Pneumatic radial tire for passenger vehicle

A technology for radial tires and passenger cars, applied to the reinforcement layer of pneumatic tires, special tires, tire parts, etc., can solve the problems of increased tire weight and air resistance, reduced rolling resistance, high vehicle resistance, etc., to achieve Effects of improving wet road performance and rolling resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

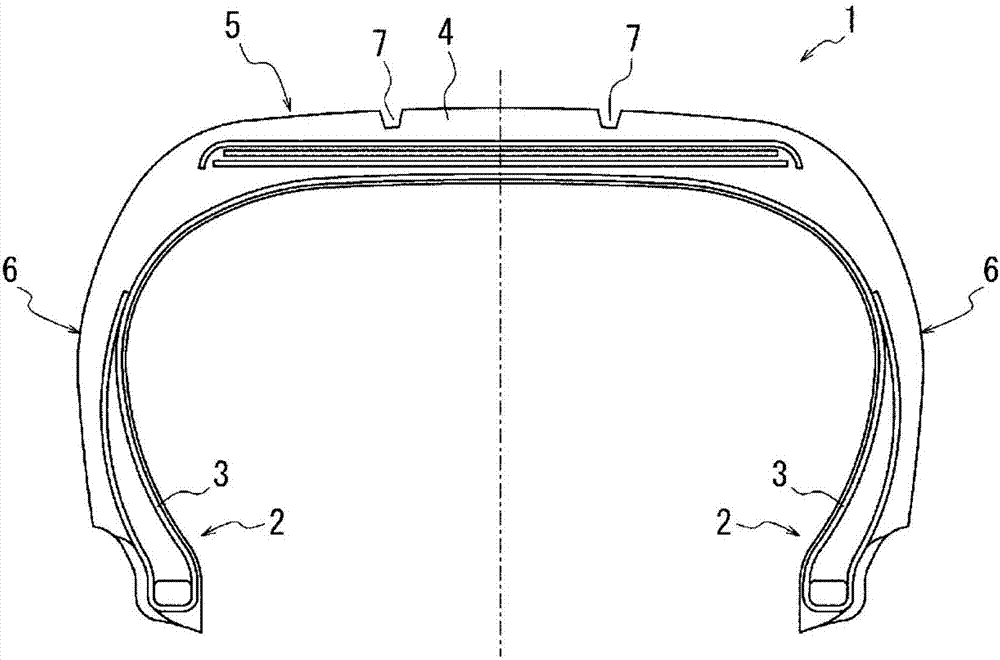

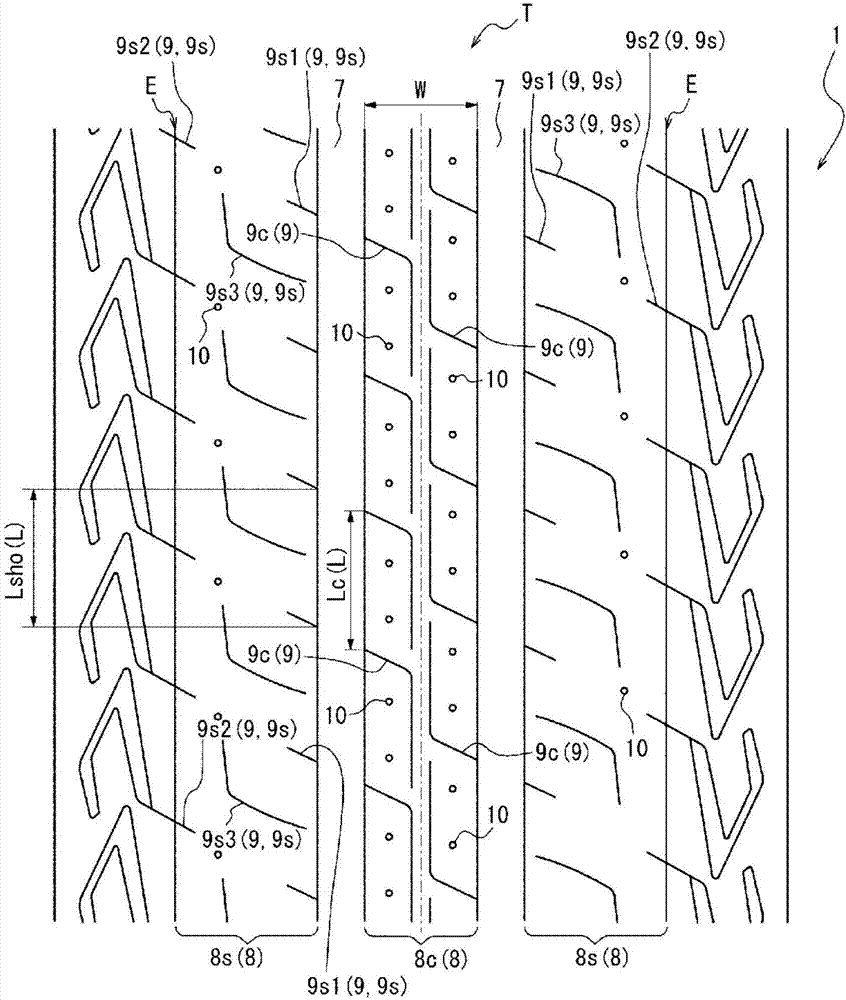

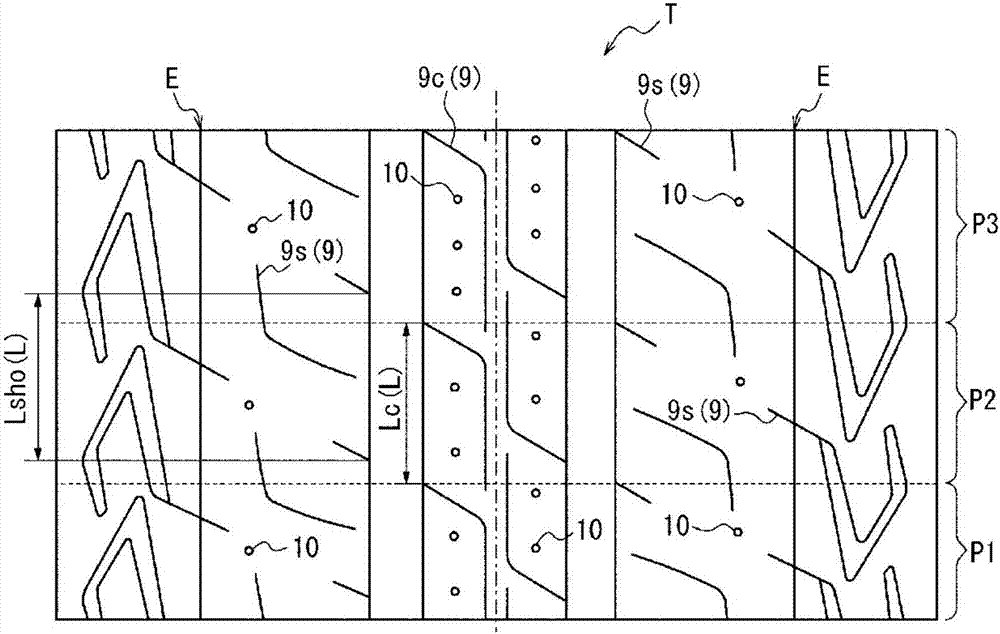

[0115] The tire of embodiment 1 is such as figure 1 with figure 2 Tire size shown is for a 165 / 60R19 tire. This tire had the specifications shown in Table 1, and was provided in the tread surface T with two circumferential main grooves. In the tire of Example 1, in the central land portion divided by these two circumferential main grooves, a plurality of sipes (central sipes) are arranged at a predetermined pitch length L measured in the tire circumferential direction, and the land portion The width W (mm) of the land portion of the land portion, the total length Ws (mm) of the sipe components in the tire width direction of the sipe arranged within the range of one pitch length L in the land portion, the pitch length L (mm), and the The tire circumferential sipe component total length Ls (mm) of sipes arranged within a range of one pitch length L in the land portion satisfies the relationships 0.4W≤Ws≤1.2W and 0.6L≤Ls≤3L. In the tire of Example 1, the average pitch length ...

Embodiment 2 to Embodiment 6

[0117] The tires of Examples 2 to 6 were the same as the tires of Example 1 except that the specifications were changed as shown in Table 1 and small holes were provided.

Embodiment 1 to Embodiment 6

[0127] Example 1 to Example 6, Comparative Examples 3 to 4: rim size 5.5J-19, internal pressure 300kPa

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com