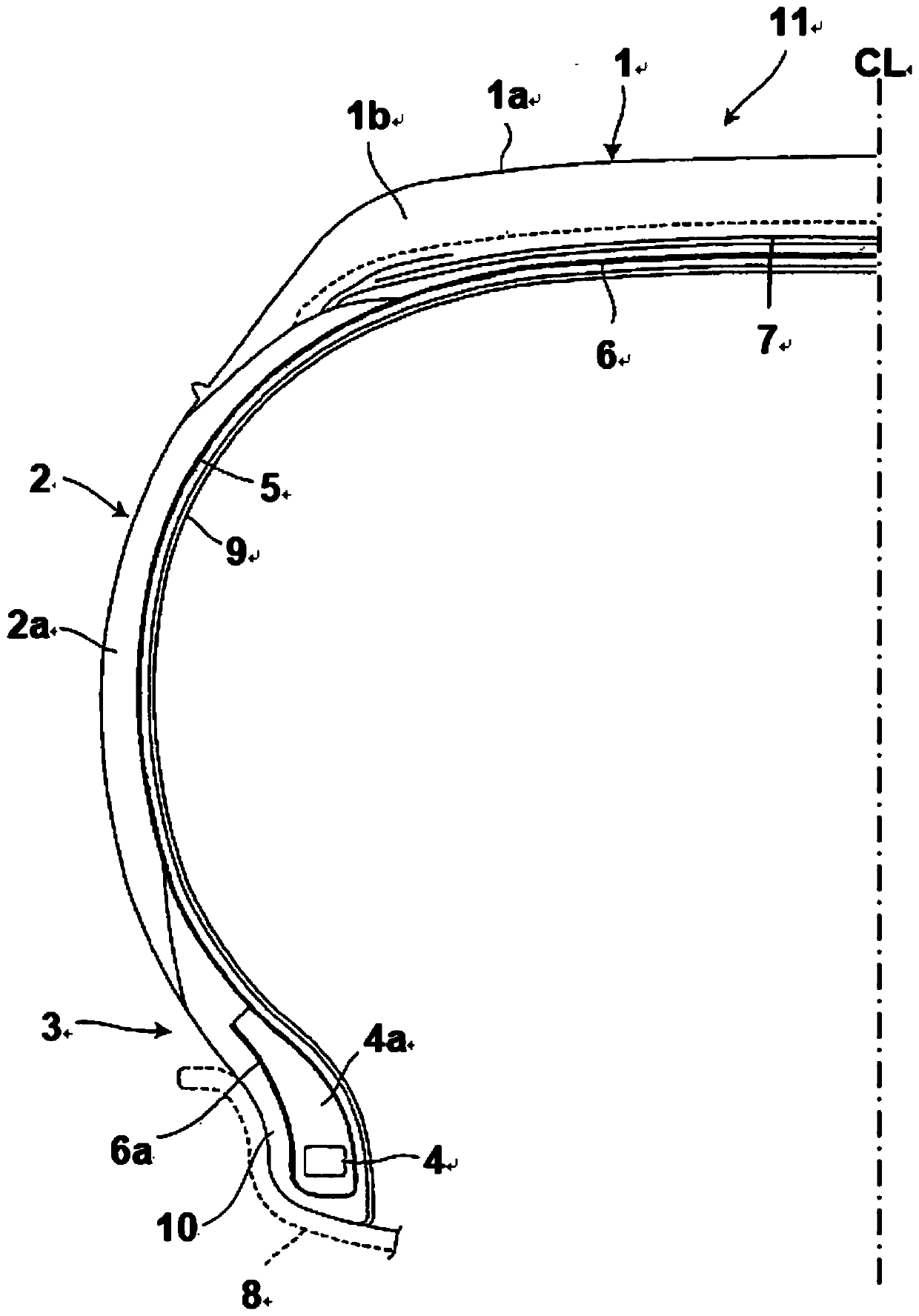

Pneumatic tire

A technology of pneumatic tires and tires, which is applied to the reinforcement layer of pneumatic tires, special tires, tire parts, etc., can solve the problems of reduced wet road grip and extended braking distance, etc. The effect of road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

