A sliding type inclinometer automatic measurement and positioning structure and its use method

A technology for automatic measurement and positioning of structures, applied in the direction of measuring devices, measuring inclinations, instruments, etc., can solve the problems of difficulty in keeping the standards of reference marks consistent, difficult to ensure position consistency, and deflection of displacement sensors, etc., to achieve automatic The effect of data collection, simplification of inclinometer work and avoidance of deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

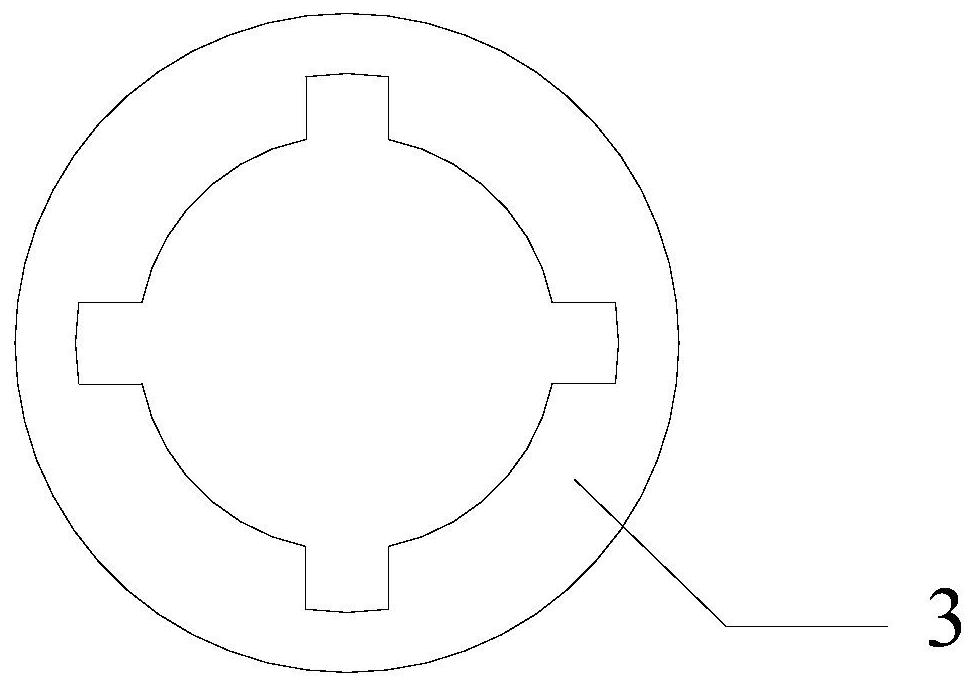

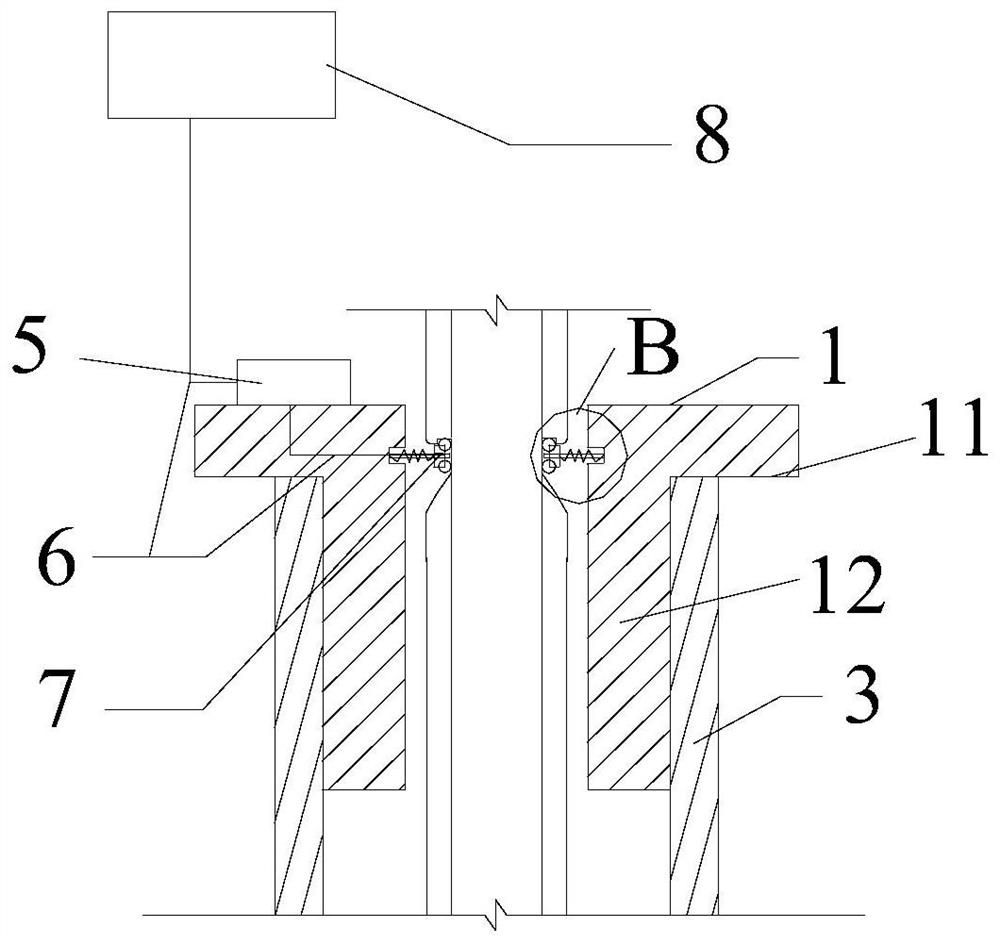

[0052] Such as Figure 3-8 As shown, a sliding inclinometer measurement positioning structure, including positioning cover 1 and cable 2;

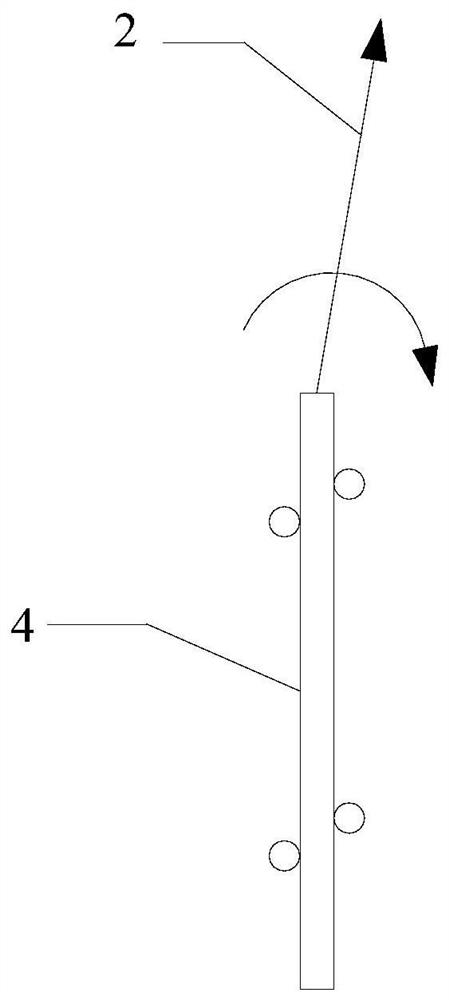

[0053] The positioning cover 1 includes a hollow cylindrical body 12 and a cover edge 11 extending outward from the top of the body 12. The body 12 and the cover edge 11 are integrally formed, and the body 11 is inserted into the nozzle of the inclinometer tube 3. The body 12 and the cover edge 11 are provided with a notch 13 that runs through the inner and outer walls at the same position, and the inner wall of the body 12 is symmetrically provided with a telescopic clamping device 1-1, and the front end of the telescopic clamping device 1-1 is provided with a Roller 1-1-5;

[0054] The first end of the cable 2 is connected to the displacement sensor 4, and the second end is connected to the reading instrument. The cable 2 is equidistantly provided with positioning grooves 21 along the first end to the second end, and the positioning gro...

Embodiment 2

[0068] See attached Figure 3-10 , embodiment 2 is the using method of embodiment 1, comprises the steps:

[0069] (1) Provide a sliding inclinometer with the aforementioned cable 2 and the aforementioned positioning cover 1;

[0070] (2) Open the protective cover of the inclinometer tube, and slowly put the displacement sensor 4 into the bottom of the inclinometer tube 3 through the cable 2;

[0071] (3) Put the cable into the middle of the positioning cover 1 through the gap 13, and put the slide bar 1-1-2 of the telescopic clamping device 1-1 on both sides into the chute 22 of the cable 2 , and then, insert the positioning cover 1 in the nozzle of the inclinometer tube 3, and ensure that the top of the inclinometer tube 3 is attached to the bottom of the cover edge 11;

[0072] (4) Pull the cable so that the telescopic clamping device 1-1 stretches out and snaps into the first positioning groove 21, and then loosens the cable 2. At this time, the slider 1-1-4 triggers the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com