Non-contact measuring method for axial and radial deformation quantities of explosive columns under temperature loading condition

An axial deformation and non-contact technology, applied in measuring devices, fuel testing, instruments, etc., can solve the problems of unreal-time detection of dimensional changes, potential safety hazards, large errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

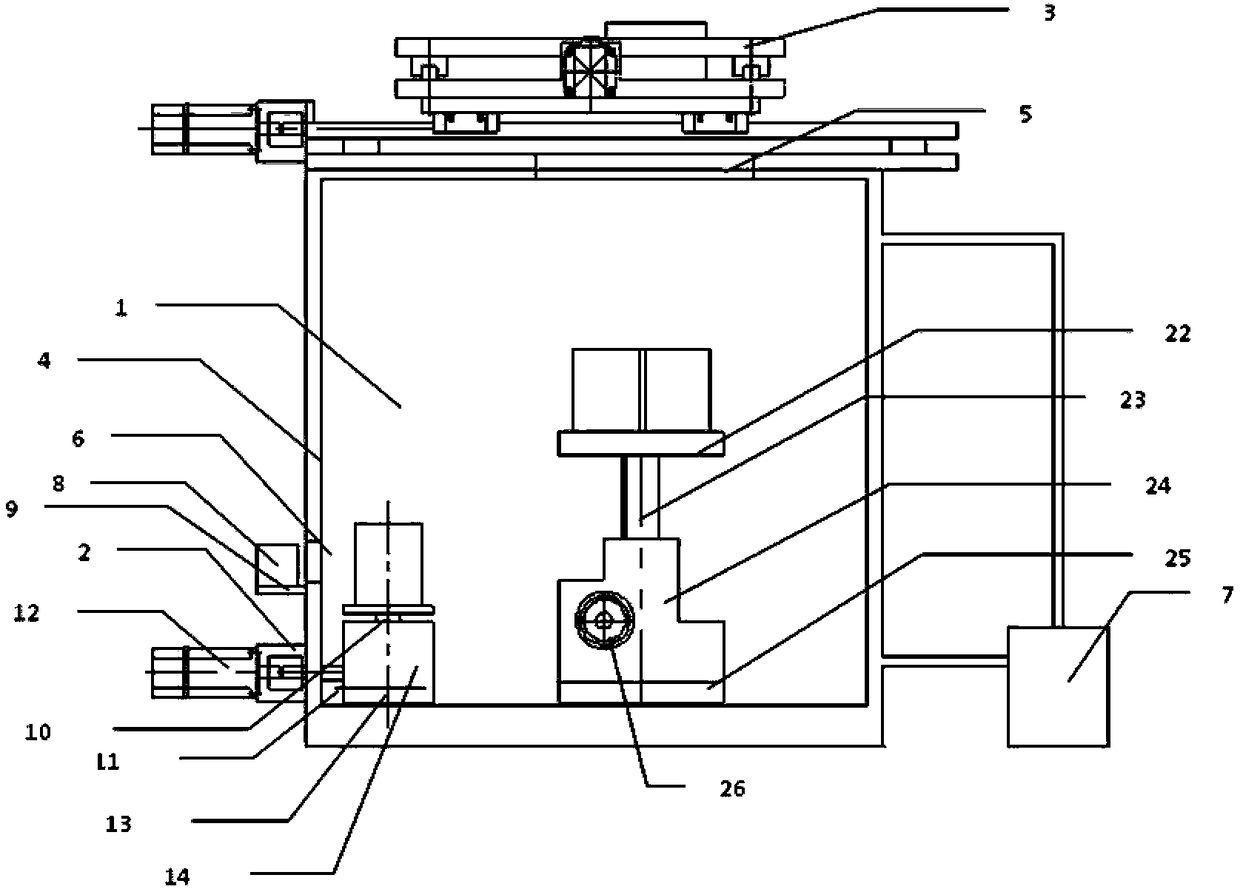

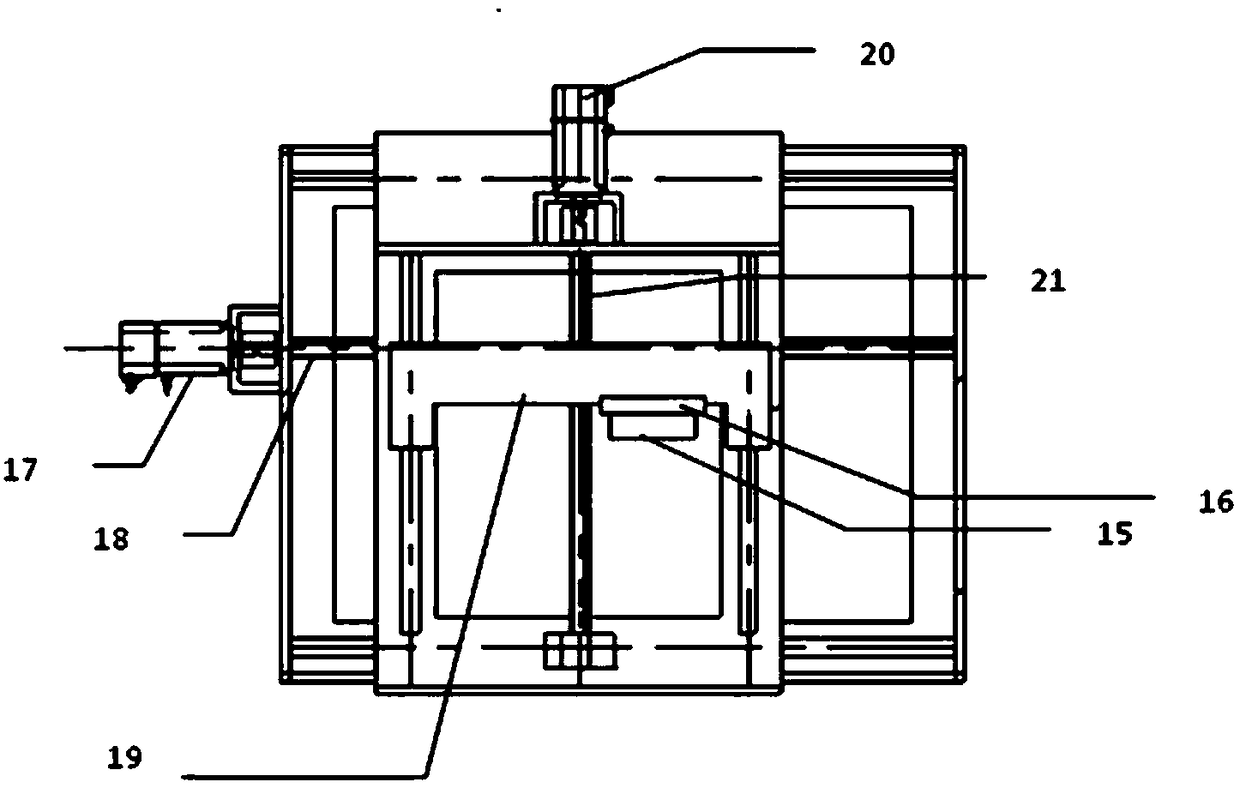

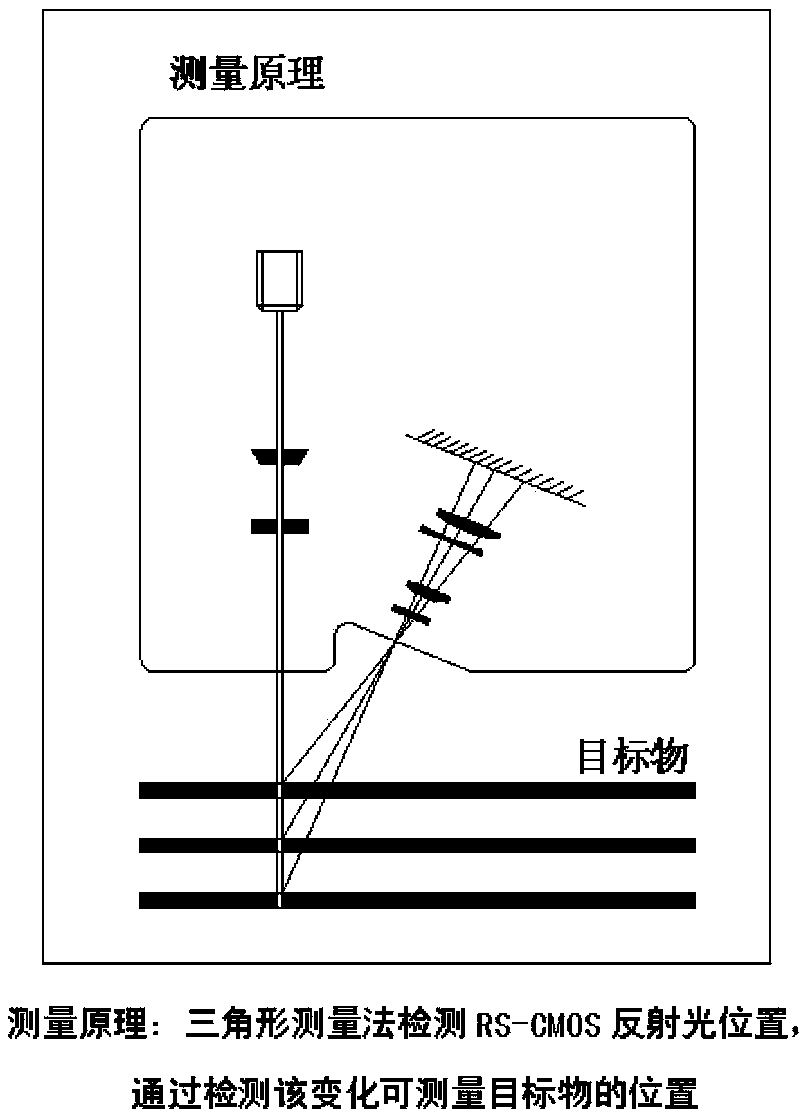

[0042] The non-contact method for measuring the axial and radial deformation of an explosive column under temperature loading conditions, the test device includes a temperature loading unit 1, a distance measuring unit 2 for the radial deformation of the explosive column, and a distance measuring unit for the axial deformation of the explosive column Unit 3; temperature loading unit 1 includes an explosion-proof high and low temperature environment test chamber 4, a top test window 5, a side test window 6, and a refrigeration system 7; the top test window 5 is located above the explosion-proof high and low temperature environment test chamber 4 and is used for laser sensors The transmission of the light source; the side test window 6 is located at the bottom of the left middle of the explosion-proof high and low temperature environment test chamber 4, and is used for the transmission of the light source of the laser sensor; the cooling system 7 and the explosion-proof high and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap