A design and optimization method of porous structure based on three-period minimal surface

A technology with extremely small curved surface and porous structure, which is applied in the fields of engineering lightweight design, computer-aided design, medical application design and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

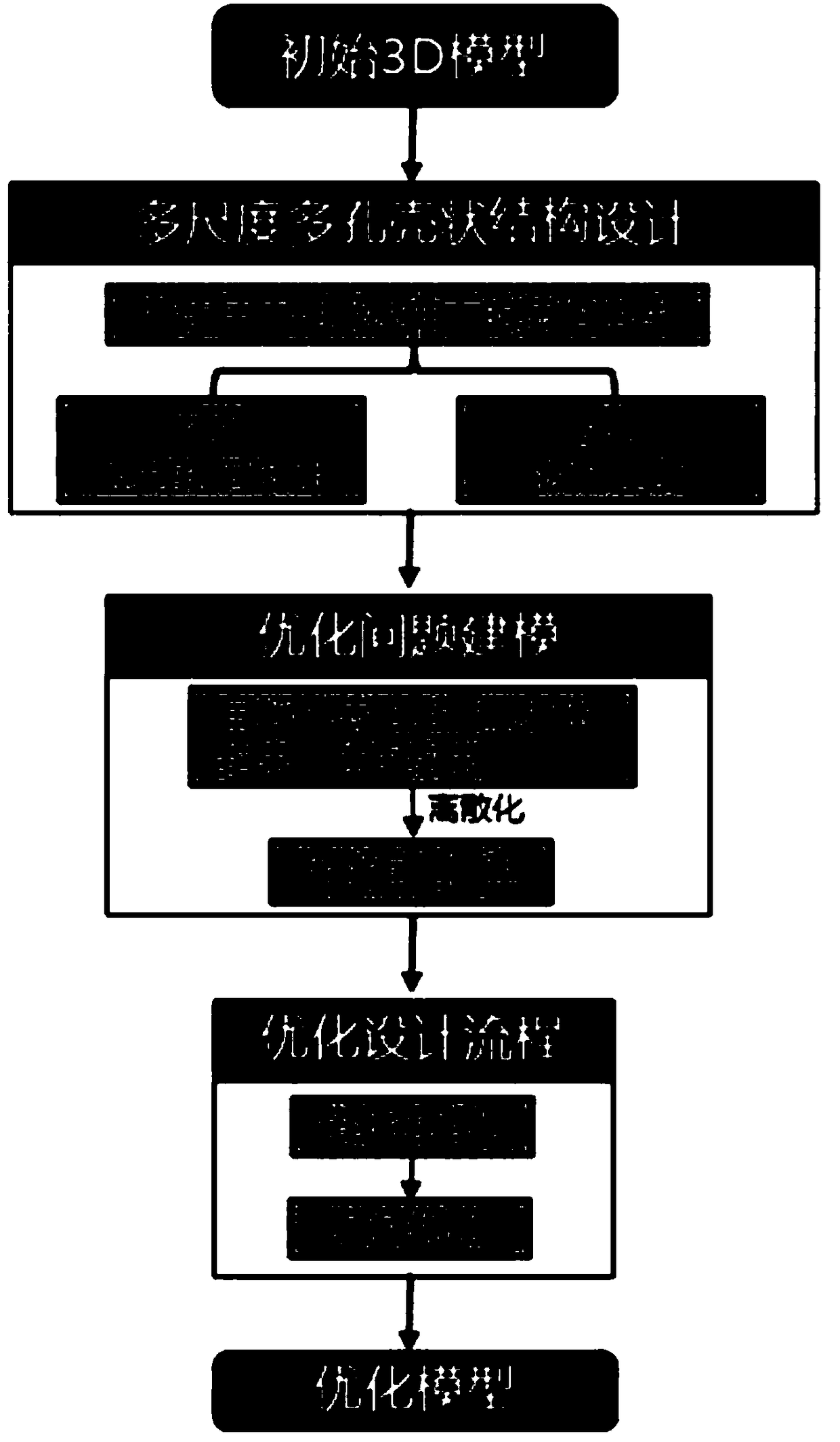

[0056] The implementation of the present invention can be divided into several main steps such as multi-scale porous shell structure design, establishment of optimization problem and its discretization, and optimization of design process:

