Rubber composition and tire

A rubber composition and rubber technology, applied in special tires, tire parts, tire treads/tread patterns, etc., can solve problems such as tire fuel efficiency degradation, and achieve the effect of improving wet road performance and improving wet road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0089] Hereinafter, the present disclosure is described in detail with reference to Examples; however, the present disclosure is not limited to the following Examples at all.

[0090]

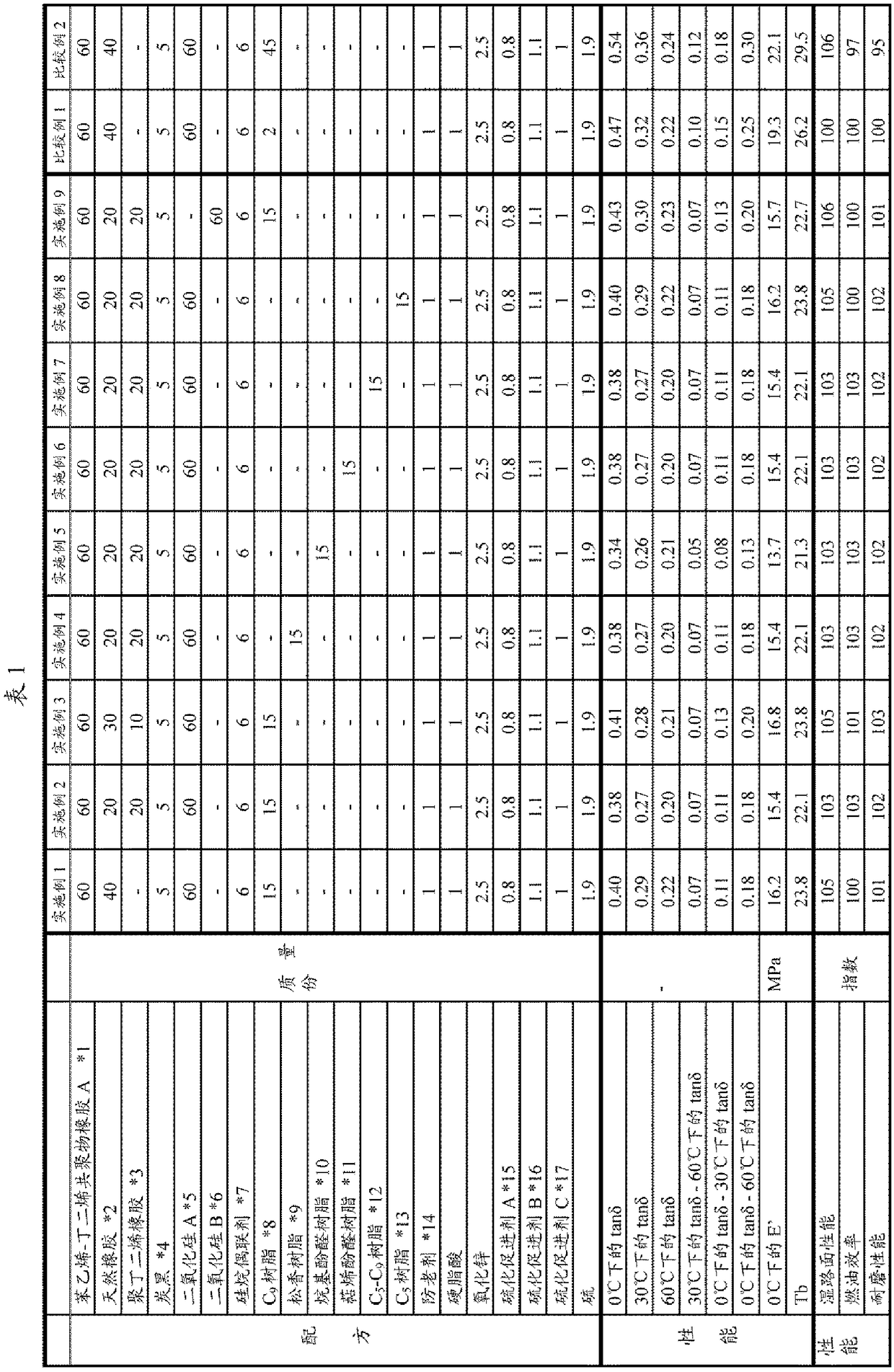

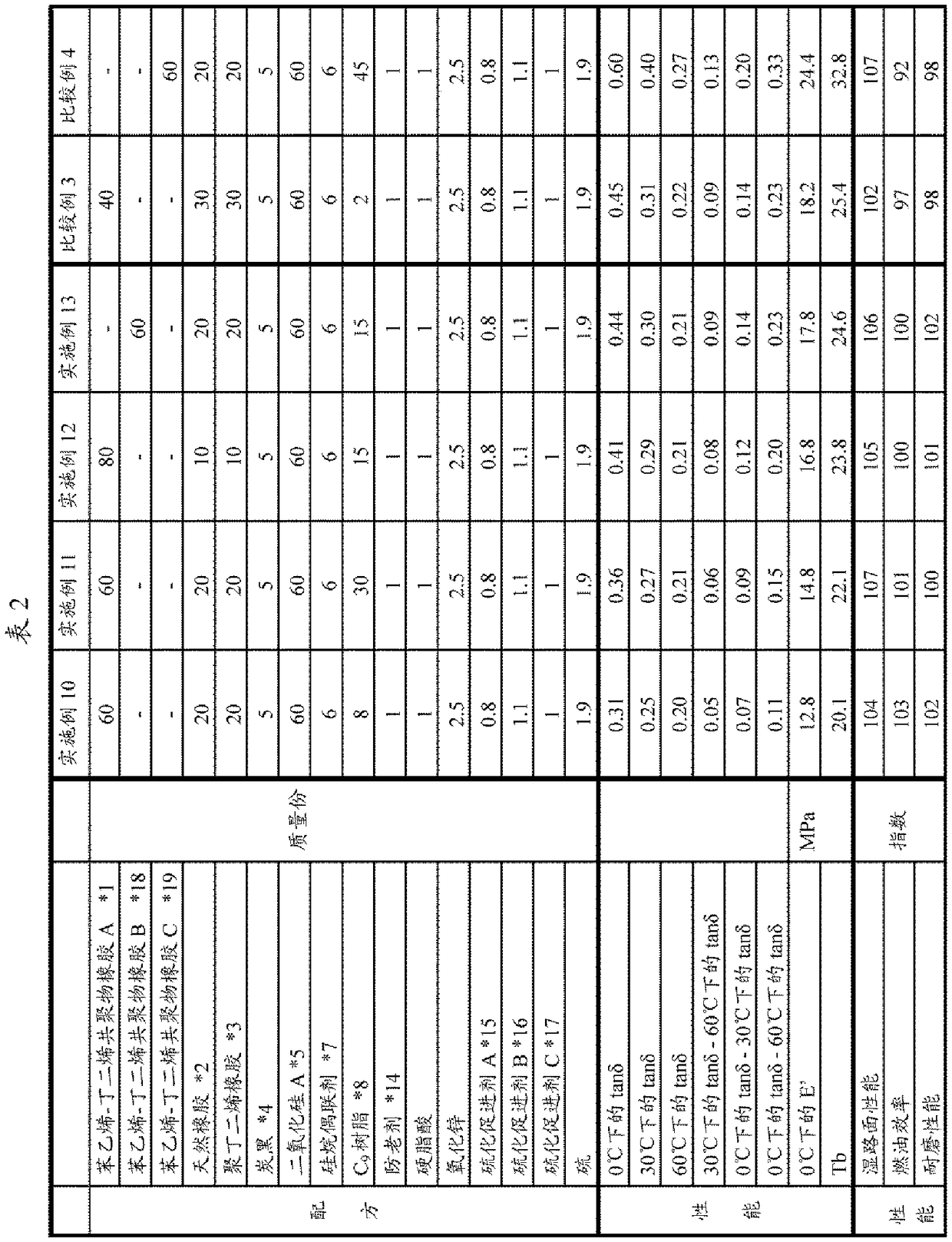

[0091] By using a general-purpose Banbury internal mixer, kneading the components other than the vulcanization compounding agent including sulfur, a vulcanization accelerator, and zinc oxide at a maximum temperature of 160° C., adding the vulcanization compounding agent to the resulting kneaded product and They were further kneaded at a maximum temperature of 110° C. to prepare rubber compositions according to the formulations in Table 1 to Table 2 . The rubber composition thus obtained was measured by the following methods of loss tangent (tan δ), storage modulus (E'), and tensile strength (Tb), and was further evaluated for wet road performance, fuel efficiency, and abrasion resistance . The results are shown in Tables 1 to 2.

[0092] (1) Loss tangent (tanδ) and storage modulus (E')

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com