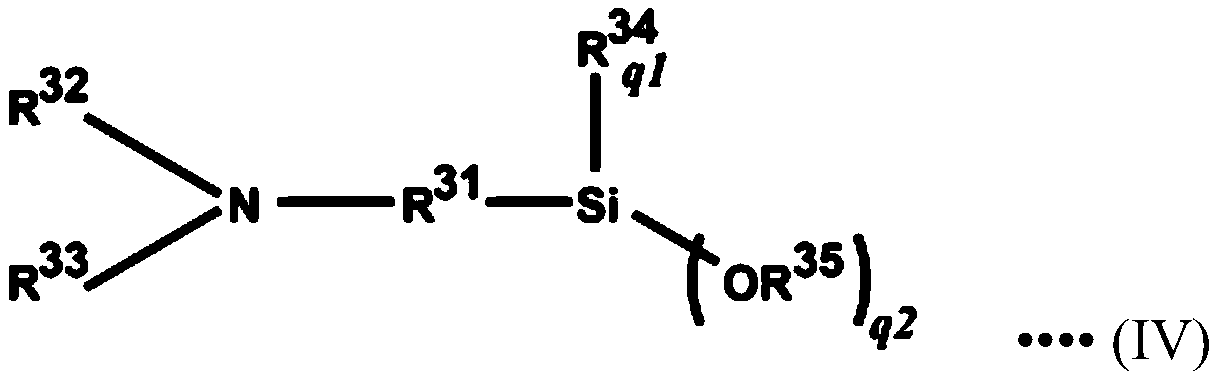

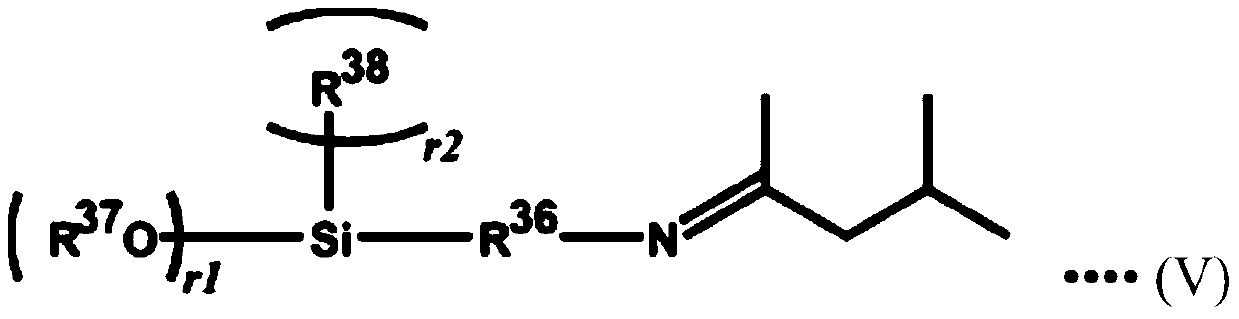

Method used

Image

Examples

manufacture example 1

[0142] [Production Example 1: Production of Modified Styrene-Butadiene Copolymer Rubber]

[0143] To a dry and nitrogen-purged 800-mL pressure-resistant glass vessel, 1,3-butadiene in cyclohexane and styrene in cyclohexane were added to contain 67.5 g of 1,3-butadiene and 7.5 g of styrene. Then, 0.6 mmol of 2,2-ditetrahydrofurylpropane was added, 0.8 mmol of n-butyllithium was further added as a polymerization initiator, and then polymerization was performed at 50° C. for 1.5 hours. The polymerization conversion in the reaction was approximately up to 100%. To the polymerization reaction system, 0.72 mmol of modifier was added and allowed to react at 50° C. for 30 minutes. After that, 2 mL of a 5% by mass solution of 2,6-di-tert-butyl-p-cresol:BHT in 2-propanol was added, and the reaction was quenched. The resulting product was dried according to a conventional method, and a modified styrene-butadiene copolymer rubber was obtained.

[0144] [production of tire]

[0145] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com