Fast detection device for spatially continuous bent pipe

A detection device and pipe bending technology, which is applied in the direction of measuring device, elastic test, machine/structural component test, etc., can solve the problems of high cost, long time, low efficiency, etc., and achieve low production cost, simple operation, and guaranteed The effect of vertical relationships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

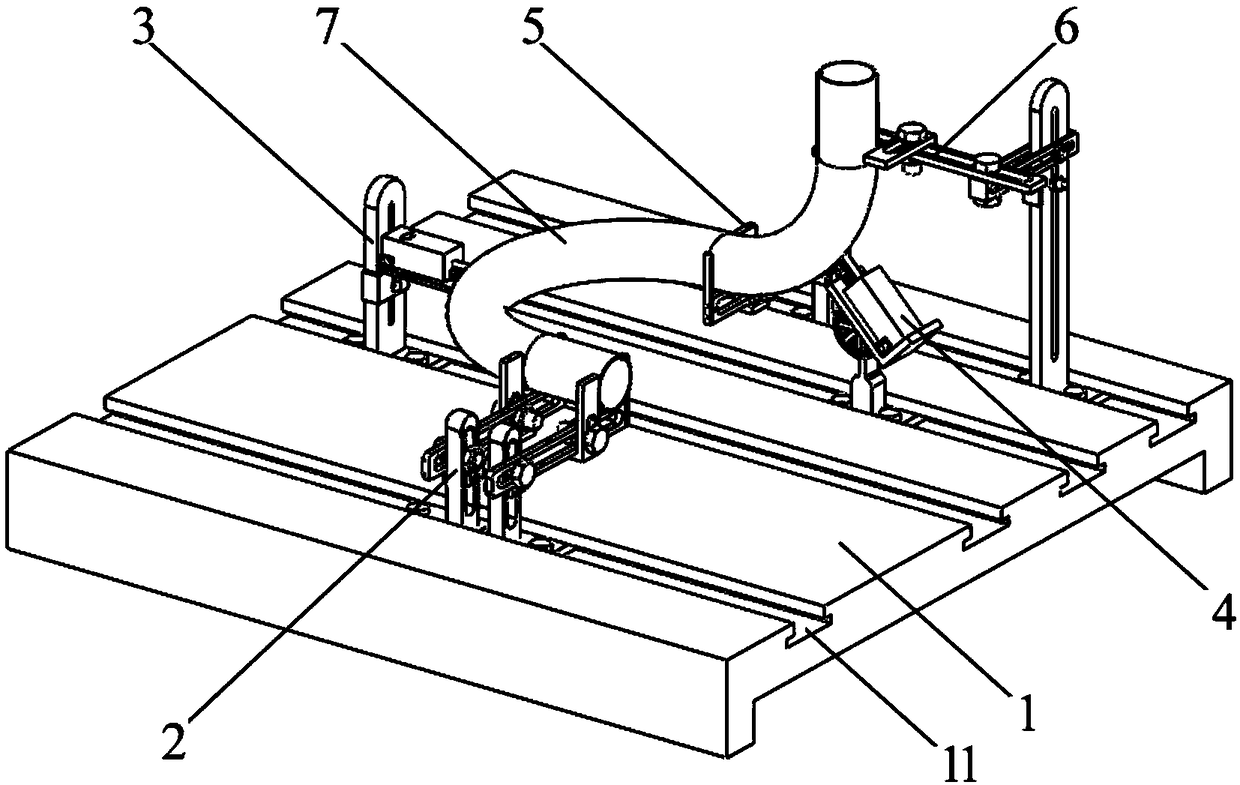

[0044] A rapid detection device for spatially continuous bent pipes in this embodiment, such as Figure 1-15 As shown, a base plate 1 is included, and the base plate 1 is equipped with a reference positioning module 2, a first ellipticity detection module 3, a second ellipticity detection module 4, a first rebound detection module 5 and a second rebound detection module 6. The reference positioning module 2 , the first ellipticity detection module 3 , the second ellipticity detection module 4 , the first rebound detection module 5 and the second rebound detection module 6 are provided with an elbow 7 .

