A manufacture method of concrete reserved hole

A manufacturing method and a technology for reserving holes, which are applied in erecting/assembling bridges, bridges, buildings, etc., can solve the problems that steel bars 1 are easy to rust, difficult to pull out, and slide down, so as to ensure construction quality, prolong service life, The effect of improving the adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

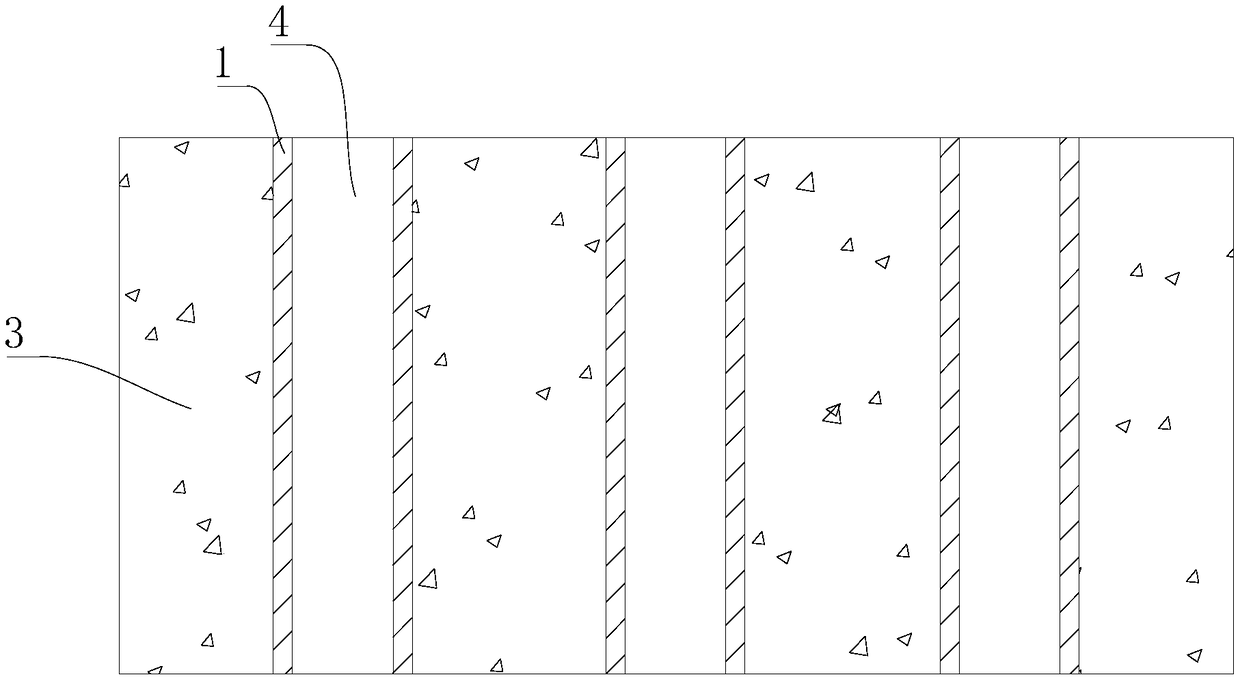

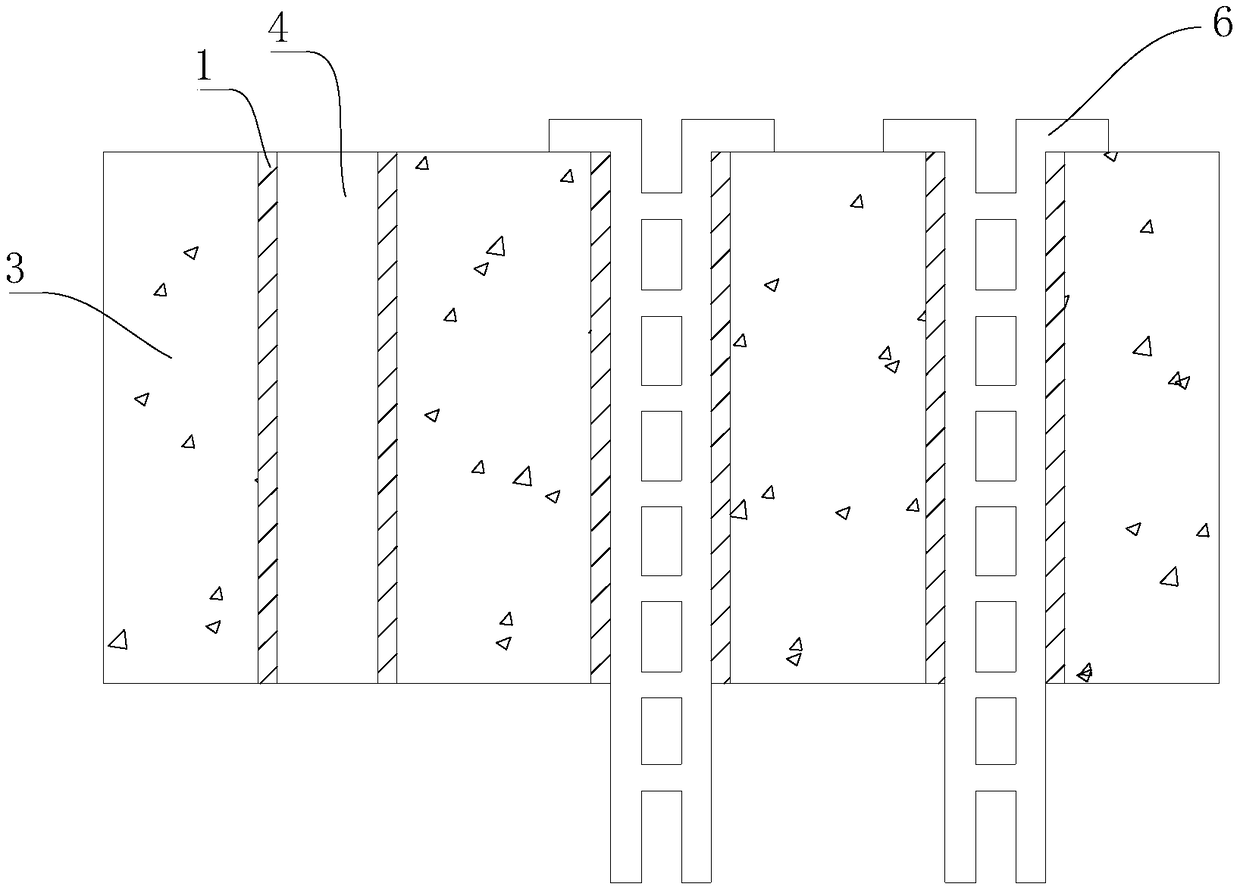

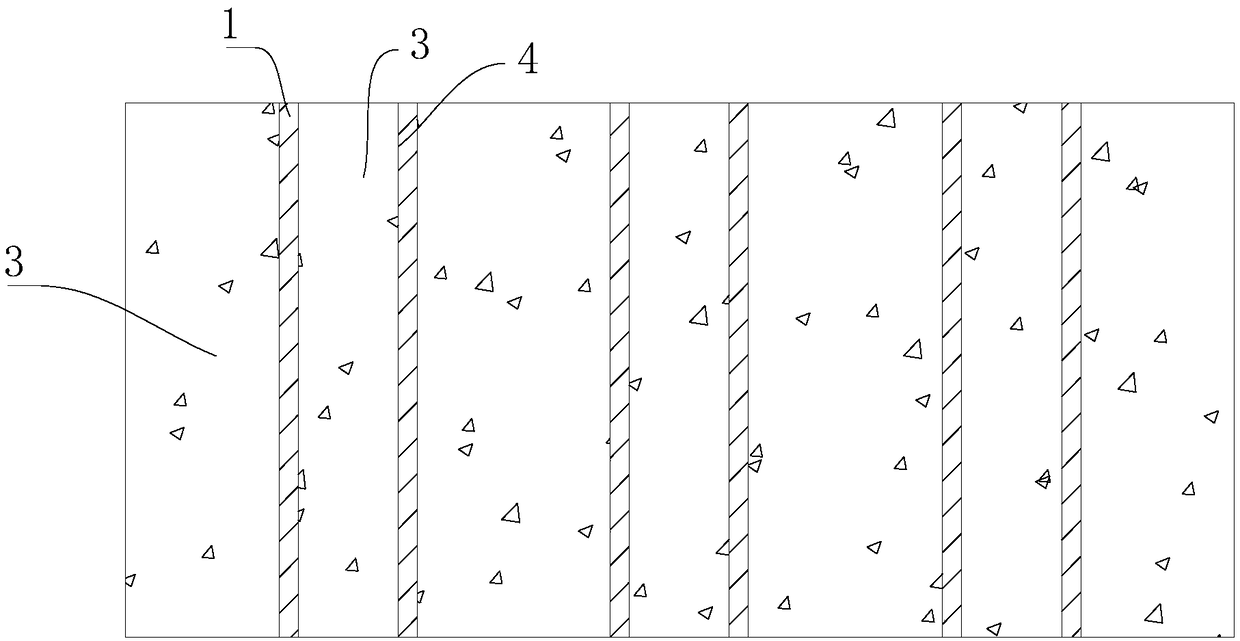

[0039] Embodiment 1: a kind of method for making concrete reserved hole, such as Figure 5 to Figure 8 shown, including the following steps:

[0040] 1.1 To prepare latex starch mixed solution A, first add latex to dilute with water, stir evenly, then add starch to the latex, stir evenly to form latex starch mixed solution A;

[0041] 1.2 Wrap latex starch mixed solution A and paper towel 21 on the surface of the steel rod 1 from inside to outside in turn, and dry until the surface of the steel rod 1 forms a gelatinous film 2;

[0042] 1.3 Embed the processed steel rod 1 in the position corresponding to the reserved hole 4, and pour concrete 3;

[0043] 1.4 After the concrete 3 is dry, pull out the steel rod 1 to form a reserved hole 4 .

[0044] 1.5 Remove the paper towel 21 remaining on the inner wall of the reserved hole 4: fill the reserved hole 4 with water, soak for 1-2 hours, soften the paper towel 21, and use the special tool 5 to mash and scrape the softened paper t...

Embodiment 2

[0051] Embodiment 2: a kind of method for making concrete reserved holes, the difference with embodiment 1 is that the mass and number ratio of water, latex and starch in latex starch mixed solution A is 0.9:1:1.3, in this proportioning Under this condition, it can be guaranteed that the colloidal film 2 will not dry completely within 33 days, and the mass-number ratio of water, latex and starch can be selected according to the construction progress and construction difficulty, so as to ensure economical efficiency.

Embodiment 3

[0052] Embodiment 3: a kind of method for making concrete reserved holes, the difference with embodiment 1 is that the mass and number ratio of water, latex and starch in latex starch mixed solution A is 1.1:1:1.5, in this proportioning Under this condition, it can be guaranteed that the colloidal film 2 will not dry completely within 20 days, and the mass-number ratio of water, latex and starch can be selected according to the construction progress and construction difficulty, so as to ensure economical efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com