A new type of hydraulic gate hoist synchronous control gate system

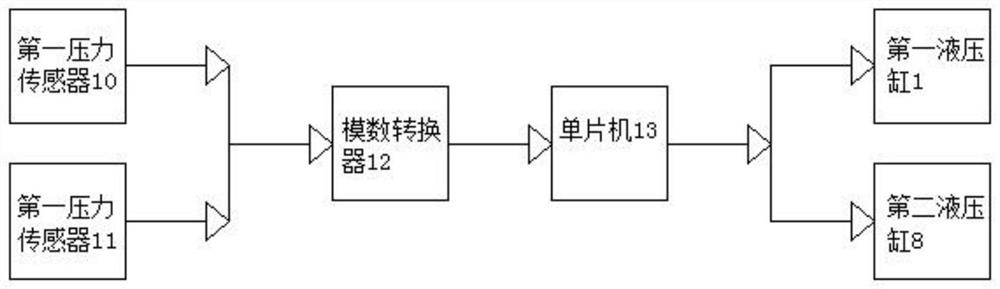

A technology of hydraulic hoist and synchronous control, applied in the field of gates, can solve the problems of inability to perform automatic correction, inability to perform simultaneous detection of two oil cylinders running, and achieve the effects of good energy saving effect, low production cost, and simple and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

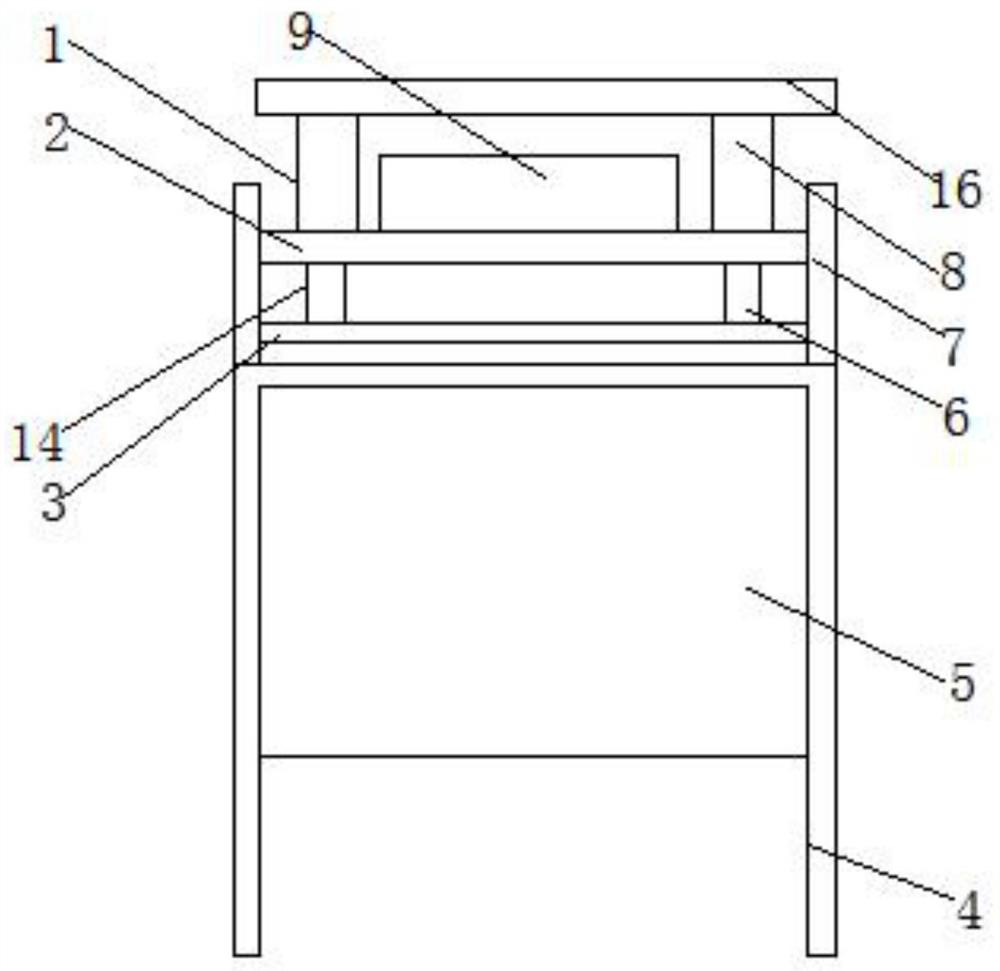

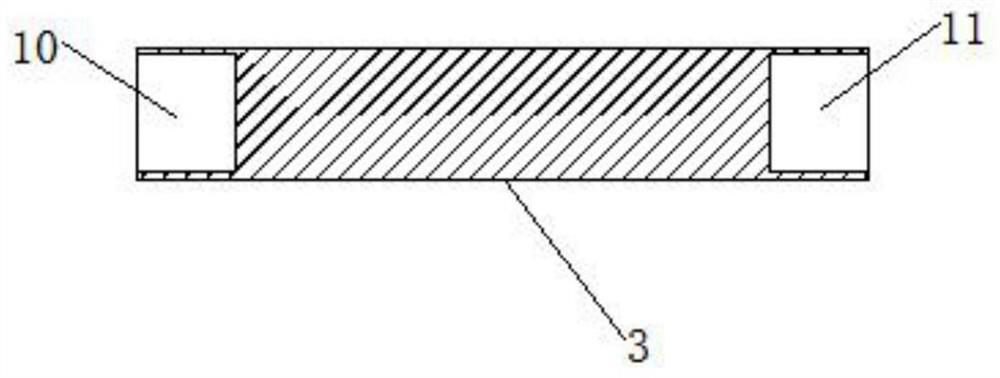

[0019]ReferFigure 1-4A novel hydraulic flap synchronous control gate system, including mounting frame 4, and two upper ends of the mounting frame 4, two mounting plates 7 are fixed, and there is a fixed plate 2 between the two mounting plates 7, the upper ends of the fixed plate 2. There is a first hydraulic cylinder 1 and the second hydraulic cylinder 8, and the second raised lever 14 is fixed at the lower end of the first hydraulic cylinder 1, and the lower end of the second liter 14 passes through the fixing plate 2, and extends below the fixed plate 2, the second hydraulic pressure The lower end of the cylinder 8 fixes a first lift rod 6, and the lower end of the first liter 6 passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com