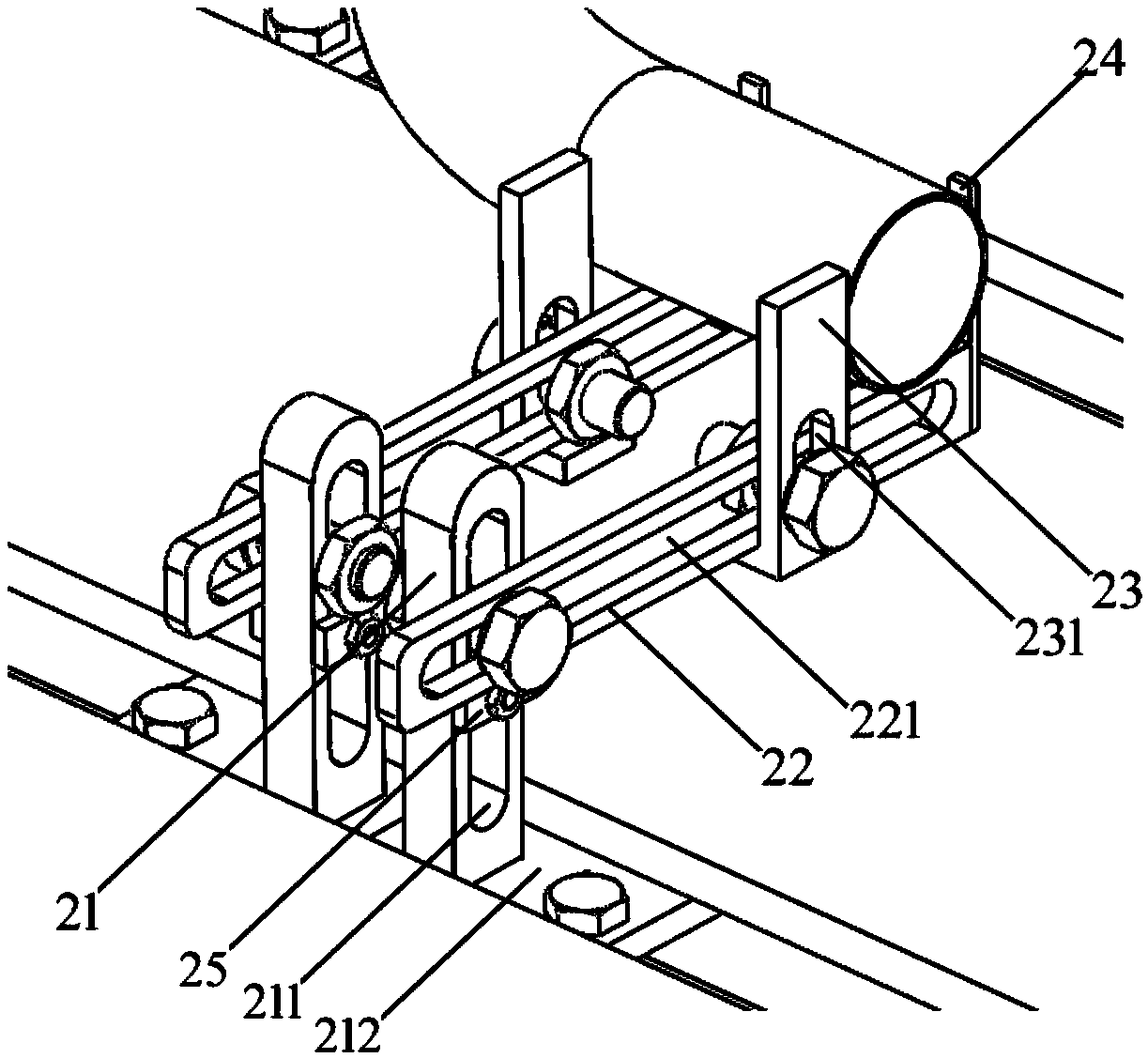

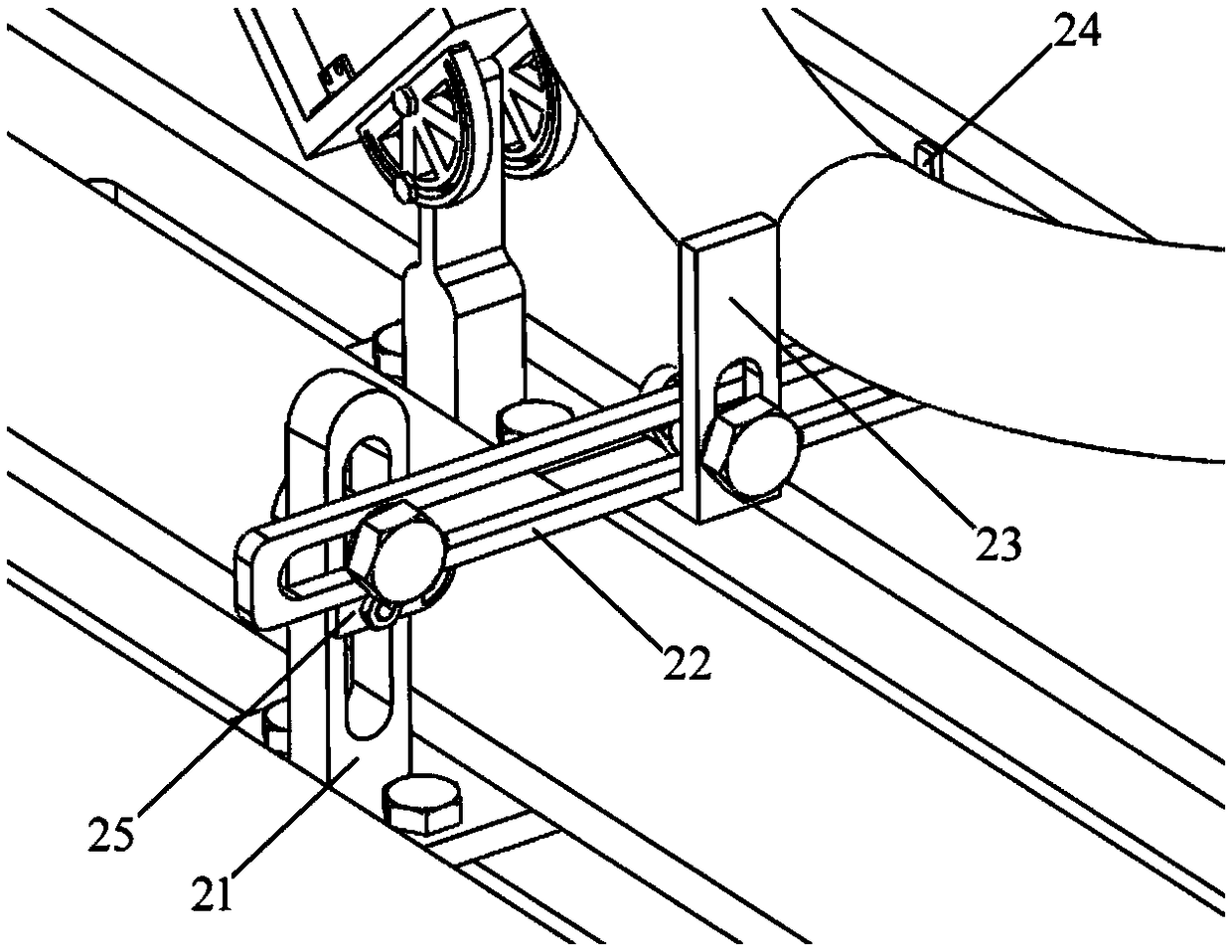

[0045] The reference positioning module 2 and the first rebound detection module 5 respectively include a vertical slide bar 21, and the vertical slide bar 21 is connected to the horizontal slide bar 22, the support frame 25, and the base plate 1 respectively; the horizontal slide bar 22 links to each other with L-shaped adjustment slide block 23, positioning plate 24 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com