High-efficiency low temperature difference integrated liquid-cooled battery system

A liquid-cooled battery and low-temperature technology, which is applied to secondary batteries, battery/fuel cell control devices, circuits, etc., can solve the problems of large temperature differences of battery cores, heat consumption, long circulating water path, etc., and improve charge and discharge performance and service life, slowing down differential changes, and reducing the effect of temperature variance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

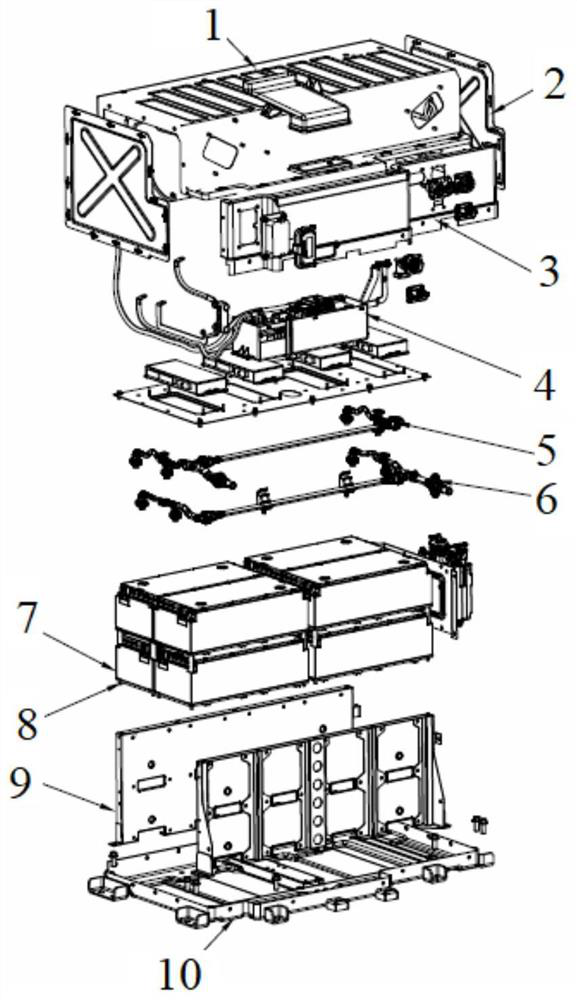

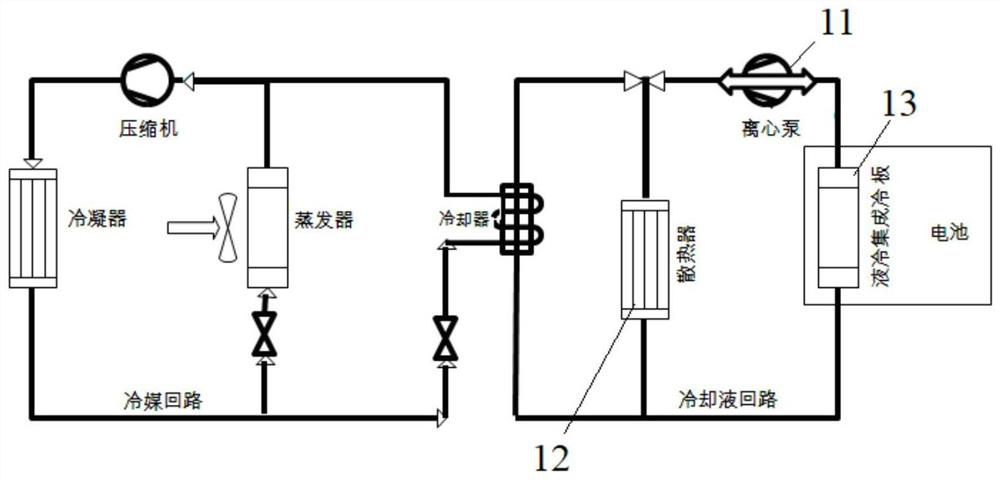

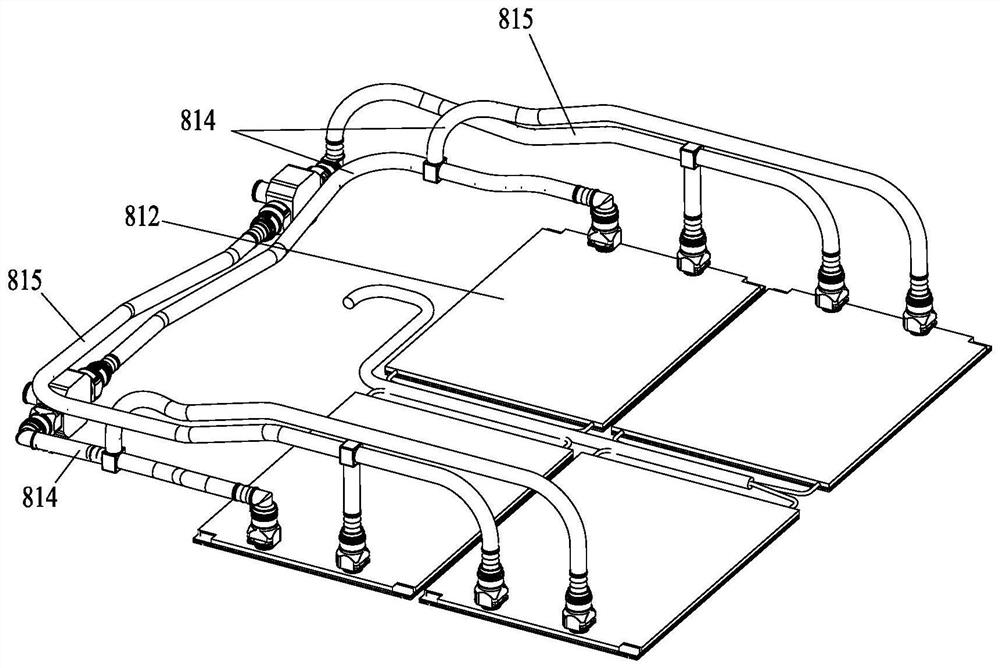

[0025] Such as Figure 1 to Figure 3 As shown, the present invention provides a high-efficiency low-temperature difference integrated liquid-cooled battery system, which includes a housing, a battery module set in the housing, a radiator 13, a liquid cooling battery set in the housing and in contact with the battery module. The cooling integrated device 8 and the circulation pump 11 connected with the liquid cooling integrated device 8 and used to change the flow direction of the cooling liquid flowing in the liquid cooling integrated device 8 .

[0026] Specifically, as figure 1 and figure 2 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap