Rubber composition for tires

A rubber composition and tire technology, which is applied in special tires, tire parts, rolling resistance optimization, etc., can solve problems such as easy agglomeration, lack of rubber affinity, and insufficient dispersion, and achieve improved dispersion, wet roads, etc. Adhesion performance improvement, effect of improving low rolling resistance and wet road adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

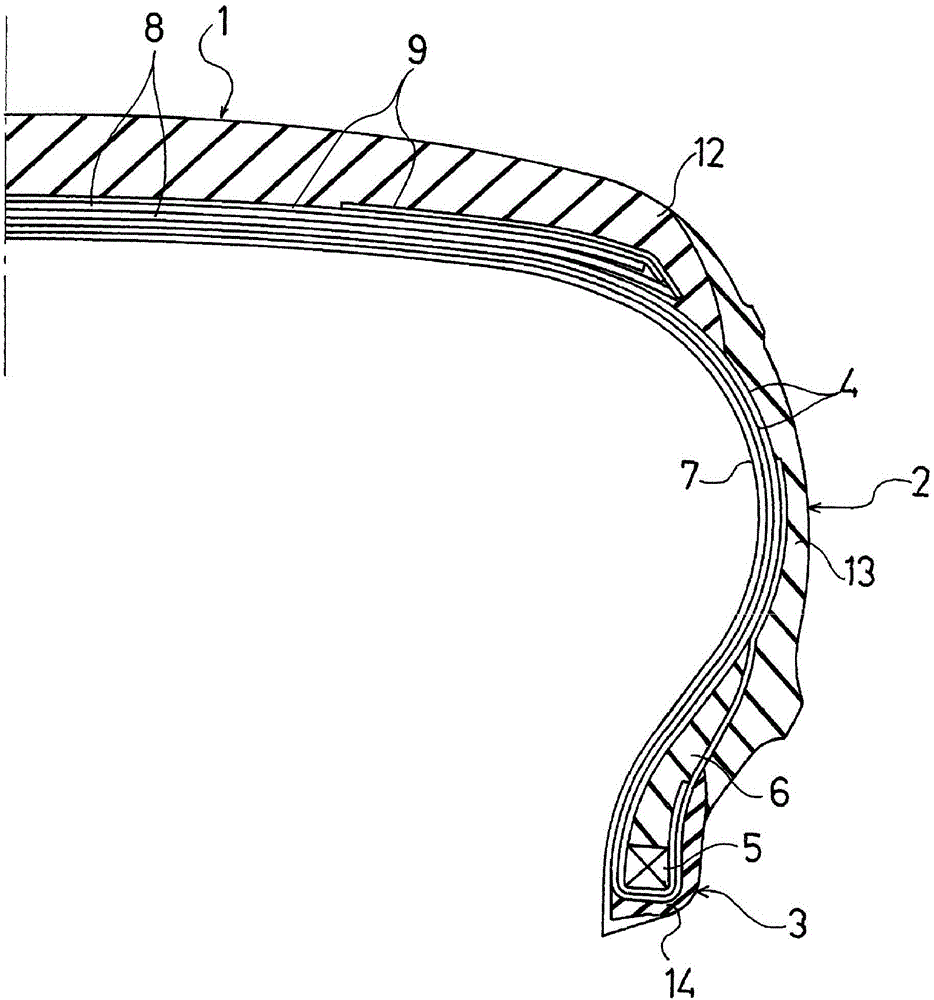

Image

Examples

Embodiment

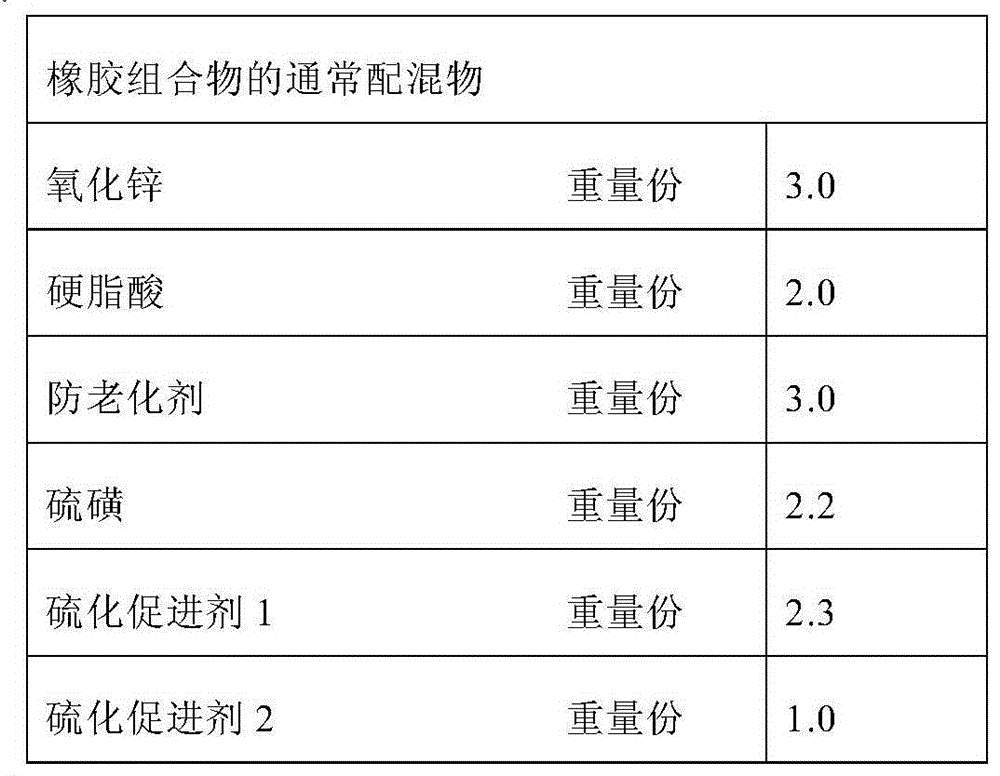

[0040] The compounding agent shown in Table 4 was used as a common compound, and 26 kinds of rubber compositions for tires (Examples 1-11, Comparative Examples 1-15) were prepared by the following method according to the raw material formulations shown in Tables 1-3: Components other than sulfur and the vulcanization accelerator were kneaded for 5 minutes in a 1.8 L closed mixer, and then the masterbatch was released, and sulfur and the vulcanization accelerator were added thereto, followed by kneading by an open tumbler. In addition, in Tables 1 to 3, since modified S-SBR4 and unmodified SBR contain 37.5 parts by weight of oil-extending oil, the column of compounding amount not only shows the actual compounding amount, but also shows in parentheses The net compounding amount of each SBR after removing the extended oil is shown. In addition, the blending amount of the aromatic oil is properly adjusted so that the total oil amount and / or rubber hardness in the rubber compositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com