Discharging and drifting sluice and scouring sluice combined structure

A sand washing and concrete structure technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of limited flow capacity, wide occupied width, and low efficiency, so as to reduce the excavation width and save engineering amount , the effect of reducing the difficulty of layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

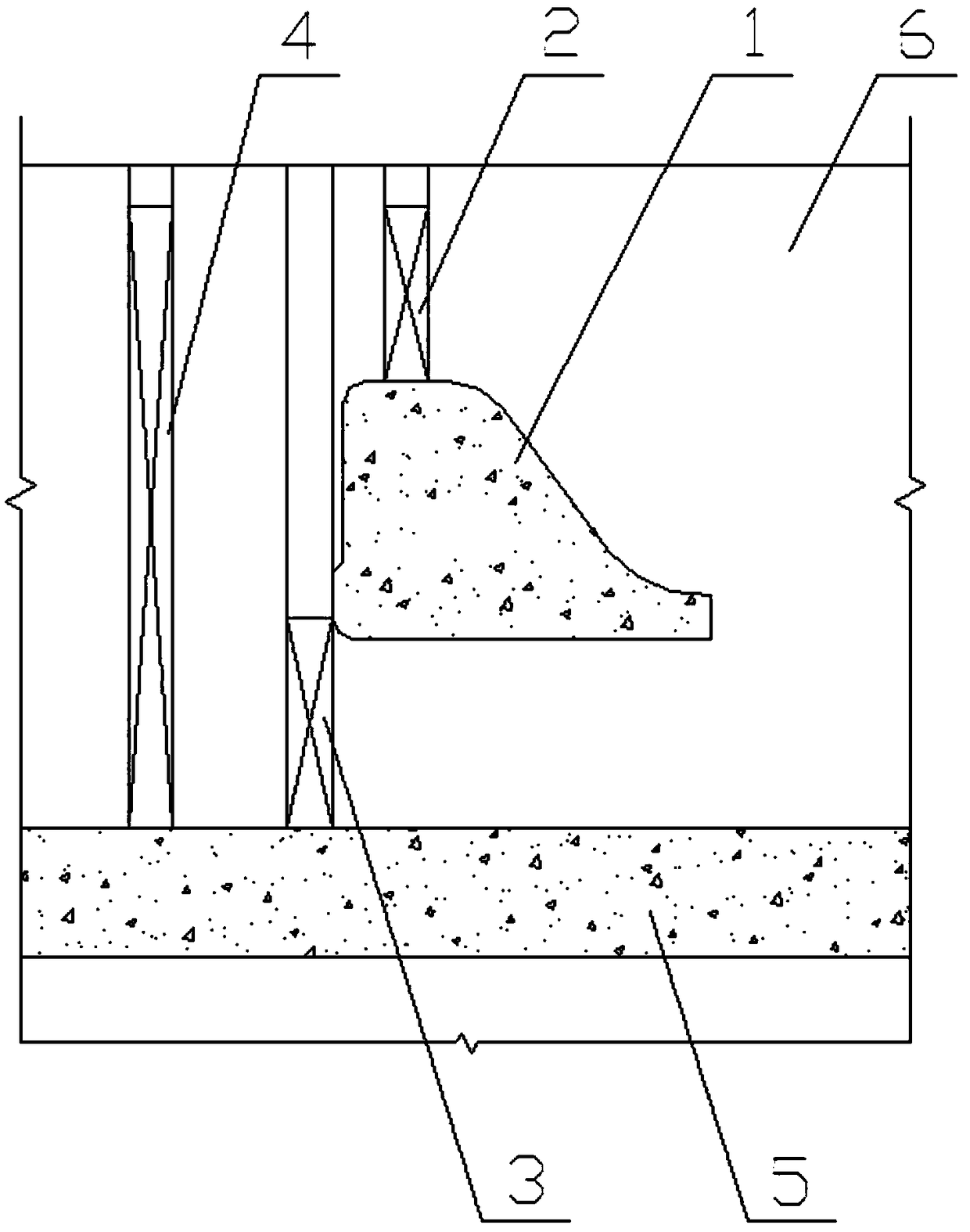

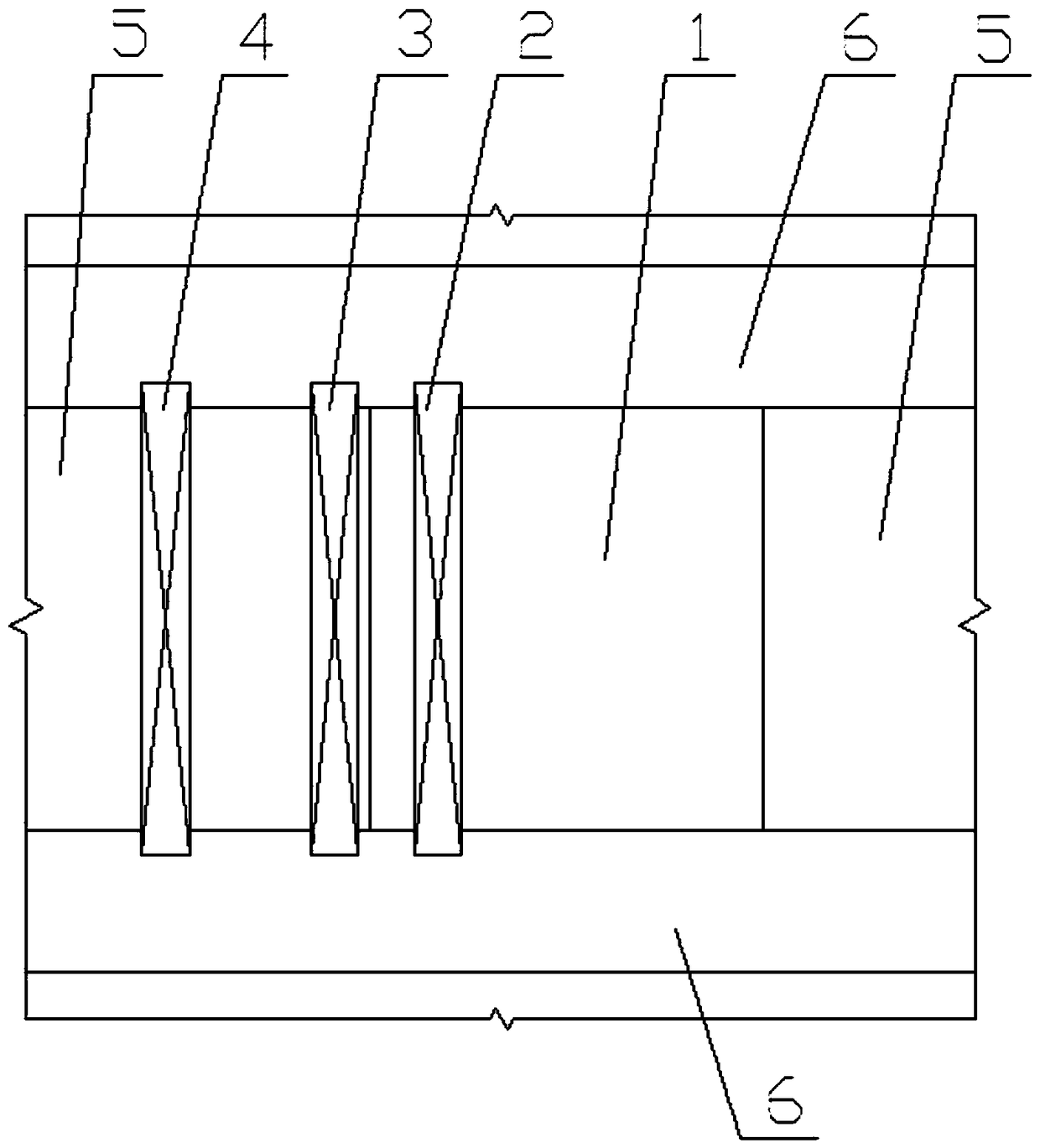

[0017] Such as figure 1 and figure 2 As shown, the present invention comprises gate hole, is provided with overflow weir 1 in the middle part of gate hole, and the weir crest overflow passage of overflow weir 1 is the drift discharge channel, and the drift discharge channel is provided with drift gate 2; Overflow weir 1 bottom and The channel between the gate bottom plates 5 is a sand washing channel, and the sand washing channel is provided with a sand washing gate 3 .

[0018] The drift gate 2 of the present invention adopts the structure of the overflow weir 1, and adopts deflection to connect with the downstream water flow. The sand washing gate 3 is arranged at the lower part of the drift gate 2, and the drift gate 2 and the sand washing gate 3 are combined in vertical layers. Arrangement, shared gate hole width, can reduce the total net width o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com