A kind of preparation method of solution method silane grafting modified EPDM rubber

A technology of graft modification of EPDM rubber, which is applied in the field of preparation of EPDM graft modified EPDM rubber by solution method, can solve the problems of high synthesis cost, slow vulcanization speed of EPDM rubber, long branch Chain EPDM silane graft modification and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

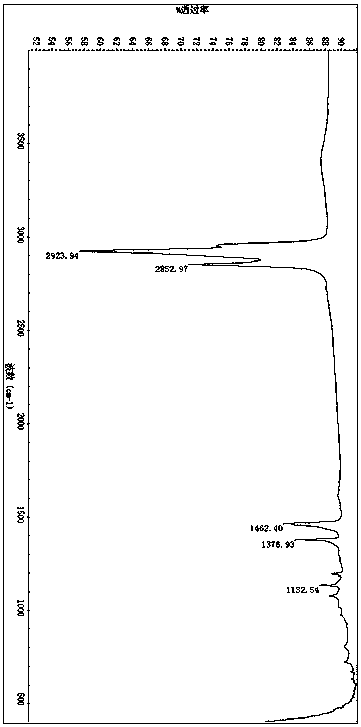

Image

Examples

Embodiment 1

[0018] Put 15g EPDM and 200ml cyclohexane into a 500ml three-necked flask, keep the temperature at 65°C, after EPDM is completely dissolved, raise the temperature to 85°C, slowly add 3.2g triethylsilane (Et3SiH), 0.6g acetanilide The cyclohexane solution, after the dropwise addition, stirred for 5 minutes, slowly added 3.2g of rhodium trichloride (RhCl(PPh3)3) into the three-necked flask within 20 minutes, and continued to react at constant temperature for 2 hours, and the reaction ended Finally, the product was poured out, added with anhydrous methanol for precipitation, settled for a period of time, filtered with suction, extracted with acetone for 12 hours, and dried in a 25°C oven for 12 hours under vacuum to obtain a transparent viscous solid product.

Embodiment 2

[0020] Put 15g EPDM and 200ml cyclohexane into a 500ml three-necked bottle, keep the temperature at 65°C, after the EPDM is completely dissolved, raise the temperature to 85°C, slowly add 1.8g triethylsilane (Et3SiH), 0.3g acetanilide After the dropwise addition, stir for 5 minutes, slowly drop 1.8 g of rhodium trichloride (RhCl(PPh3)3) into the there-necked flask within 20 minutes, continue to react at constant temperature for 2 hours, and the reaction ends Finally, the product was poured out, added with anhydrous methanol for precipitation, settled for a period of time, filtered with suction, extracted with acetone for 12 hours, and dried in a 25°C oven for 12 hours under vacuum to obtain a transparent viscous solid product.

Embodiment 3

[0022] Put 10g EPDM and 200ml cyclohexane into a 500ml three-necked bottle, keep the temperature at 65°C, after the EPDM is completely dissolved, raise the temperature to 85°C, slowly add 3.2g triethylsilane (Et3SiH), 0.6g acetanilide The cyclohexane solution, after the dropwise addition, stirred for 5 minutes, slowly added 3.2g of rhodium trichloride (RhCl(PPh3)3) into the three-necked flask within 20 minutes, and continued to react at constant temperature for 2 hours, and the reaction ended Finally, the product was poured out, added with anhydrous methanol for precipitation, settled for a period of time, filtered with suction, extracted with acetone for 12 hours, and dried in a 25°C oven for 12 hours under vacuum to obtain a transparent viscous solid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com