Vacuum tube flying train communication system directly covering the leaky wave system with electromagnetic medium

A vacuum tube and leaky wave technology, applied in the field of electromagnetic waves, can solve the problems of inconspicuous advantages in the structure of vehicle-mounted relay stations and large radio wave loss, and achieve the effect of improving the quality of wireless signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

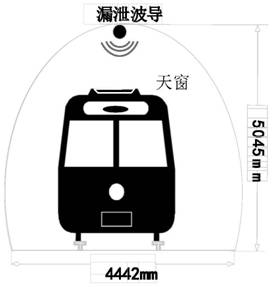

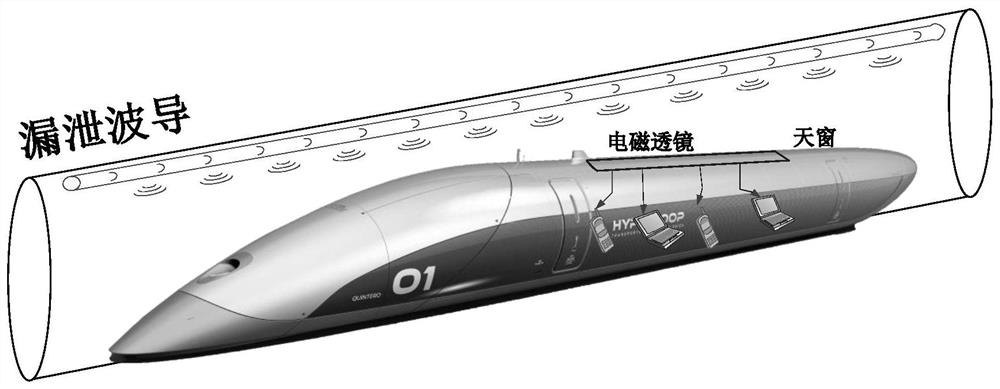

[0024] figure 1 A front view of a vacuum tube flying train communication system with an electromagnetic medium directly covering a leaky wave system provided by an embodiment of the present invention; figure 2 It is a side view of a vacuum tube flying train communication system directly covering a leaky wave system provided by an embodiment of the present invention. refer to figure 1 and figure 2 , the system includes: a leaky wave device and an electromagnetic lens.

[0025] The wave leakage device is installed on the upper side of the inner wall of the vacuum tube flying train, cuts the inner wall vertically at the point where the current density is maximum, adopts the form of wide-side transverse slits, and adopts vertical polarization to emit radio waves. It can improve the radiation capability of the slot, get better radiation performance, and make the signal strength above the waveguide meet the sensitivity requirements of the receiving antenna

[0026] As a skylig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com