Extension spring type quasi-zero stiffness vibration isolator

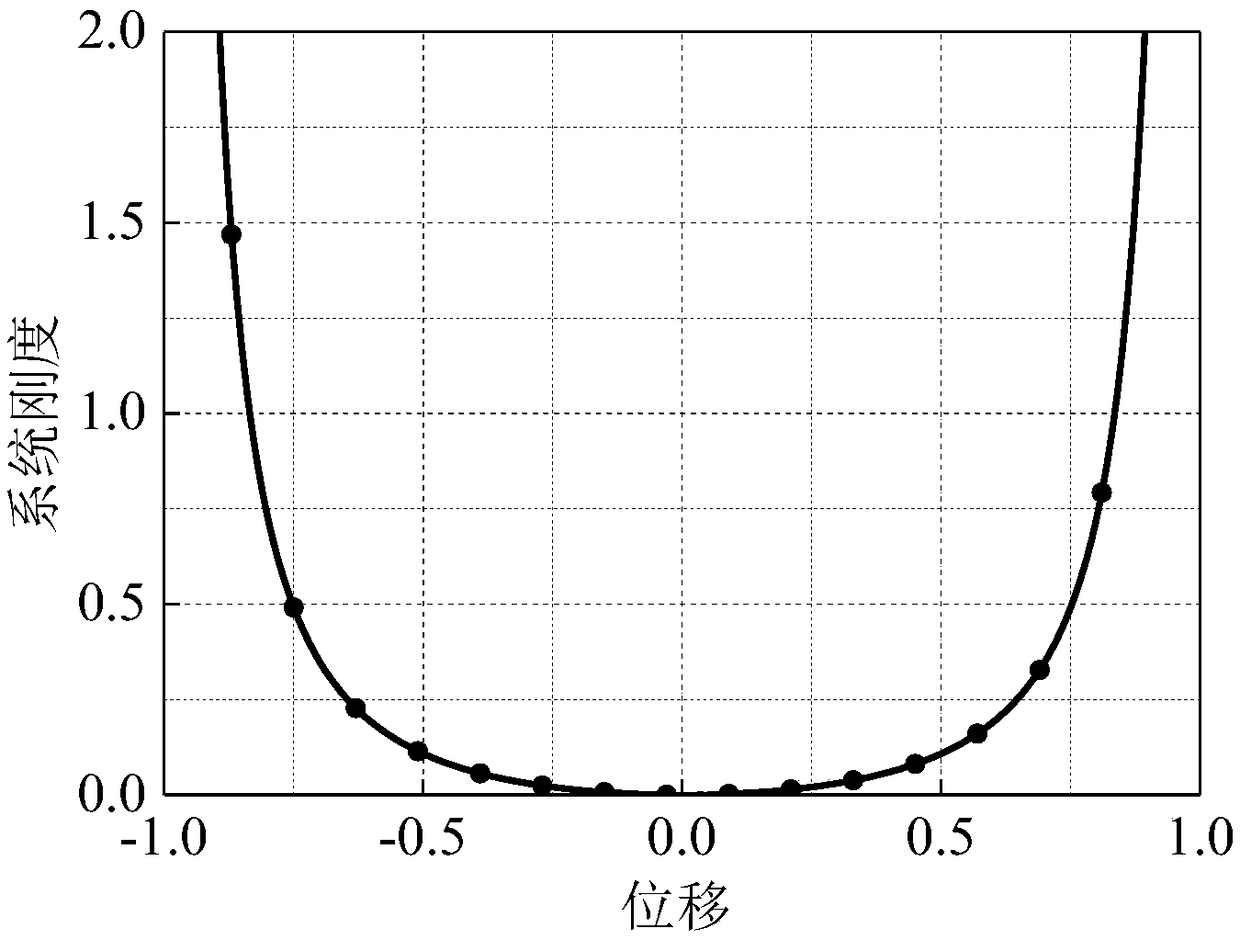

A technology of quasi-zero stiffness and tension springs, which is applied in the field of tension spring type quasi-zero stiffness vibration isolators, can solve problems such as inability to effectively isolate low-frequency vibrations between equipment and equipment foundations, reduce work efficiency of mechanical equipment, and damage mechanical equipment. , to achieve excellent vibration isolation effect, large bearing capacity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

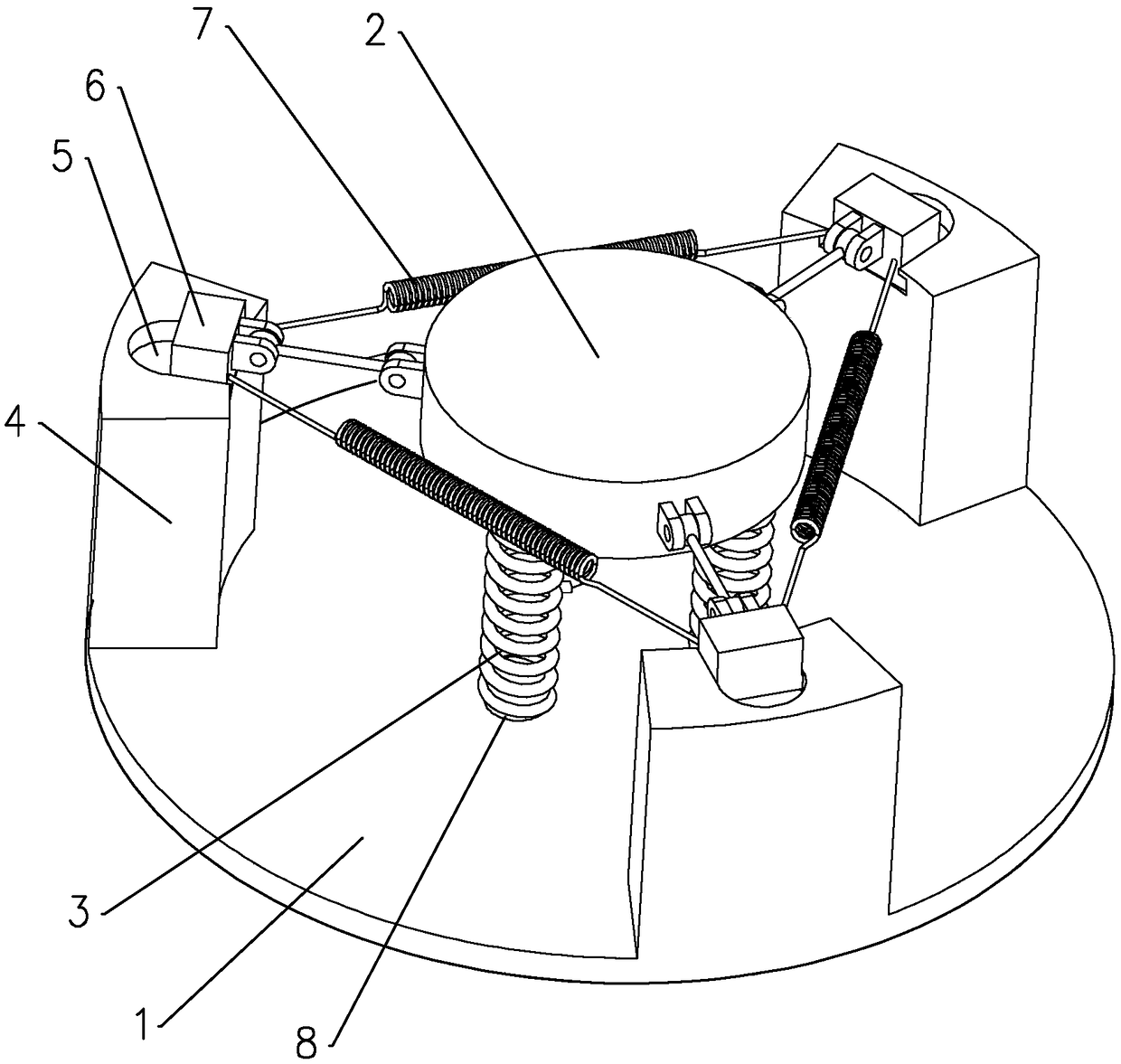

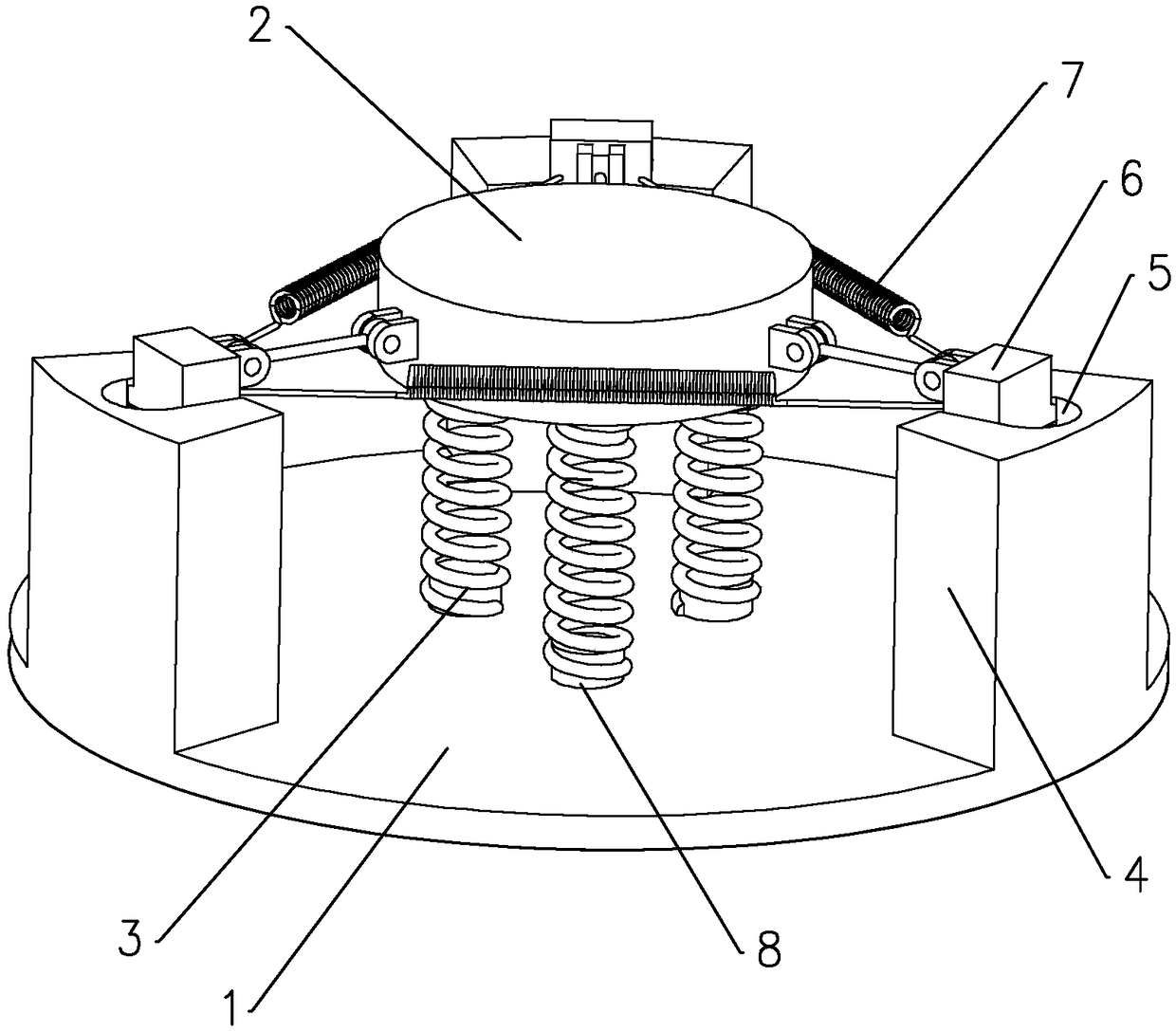

[0014] Such as figure 1 with figure 2 As shown, the tension spring type quasi-zero stiffness vibration isolator of the present invention includes a base 1, a platform 2 is provided above the middle of the base 1, and a compression spring 3 is provided along the vertical direction below the platform 2 and a compression spring 3 The upper end of the top is at the bottom of the platform 2, and the lower end of the compression spring 3 rests on the base 1. At the top of the base 1, there are more than 3 fixed support seats 4 surrounding the platform 2 with the platform 2 as the center. The bottom end of each fixed support base 4 is fixedly connected with the base 1 respectively, and the top end of each fixed support base 4 is respectively provided with a slide 5 along the radial direction, and the slide 5 penetrates the corresponding radially inward On the inner edge of the fixed support base 4, each slideway 5 is equipped with a slider 6, and the end surface of each slider 6 facin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com