[0057] (1) Multiscale porous shell-like structure

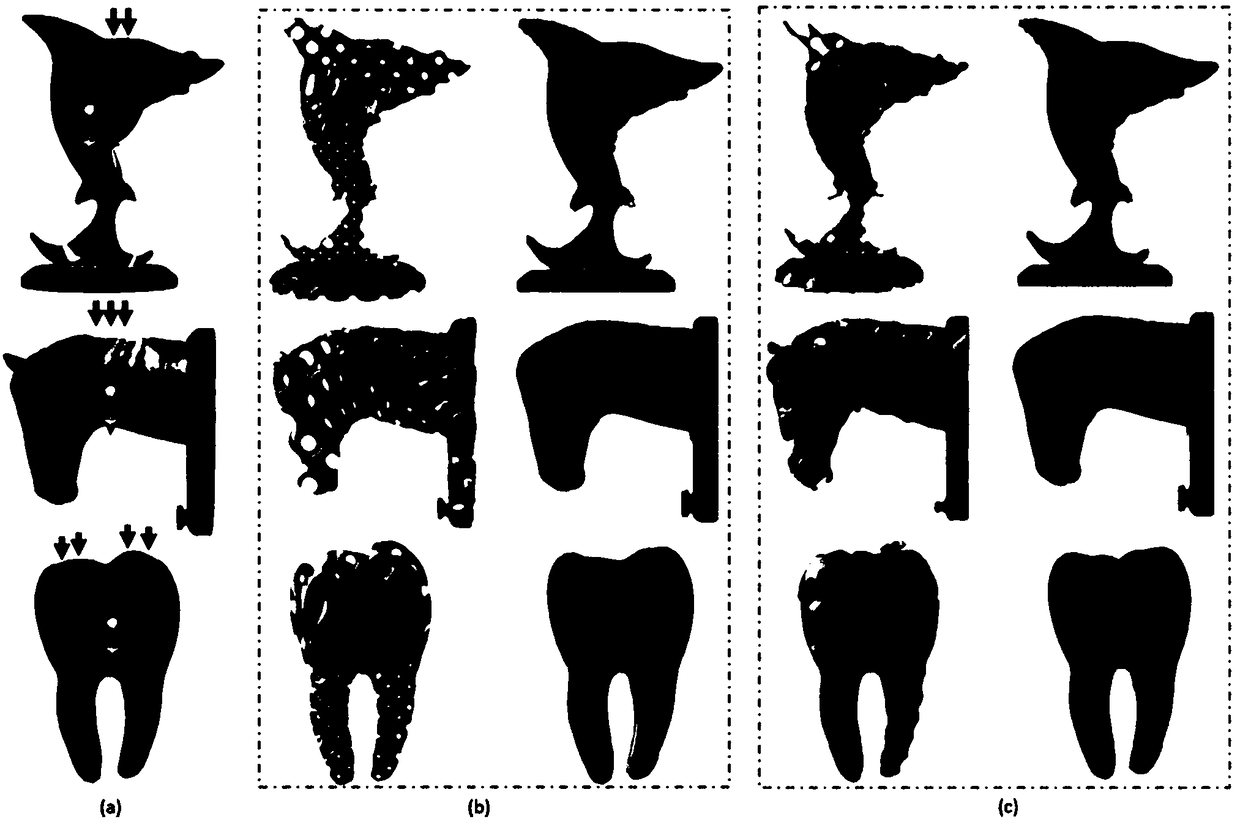

[0058] Here, with φ P (p) Curved surface as an example to illustrate the construction of multiscale porous shell-like structures. First create a multiscale porous surface:

[0059]

[0060] Among them, r is the midpoint of the three-dimensional space, c is a scalar (the value range is [-1, 1]), and t(r) controls the continuous change of the hole period (the value range is [0.5, 2]).

[0061] Furthermore, construct a multi-scale porous shell-like structure with thickness: use the closed area determined by two different isosurfaces with the same periodic distribution as the porous shell-like internal space, that is, define:

[0062]

[0063]

[0064] Then the porous shell-like st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com