Redundancy control type hydraulic station

A technology of redundant control and hydraulic station, which is applied in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems affecting the production sequence and the unsolved high-pressure filter pollution-holding capacity, etc., to achieve Effects of avoiding production loss or production accidents, protecting the environment, and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

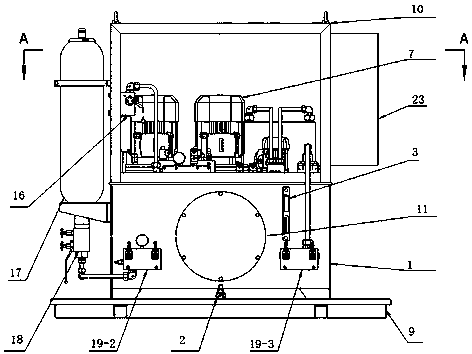

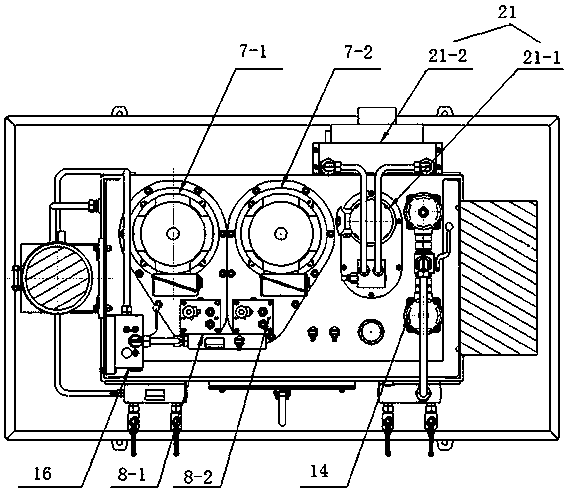

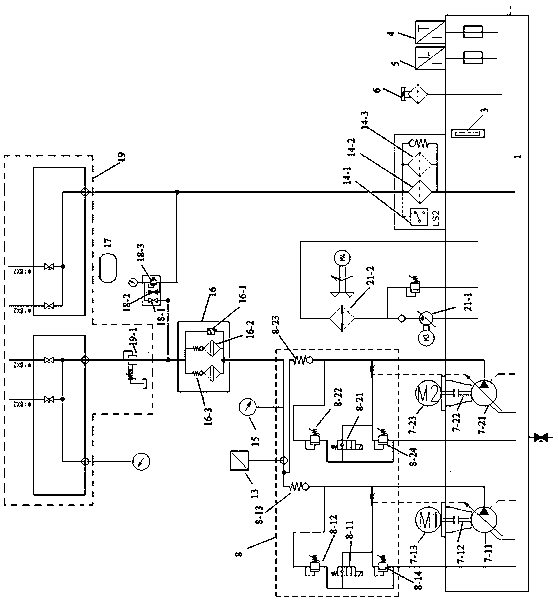

[0036] Such as Figure 1~Figure 3 As shown, the redundant control hydraulic station includes a main body of the hydraulic station, the main body of the hydraulic station includes a fuel tank 1, and two pump groups 7, a control oil circuit block 8, a pressure regulating valve group 19, High-pressure filter 16, oil return filter 14; the two pump groups 7, control oil circuit block 8, pressure regulating valve group 19, high-pressure filter 16, and oil return filter 14 are connected in sequence; the two pump groups 7 communicate with the two oil outlets of the oil tank 1 respectively, and the oil return filter 14 communicates with the oil return port of the oil tank 1 . The control oil circuit block 8 includes two parallel control oil circuit blocks 8, and the two control oil circuit blocks 8 are respectively connected with two parallel pump sets 7, and the high pressure filter 16 includes a high pressure filter switching valve 16-1 and the first high-pressure filter 16-2 and th...

Embodiment 2

[0047] This embodiment is improved on the basis of Embodiment 1. The improvement is that: the oil return filter 14 includes an oil return filter switching valve 14-1 and a valve connected to the oil return filter switching valve 14-1. The first oil return filter 14-2 and the second oil return filter 14-3; the first oil return filter 14-2 and the second oil return filter 14-3 are connected in parallel, and the first oil return filter The oil outlets of the filter 14-2 and the second oil return filter 14-3 communicate with the oil return port of the mailbox respectively.

[0048] The switching valve of the oil return filter 14 is integrated with the oil return filter 14, and the switching valve of the oil return filter 14 includes two valve positions, corresponding to the first oil return filter 14 and the second oil return filter respectively 14. When the valve position is switched, the switching of the first oil return filter 14 and the second oil return filter 14 is completed...

Embodiment 3

[0051] This embodiment is improved on the basis of Embodiment 1 or 2, and the improvement is that: the hydraulic station also includes an accumulator 17 and an accumulator control oil circuit block 818 connected to the accumulator 17, so The accumulator control oil block 818 includes a first cut-off valve 18-1, a second cut-off valve 18-2 and a first overflow valve 18-3; the first cut-off valve 18-1 and the second cut-off valve 18 -2. The first relief valve 18-3 communicates, and the second cut-off valve 18-2 and the first relief valve 18-3 are connected in parallel; the oil outlet of the high-pressure filter 16 is connected to the first cut-off valve 18-1; the accumulator 17 communicates with the second cut-off valve 18-2 and the first overflow valve 18-3. The hydraulic oil that passes through the high-pressure filter 16 enters the accumulator 17 through the accumulator control oil circuit block 818. When the power supply of the hydraulic station is cut off, the energy stored...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com