Tunnel driving shield support and supporting method

A technology for shielding supports and roadways, which is used in mine roof supports, earth-moving drilling, mining equipment, etc., can solve problems such as poor adaptability and complex structure, and achieve the effects of low cost, stable support, and reduced torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

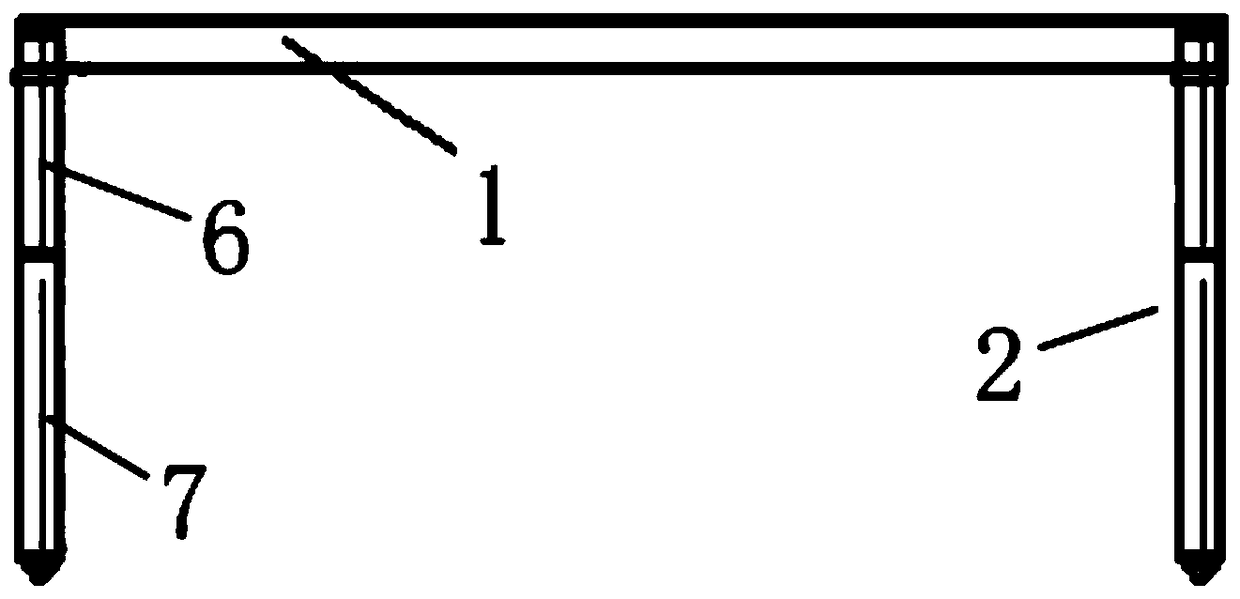

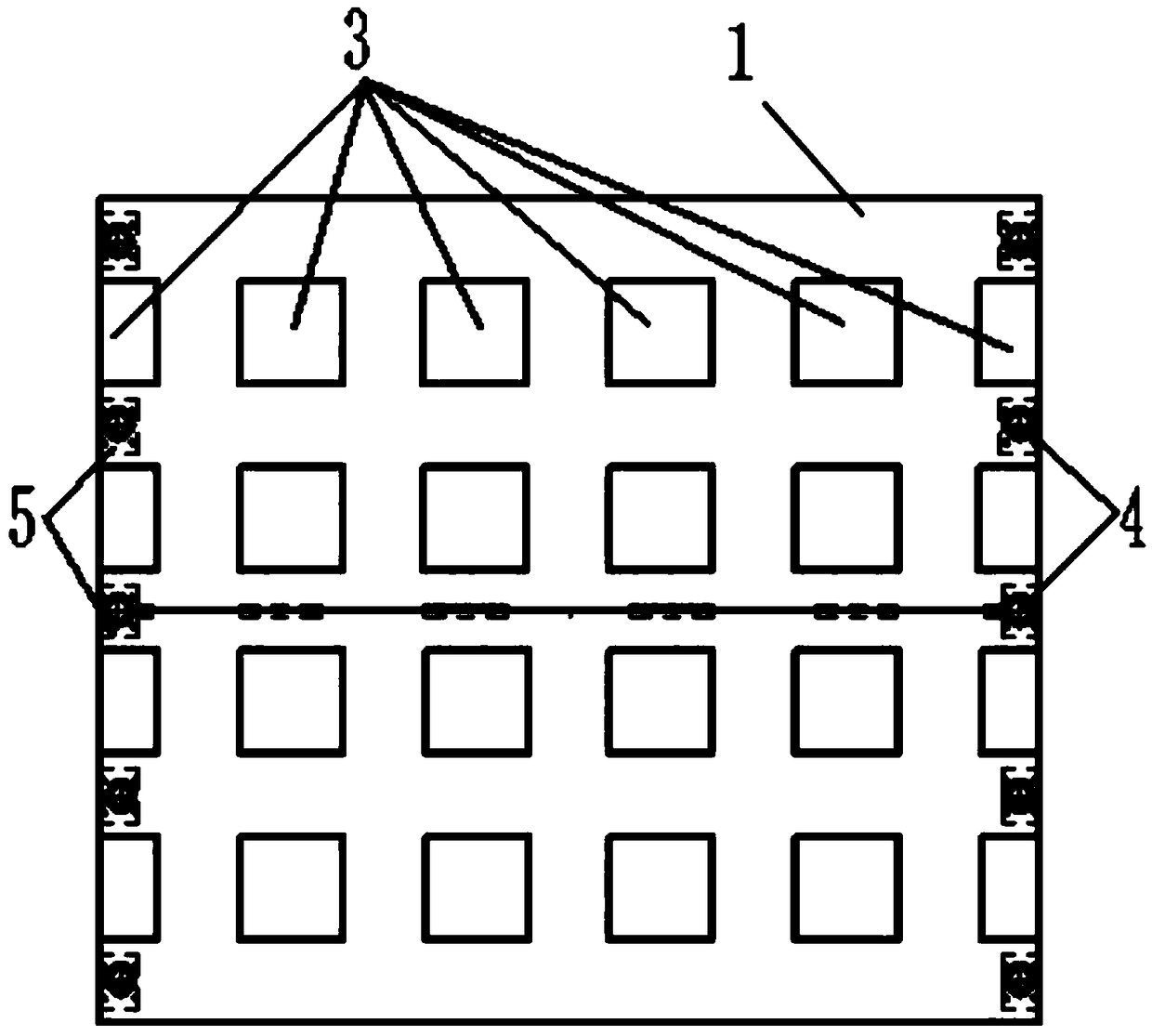

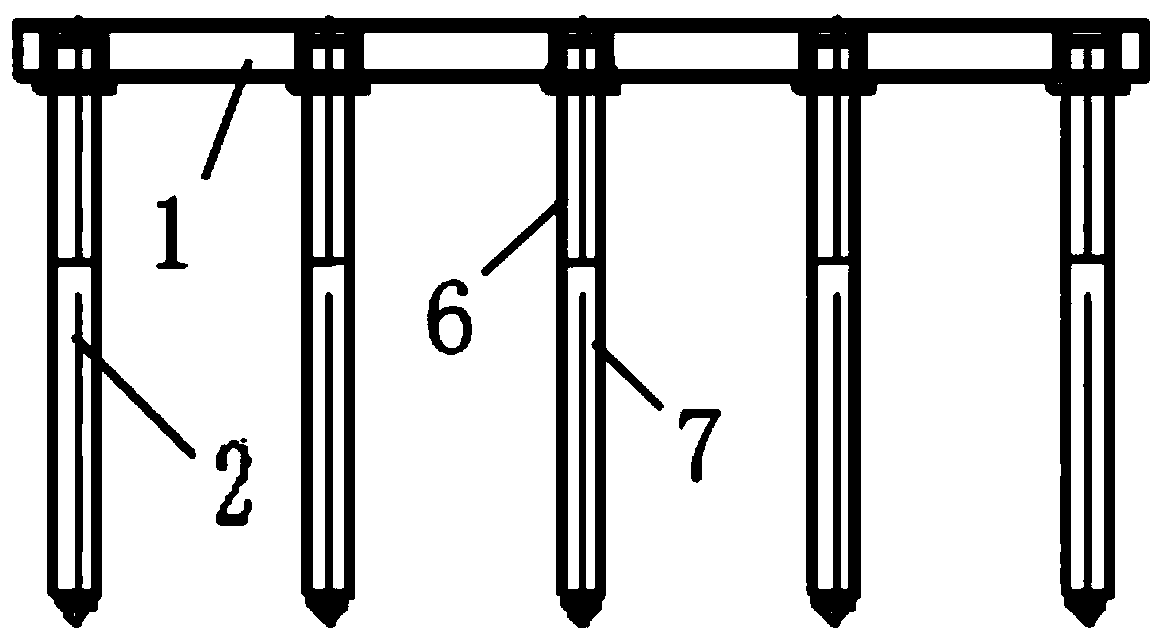

[0050] Such as Figure 1a , Figure 1b , Figure 1c , figure 2 , image 3 , Figure 4a , Figure 4b and Figure 5 Shown is a specific implementation of the roadway excavation shield bracket of the present invention. In this embodiment, the roadway excavation shield bracket mainly includes: a shield plate girder 1 and a two-way jacking mechanism 2 .

[0051] The cover plate girder 1 is a splicing structure, and the cover plate girder 1 of the splicing structure is composed of at least two concave-convex splicing plates connected into a whole by high-strength bolts. A plurality of drilling skylights 3 are provided on the cover plate beam 1, and the anchor rod (cable) drilling equipment is drilled at the roadway top 101 through the drilling skylight 3 under the cover plate beam 1 for installing the anchor rod (cable), The quantity, position and size of the drilling skylight 3 can be reasonably selected according to the roadway support design, which can realize the simultan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com