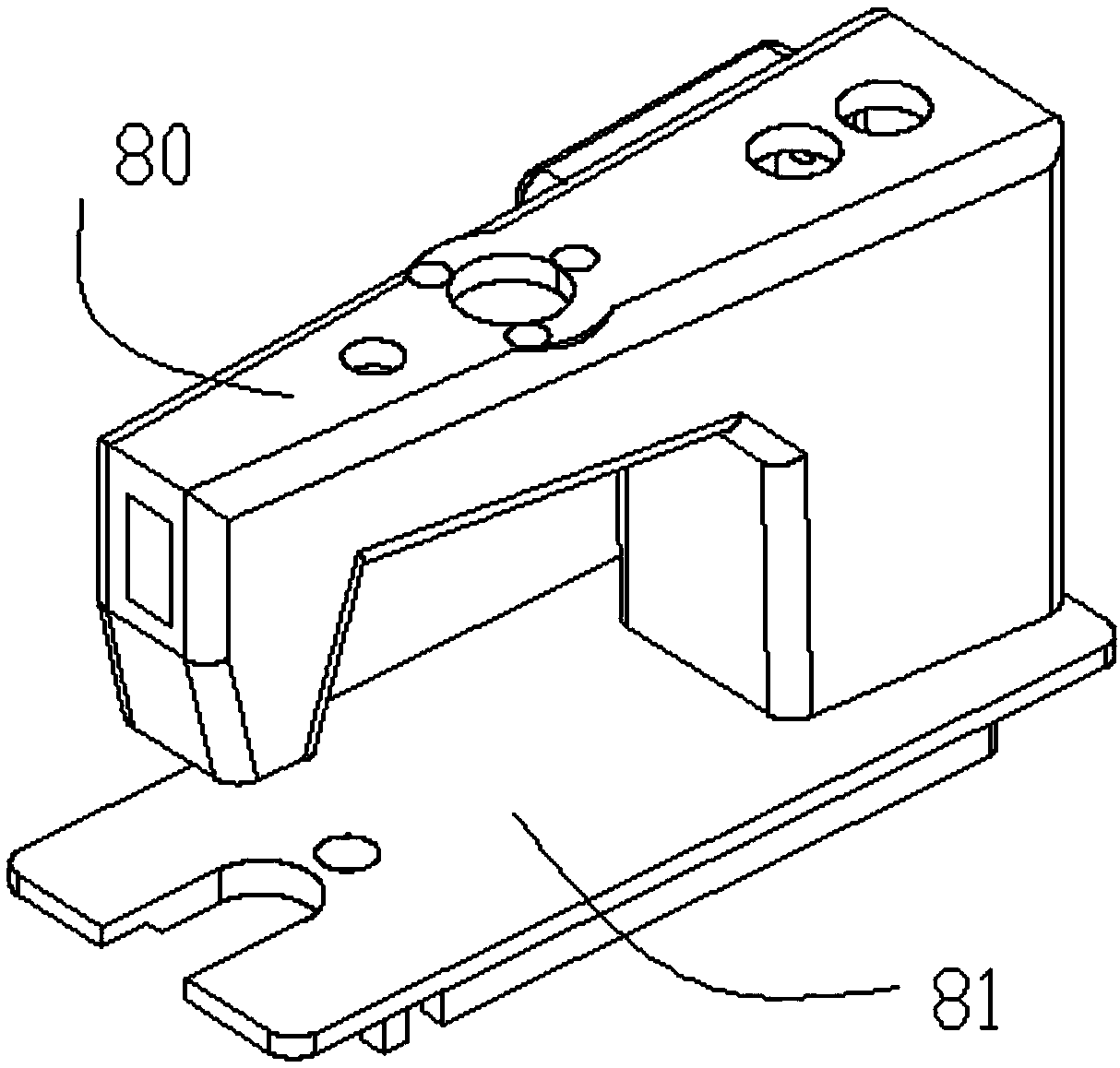

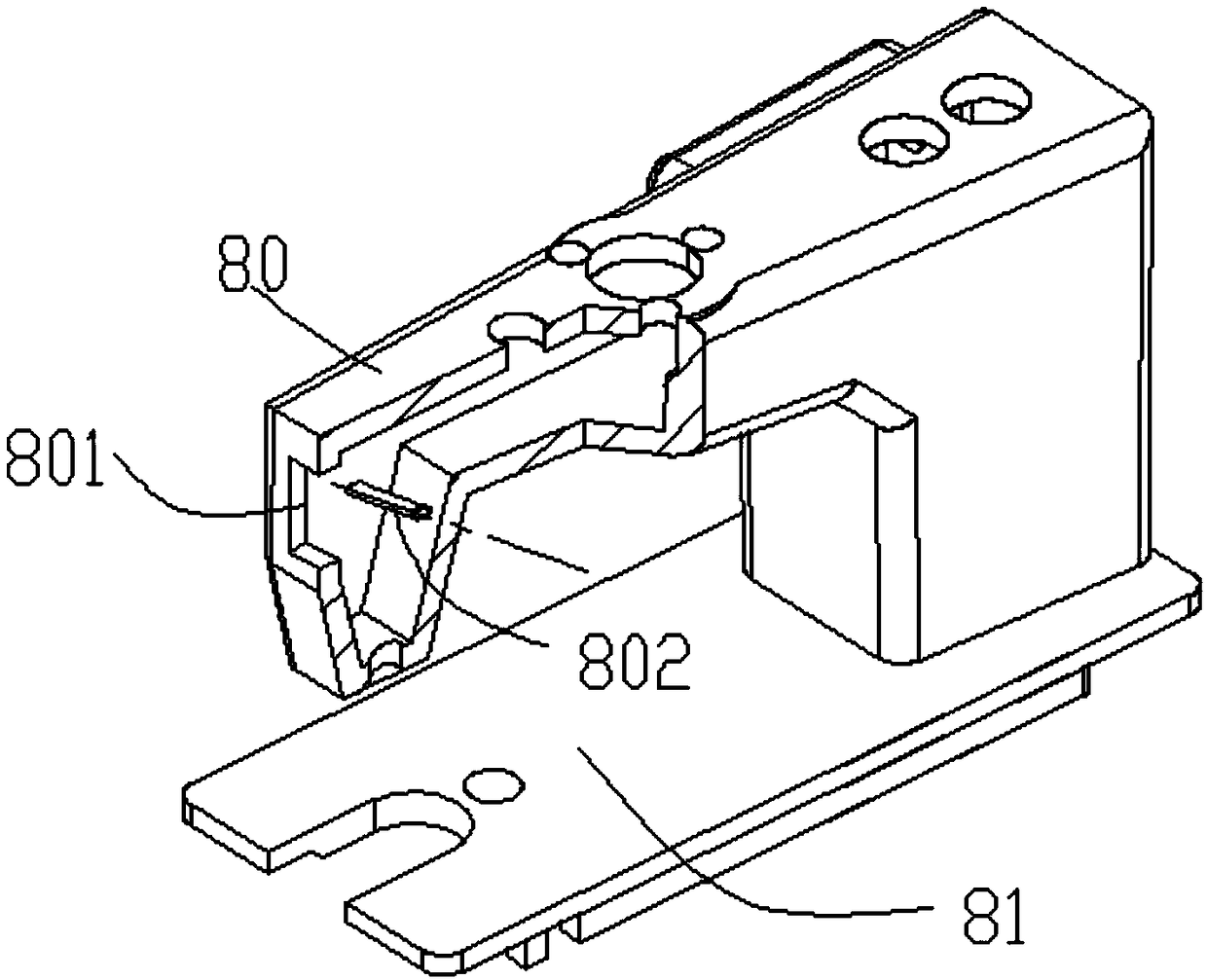

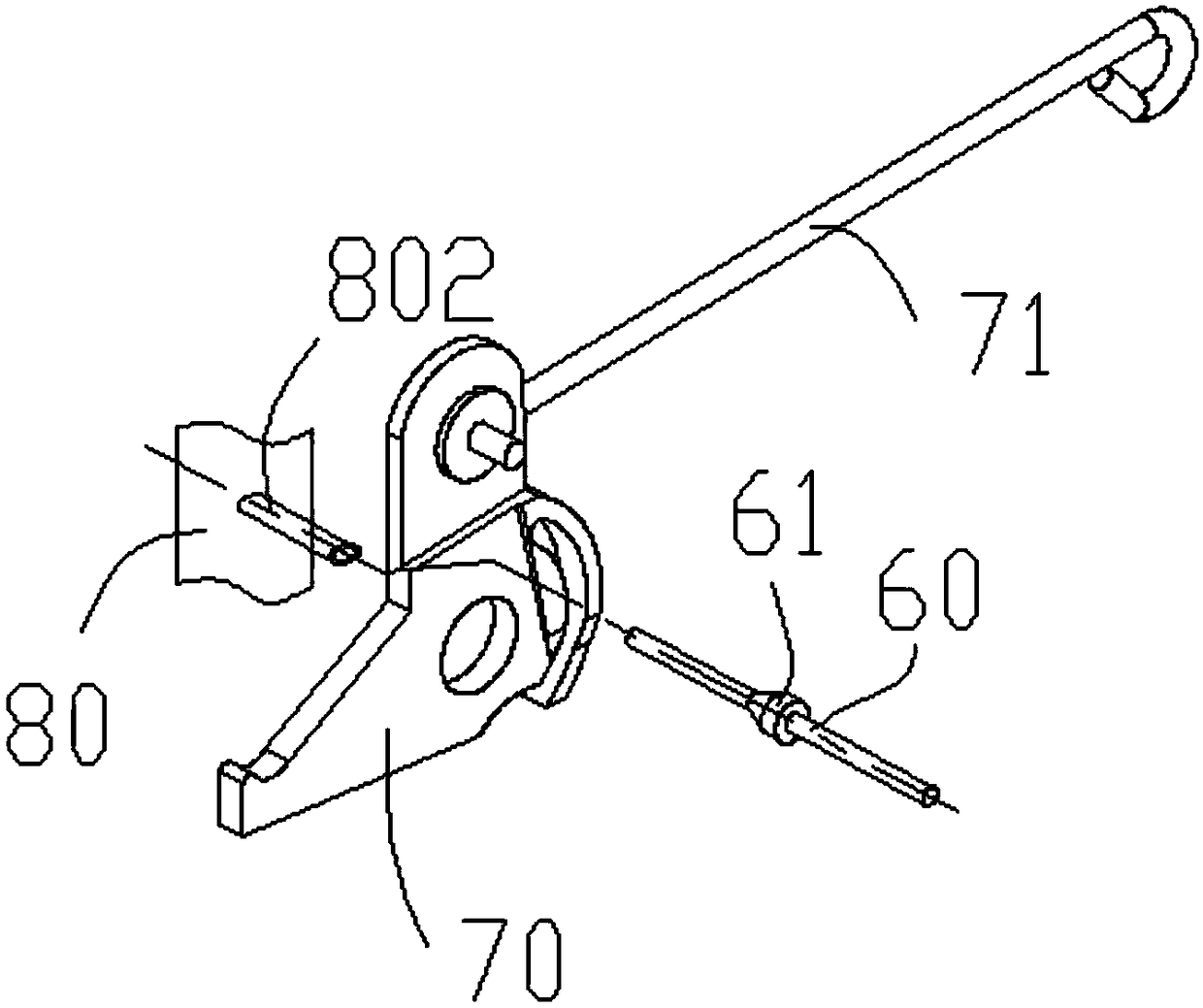

[0032] like Figure 4-Figure 5 As shown, the specific structure of the present invention is: a novel sewing machine presser foot front lever loosening nail structure, which includes a sewing machine head 80 and a machine base 81, and a lever piece is arranged at the front end of the sewing machine at the presser foot rod of the sewing machine. 70, the rear end of the lever piece 70 is hinged with a pull rod 71; the lever piece 70 is provided with a loosening groove 701, and the loosening nail 60 and the inverted cone 61 of the loosening nail in contact with the outer contour of the loosening groove 701...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com