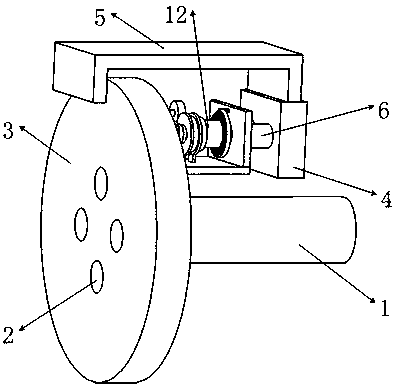

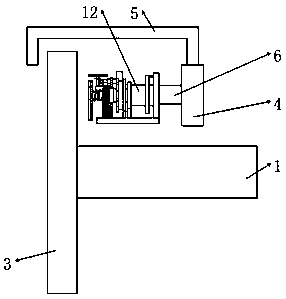

Brake mechanism for automobile

A braking mechanism, automobile technology, applied in the direction of brake actuator, gear shifting mechanism, mechanical equipment, etc., can solve the problem of automobile touching accident and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

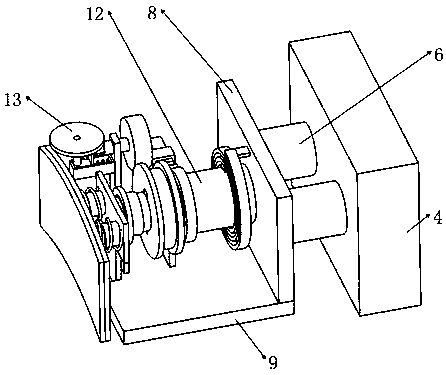

[0060] Specific embodiments: when the driver brakes, the hydraulic system on the car starts to provide hydraulic oil, so the hydraulic column 6 is extended. When the hydraulic column 6 is extended, the hydraulic column 6 pushes the first fixed plate 8 to move toward the brake disc 3 , and then the second fixed plate 9 , the power mechanism 13 and the pressing mechanism 12 move toward the brake disc 3 . The brake pad 26 in the pressure applying mechanism 12 and the contact brake of the brake disc 3 like this, the second telescopic rod 23 is slightly compressed at this moment, and the telescopic rod spring 24 is compressed, has guaranteed that there is a large gap between the brake pad 26 and the brake disc 3. pressure. The friction wheel 51 in the power mechanism 13 is squeezed into contact with the brake disc 3, and the friction wheel 51 drives the guide block 73 to move in the guide rail 65 through the rotating shaft 58, and the guide block 73 is compressed; the brake disc 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com